The new model filter paper teabag packaging machine has been developed and run in the tea packaging market this year. This new machine model is named ATB-S150 with advanced PLC control and an HMI display system. The whole machine unit is based on the old generation ATB-S120 machine model. The production performance has been improved sharply with various sensor-detecting systems equipped to facilitate the packaging process. This machine model is also applied to package granules or broken tea leaf products with good flowing features and product size within 20 ~ 60 meshes. Presently, this filter paper teabag packaging machine is mostly used to pack CTC tea, TBC tea, green broken tea, crushed herbal tea, medical granules, etc.

Technical Data

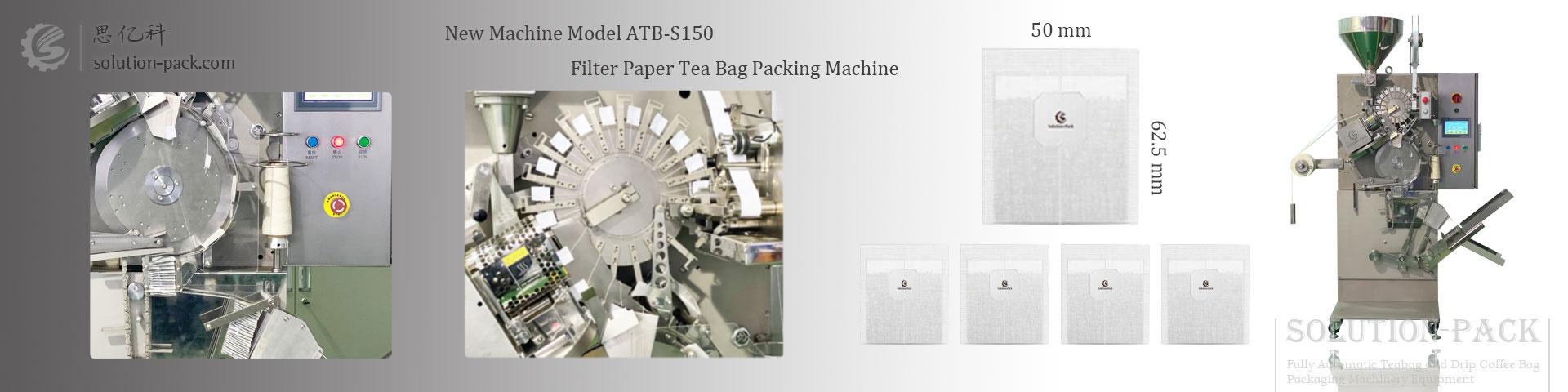

Machine Model: ATB-S150

Packing Volume: Max. 6 ml (Normally around 2 grams)

Packaging Material: Filter Paper Film (Heat-Seal Type)

Tea Bag Type: Naked Filter Teabag with Thread and Tag

Packaging Film Width: 125 mm

Filter Paper Tea Bag Size: 50 x 62.5 mm

Thread Length: 210 mm

Tag Size: 24 x 28 mm (Glue Seal Type)

Packing Speed: 120 ~ 140 Teabags/Minute

Power Supply: AC220V 1Phase 50/60Hz 1.5Kw

Machine Size: 1700mm x 800mm x 2000mm

Group Boxing Options: a. 10’s | b. 25’s/50’s/100’s | c. 20’s/40’s | d. 30’s/60’s

Optional Function: Heat-Seal Tag System; Vacuum Elevator System; Hopper Stirring System

Teabag Packaging Machine Typical Features

This new model teabag packaging equipment could realize quantitative tea product dosing, cotton thread/adhesive labels feeding, filter paper heat sealing, and automatic group counting output. The filter paper teabag packing machine does not have an envelope sachet function, but we improved the counting output and grouped the tea bags into a paper box which could save cost and be more efficient. The counting and boxing system has four kinds of pre-setting according to the tea bag quantities that need to be packed into the box. The boxing system is the manual type but meets the requirements of most tea production companies.

This high-speed teabag machine unit ensures low spare parts costs and maintenance costs. And we offer reasonable filter paper teabag machine prices with a compact machine size design. It is suitable for medium-sized businesses or group companies. And it could pack naked teabags with or without thread and tag in one machine. The machine frame is made of silver-coated carbon steel and the material contacting parts is made of food-level stainless steel to meet CE and GMP requirements. Advanced Panasonic PLC control system and Samkoon HMI display screen are equipped to facilitate production.

This filter paper teabag packaging machine could also connect with the automatic vacuum elevator system. Material level sensor shall be equipped to ensure that customer can feed material easily and saves material waste. Premium design with monitor and alarm for jam teabag, shortage of materials, empty bags, tag paper/thread, etc. The automatic failure shutdown system is also equipped to ensure safe production. We warmly welcome friends from all over the world to consult and Solution-Pack shall provide professional service for each client. If you want to deliver your material to us to test on the machine to check the performance, welcome to contact us immediately.

One Station Service | Find The Intelligent Teabag Packaging Machine Solution Here

With the pace of life growing faster and faster, more and more people choose the filter paper teabag instead of the traditional way of brewing tea. It is easier to carry and brew no matter whether traveling or at the office. Meanwhile, the market need for good quality teabag packaging equipment has grown up in recent years. Solution-Pack has focused on teabag packaging machines for over 12 years with rich experience and market research and offers different types of high-speed teabag machines to meet the market requirements.

To better support the client with the project, we supply sample material testing services for the client who is a start-up on the filter paper teabag machine project. Each client could deliver around 4 kg of sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange the machine to test the material and propose the most suitable inner and outer tea bag size for the client. In this way, it could better ensure the client gets the most accurate packaging data for their products. We could also supply the client with customized packaging materials.

Requesting An Official Quotation

If you need an official quotation document for your project, we shall work our best to support you. Please advise the below-required information in detail.

1. Prepared some clear pictures of the tea products that you need to pack;

2. Provide a clear picture of the final teabag that you want to produce;

3. Offer us clear data of how much weight you need to pack per teabag and how many teabags you need to produce per minute;

4. Do you prefer the glue seal tag system or the heat seal tag system;

5. How many teabags do you need to count per group;

6. Offer your official contact name, company name, company address, and official contact number to our official mailbox: simon@solution-pack.com