Instant drinks are becoming increasingly popular with the pace of life moving faster. It is more convenient and quicker to brew than the traditional drinks. Most instant drinks are packed in small sticks or sachet with standard weights ranging from 5 to 15 grams. Some factories package 250g, 500g, and 1kg centre-seal pillow bags or gusset bags and other factories choose to pack them into the pre-made doy pouch with ziplock. These package patterns could be sourced in the supermarket easily. We shall make a detailed introduction to the related packaging machine models that are applicable for producing these package patterns.

ECONOMICAL INSTANT DRINKS SACHET PACKAGING MACHINE SOLUTIONS

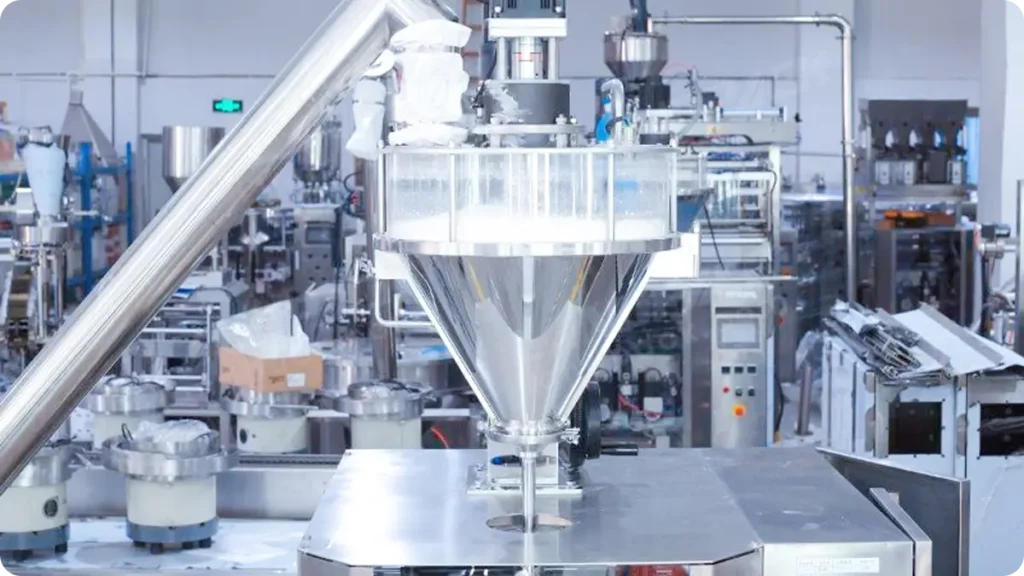

The instant drink products are mostly in powder or fined granule shape. The economical sachet packaging machine generally connects the auger screw weighing filling machine to package the material into the centre-seal sachets, 3-side seal sachets, or 4-side seal sachets. These machine models are specially designed for start-up factories, home businesses, or laboratories to make sample sachets. The equipment adopts an integrated design that could connect the auger screw elevator or vacuum elevator system to realize continuous production. The machine frame and the material contact parts are all made of SS304 stainless steel to meet sanitary production needs.

MULTI-TRACK INSTANT DRINKS SACHET PACKING MACHINE SOLUTIONS

Unlike the economical sachet packaging machine that produces around 35 sachets per minute, the multi-track sachet packaging machine equipment could produce a maximum of 250 ~ 300 sachets per minute. It is suitable for large factories to increase production capacity and save installation space. The advanced auger dosing filling system is controlled by servo motors with good performance and weighing accuracy. The multi-lane sachet packaging machine solution could connect with the sachet arranging conveyor system and the automatic boxing system to build up the whole packaging line.

STANDARD INSTANT DRINKS PACKAGING MACHINE SOLUTIONS

The standard instant drink products pillow-type bags, gusset-type bags, and stand-up pouches could be sourced easily in the market. It is more popular for home use because of the high volume of products inside. The vertical form-fill-seal packing machine solution could produce the centre-seal pillow/gusset bags with a stable 30-bags-per-minute capacity. The rotary pre-made pouch packaging machine could package the doy zipper pouch with 25 bags per minute. Both solutions shall accurately equip the advanced Panasonic servo motor-controlled auger dosing filling machine.

SUBMIT HERE TO CONTACT US

CHOOSE SOLUTION-PACK | SOURCE THE BEST INSTANT DRINKS PACKAGING MACHINE SOLUTION

- Solution-Pack is the leading intelligent flexible and industrial packaging equipment supplier from China with rich experience for over 12 years. We focus on providing mature and applicable packaging solutions for users to achieve the best production efficiency. Our principle is to work and study with the clients to analyze the project and find the most suitable packaging solution. We firmly believe that the more we confirm and prepare, the better we can work for the clients. Warmly welcome friends from all over the world to contact us to work on the packaging project.

- To better support the users in the machine installation process, we provide two options. When the user’s factory has a professional engineering team, we propose remote online WeChat video guidance installation. It could support the users to save installation costs. If the user is the first to use and install the machine unit, our engineer will fly to the site to do the installation work and train the operators. Both methods are available for option.

FAQ | INSTANT DRINKS PACKING MACHINE

How many sachets could the powder sachet packing machine produce?

It depends on the machine models that the users choose. The simple economical sachet packaging equipment could produce around 30 sachets per minute. The multi-track sachet packaging equipment could produce around 25 ~ 30 cuts per track per minute and the tracking quantities could design a maximum of 10 tracks for production. Meanwhile, the powder mesh size and flowing features also influence the filling speed. We shall study the users’ product features before offering proposal production capacity.

What kinds of sachet could the powder sachet packing machine produce?

Generally, the liquid sachet packaging equipment produces standard centre-seal sachet, 3-side seal sachet, and 4-side seal sachet. It could also produce abnormal-shaped sachets with customized cutting and sealing mould. Meanwhile, we could offer a leakage-proof design for the users’ sachet to ensure their product’s quality.

Which powder sachet packing machine brand is the best to use?

Solution-Pack offers mature and stable powder products packaging machine solutions for users worldwide with reliable performance. We firmly believe that the simpler the design, the better the user experience. We have researched to design suitable machine models for factory production. Welcome to send your inquiry to us to communicate about your project!