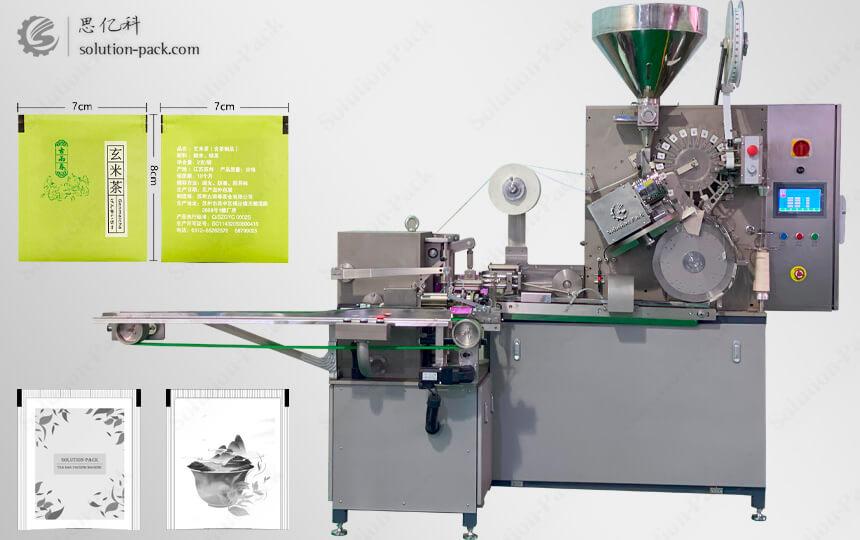

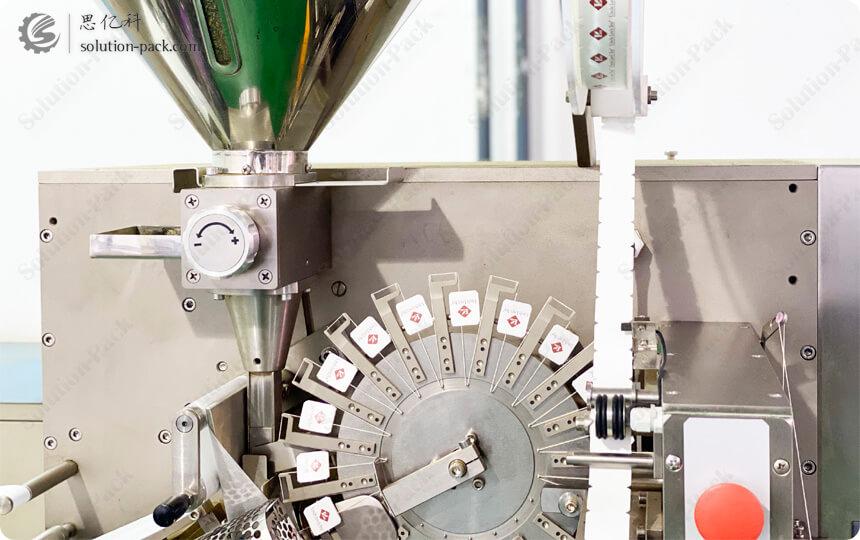

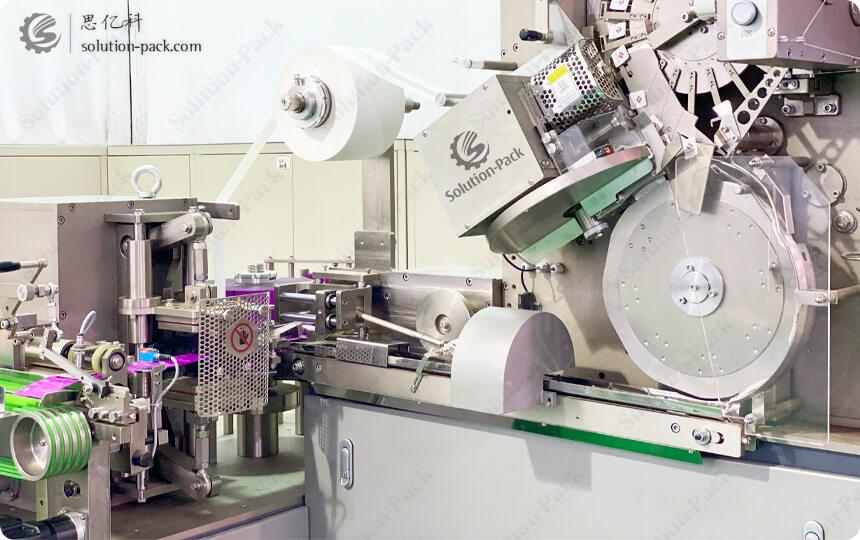

The foil sachet-wrapped filter paper teabag packaging machine is updated equipment. It integrates the inner filter paper teabag packaging system and the outer foil sachet wrapping system together to better protect the inner filter teabag from moisture and extend the lifetime of the final products. This teabag packing machine unit that we shall introduce today is the ATB-C6 machine model from Solution-Pack. This teabag machine could realize the function of automatic tea products cup dosing, tag feeding, thread feeding, filter paper film pulling forming, outer sachet film pulling, inserting inner teabag into the outer sachet, out sachet heat sealing, and finished sachets group counting output. The whole process is fully automatic with a stable production speed of 105 sachets per minute.

How does the teabag packaging machine work?

The ATB-6C machine model adopts the most advanced technology to realize the function of packing foil wrapped filter teabag with thread and tag automatically. The whole machine unit is controlled by the Panasonic PLC system developed by Solution-Pack. The colorful HMI interface adopts the Samkoon brand with Chinese and English language preset inside. The user could choose to equip a vacuum elevator to lift the tea products automatically. Then the teabag machine measures the tea products and follows the PLC system’s command to perform the packaging process until the final enveloped filter paper teabag sachets are counted and output. If the user only installs one machine unit, then it shall be more applicable to manually repack the grouped sachets into the paper box.

What are the advantages of the teabag packaging machine?

It could realize high production capacity and create high value for the users. Differing from the traditional food packaging machine, the teabag is normally smaller and needs more precise work which is a hard burden if only adopts manual work. The packing weight is generally around 1.5 ~ 2.5 grams per teabag, it shall take a lot of time for the labor to do it and the food safety issue will occur if adopting too many labors to work. However, all these concerns could be solved by adopting the teabag packing machine directly. It ensures the user with a stable production capacity of 105 sachets per minute. Each machine unit only requires one operator to run the machine and then repack the finished foil wrapped filter teabag into the box directly.

The whole machine frame is made of silver-coated carbon steel with great strength and the material contacting parts are made of food-level stainless steel to meet GMP production requirements. Full sets of detecting sensors and alarm systems are equipped to ensure smooth production and save waste during the packaging process. The machine shall alarm and stop automatically when the packaging films run out. Meanwhile, the empty teabag shall be rejected and collected before inserting it into the outer sachet. The safety door system could be chosen to protect the user and the machine shall stop once the operator opens the door during the packaging process. International famous brands of electrical and pneumatic parts are adopted to ensure the performance of the machine.

What can the teabag packaging machine work for?

The model ATB-C6 teabag packing machine is suitable for packaging 20 ~ 60 meshes of tea powder or granule products. Because the machine adopts a high-speed type volumetric cup dosing system, it requires that the material should be uniform to some extent so as to ensure packaging accuracy. Thus, it is not suitable for cutting tea leaves or herbal products. Presently, the teabag machine is widely applied in the market of CTC black tea, TBC tea, ground tea leaves, moringa tea, herbal tea powder, medicine tea, etc. This machine unit could dose a max. 6 ml volume of products, and it could hold around 2.0 grams of CTC tea as per our experience.

Requesting An Official Quotation

If you want to install a machine to produce foil wrapped filter paper teabag with thread and tag, we would be glad to support you. Please kindly advise on the below information.

1. What kind of tea product do you need to pack?

2. How much weight do you need to pack per teabag?

3. Do you have sample teabags at hand and could you provide the sample pictures?

4. When do you need to install the machine unit or if you need a budgetary quotation?

5. Please provide your official company name, address, and contact number. It would be much more convenient to send an email to our mailbox directly: simon@solution-pack.com