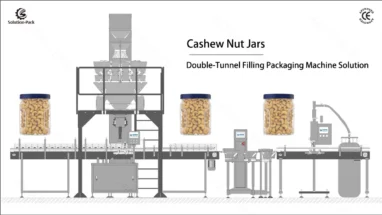

This cashew nuts jars packaging machine line is designed so that the nuts group companies can package nuts products into plastic jars automatically. It is presently used for packages of 450g, 454g, 500g, and 1000g of cashew nut products. The automatic liquid nitrogen filling system is equipped to support users in extending the shelf life of the final products. The double-tunnel feeding system ensures a stable production speed of 20 ~ 35 jars per minute. The advanced middle hopper system can better protect the cashew nuts in the measuring and filling process. Apart from cashew nuts, this nut packaging machine line could also be applied to peanuts, almonds, walnuts, hazelnuts, pistachios, etc.

WORKING PROCESS | CASHEW NUTS JARS PACKAGING MACHINE LINE

1.0) Manual Feeding Jars: This solution offers users a double-sided manual feeding conveyor. Most nut manufacturers have different weight specifications and jars in daily production. The manual feeding conveyor allows them to flexibly adjust the conveyor guiding system when changing to a new production specification. Meanwhile, the operators can simultaneously take charge of raw material feeding work and the machine operation job, saving labour costs and improving user production efficiency.

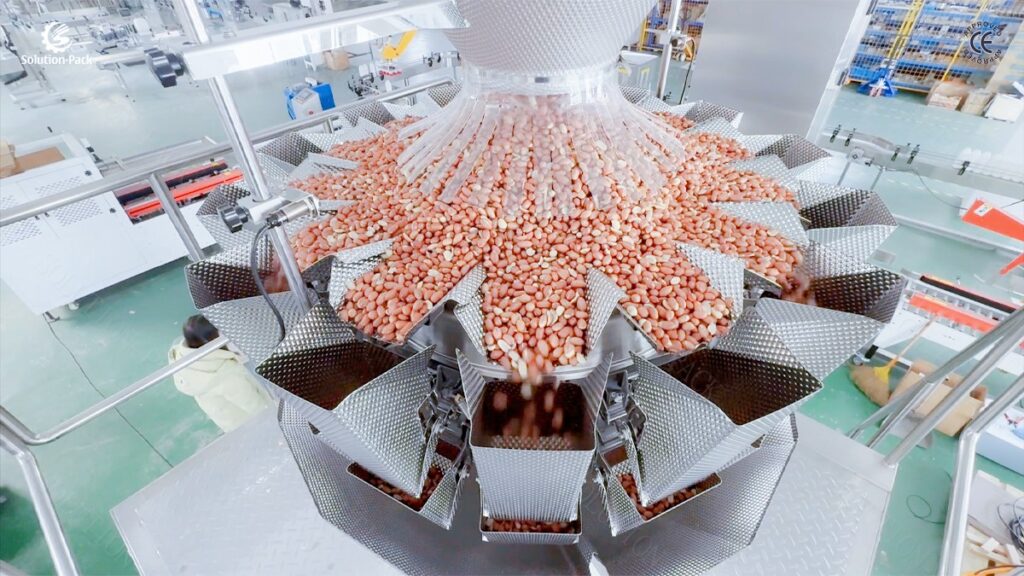

1.1) Multi-Head Weighing Filling System: The 14-head weighing filling system and Z-type bucket elevator are equipped for continuous production. A maintenance working platform supports the multi-head weighing machine. The middle hopper system is equipped to increase the measuring speed and protect the materials from breaking during the falling process. All the machine frame and material contact parts are made of food-level stainless steel to meet food production requirements.

1.2) Double-Tunnel Feeding System: This cashew nuts jars packaging machine adopts a double-tunnel feeding conveyor design. The material drops from the middle hopper directly into the jars to reduce the falling height. The photoelectric sensor detects the position of the jars, and the block device fixes the jars before filling. This cashew nuts packaging machine solution has been designed with two production speed modes for users. The normal packaging mode performs 20 jars per minute, and the fast packaging mode performs 35 jars per minute.

1.3) Weight Checking & Rejecting System: This customized packaging machine line adopts an advanced weight checking and rejecting system to ensure high-quality products are output and automatically kicks out unqualified jars. The smart load cell detects the jars’ weight accurately. The customized pushing rod protects the jars from falling down during the pushing process. The entire machine frame is made of food-grade stainless steel to meet the food production requirements.

1.4) Liquid Nitrogen Filling System: This system fills the jars with liquid nitrogen to extend the shelf life of the nuts. It operates using Siemens PLC control and an HMI interface. The HMI allows for the adjustment of the filling amounts and the height of the filling nozzle. The liquid nitrogen filling system should connect to the dewar tank, a special container for liquid gas products. It could better protect the nuts from oxidation than the gas state nitrogen filling solution.

SUBMIT HERE TO CONTACT US

PICTURES | CASHEW NUTS PACKAGING MACHINE SOLUTION

Choose Solution-Pack | The Best Cashew Nuts Jars Packaging Machine Solution

Solution-Pack provides customized nuts packaging machine solutions for worldwide users to realize simple and easy production. These solutions could automatically support users in packaging 200 ~ 1000 grams of nuts or similar granule products into plastic jars with high production capacity. Besides realizing the basic function of packaging, we also provide optional functions like metal detecting systems, weight-checking systems, unqualified bag-rejecting systems, and liquid nitrogen filling systems. The entire solution is customized to each user’s production requirements. Solution-Pack provides official CE certification for all equipment.

We offer two types of options according to the user’s needs. The first option is an on-site installation and training service. It is suitable for users who use automatic packaging machine solutions for the first time and require detailed instructions to support the operators. We shall send engineers to the site to support the installation and training work. The second option is a remote online installation and training service. It is suitable for users familiar with the packaging machine equipment and who have professional technicians. We will do this work via WhatsApp or WeChat. No matter which option users choose, we shall create an after-service group for users to communicate instantly.