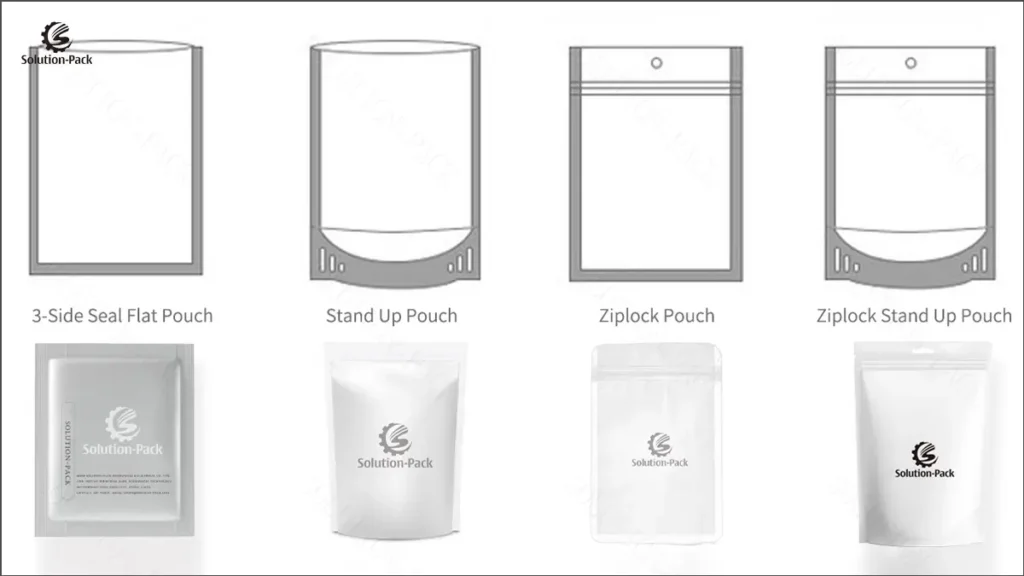

The pre-made pouches are popular in the international market for packaging food, seeds, grains, animal feed, and chemical products. Some pouches are in flat patterns, some are in bottom stand-up patterns, and some are in box patterns to meet the best marketing performance. They are more neat and beautiful than the pillow-shaped or gusset-shaped bags produced by the Vertical Packaging Machine. They are generally designed with zipper locks to allow users to re-close them easily after opening. They are mostly used for high-valued product packaging since they cost more than the general roll packaging films. Solution-Pack shall introduce the most popular 6 models of pre-made pouches packing machine solutions below to guide the manufacturers in selecting the correct machine model for production.

PRE-MADE POUCHES ROTARY PACKAGING MACHINE SOLUTIONS

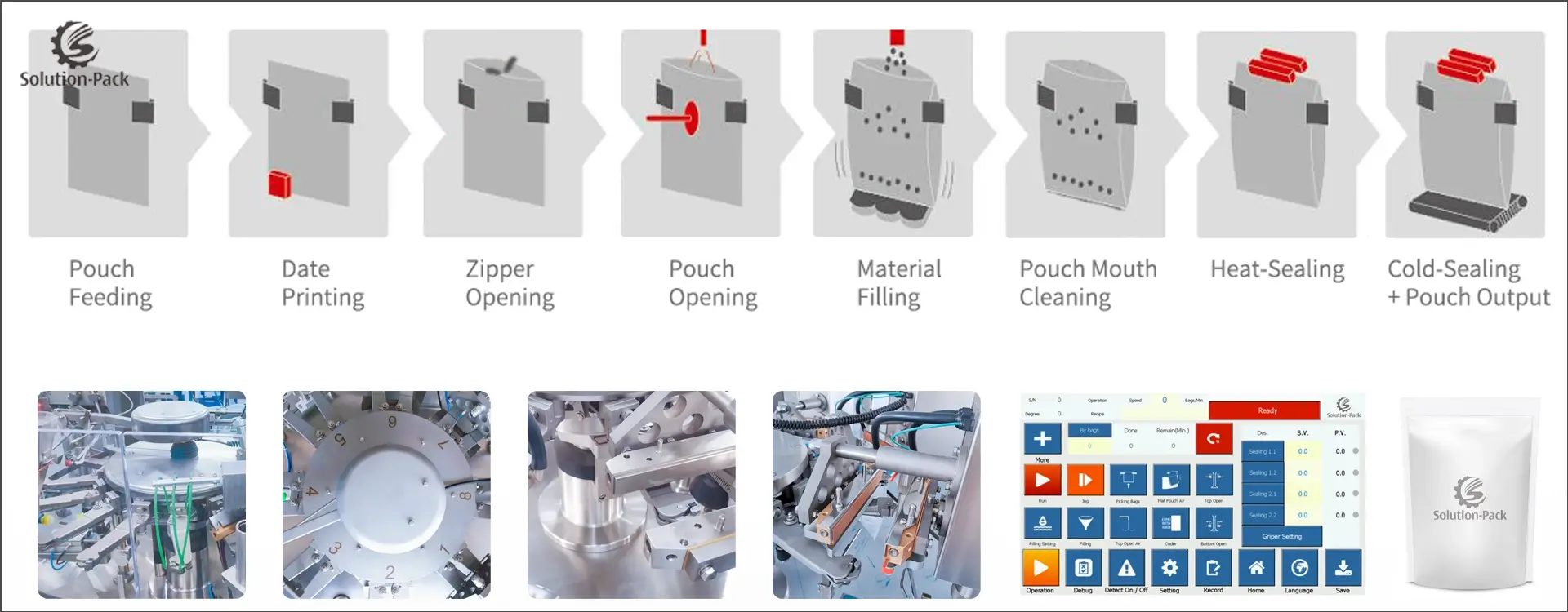

The rotary packaging machine unit could connect with different types of weighing filling systems to realize the function of packaging different materials. It could generally perform the actions of material elevating, material weighing, pouch feeding, zipper opening, date printing, pouch mouth and bottom opening, material filling, pouch mouth cleaning, heat-sealing, cold-sealing, and final pouches output. Additional functions like nitrogen gas filling, label stamping, or inkjet printing could be customized according to the user’s specific requirements. The pouch sizes could be adjusted freely on the HMI interface when the user needs to change different sizes of pouches for production.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE PRE-MADE POUCHES PACKING MACHINE SOLUTIONS

1.) Intelligent Design: The pre-made pouch packing machine unit adopts a compact structure design pattern to save installation space for the users. The whole machine frame and the material contacting parts all adopt the food-level stainless steel to meet the food production sanitary requirement. The surface of the machine is fully polished to ensure the best appearance and cleaning convenience. The safety door system uses a transparent Lexan board which allows the user to check the mechanical movements inside the machine easily;

2.) Advanced Configuration: As one of the professional doy pouch rotary packing machine manufacturers, Solution-Pack offers high-standard configuration for the users with a pleasant user experience. We adopt the smart Siemens PLC control with a 10-inch colourful HMI interface for convenient operation. The other related pneumatic and electrical parts also adopt AirTac, SMC, Schneider, or equal brands to facilitate the user to source the spare parts easily from the local market. Meanwhile, the user could also choose to purchase them from us directly;

3.) Customized Features: The zipper pouch packing machine could connect with different kinds of elevating and weighing systems to pack the target products and pouches. The pouch width “fast-to adjust” function is equipped and the users only need to press the “Gripper Setting” button on the HMI to set the target pouch width when they need to change the production recipe. The middle hopper system could be assembled to improve the filling speed, and the nitrogen gas filling function could be installed to extend the shelf-life of the final products.

GUIDANCE ON SELECTING THE SUITABLE STAND-UP POUCHES PACKING MACHINE SOLUTION

When we judge which doy bag packaging machine is suitable for the users’ production, the exact packaging materials shall be put in the first position. The liquid products shall use the liquid elevating and dosing filling pump system, the granule products shall use the Z-type bucket elevator and the multi-head weighing filling system or the linear head weighing filling system, and the powder material needs to use the screw elevator with the auger dosing filling system. Different kinds of materials have various features, and we need to study the material features first before moving forward to set down the final solution design. Mutual communication on the project details is required to ensure the most suitable and applicable equipment for the users.

The second point that influences the machine model chosen is the pouch width. Each model machine has a certain limitation range on the pouch width due to the mechanical design of the rotary panel. The 240 series machine could allow the max. 240 mm pouch width and max. 300 mm pouch length. The 300 series machine could allow the max. 300 mm pouch width and max. 350 mm pouch length. Some users may have different pouch widths and lengths to run on the same machine unit, so we need to check if all the pouch sizes can fit in one machine model to save the cost for the users. We warmly welcome friends from all over the world to communicate with us with project details!

CHOOSE SOLUTION-PACK | FIND THE BEST ROTARY BAG-GIVEN PACKING MACHINE EQUIPMENT

Solution-Pack is a leading packing machine manufacturer and trader in China with over 12 years of experience. We have professional assembling workers, technical teams, and marketing departments. Our major markets include snack foods, daily care products, cosmetics, tea, coffee, grains, seeds, animal feeds, pet foods, and chemical fertilizers. We treat each project seriously and comprehensively study users’ detailed requirements before proposing suitable and applicable packaging solutions. We offer high-standard machine equipment with official CE certification from ECM and all the goods will be packed in non-fumigation export wooden cases. Welcome friends worldwide to contact and work together with us to build up their projects!

After-sale service is the priority in our work and users’ experience is the top mission of our enterprise. When the equipment arrives at the user’s warehouse, we will send a professional engineer to the site for installation and training. Some users could use WeChat or WhatsApp to contact us for remote installation guidance for some simple machine models. The English version diagram and manual operation book will be delivered with the machine to support users in learning the machine before installation. What’s more, we could also help users in packaging film design works and choosing suitable packaging films to save costs for them.