Introduction of Detergent Powder Packaging Machine Solution

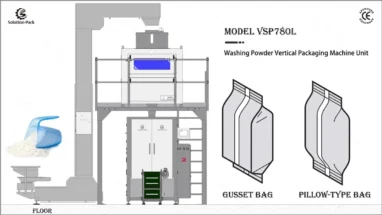

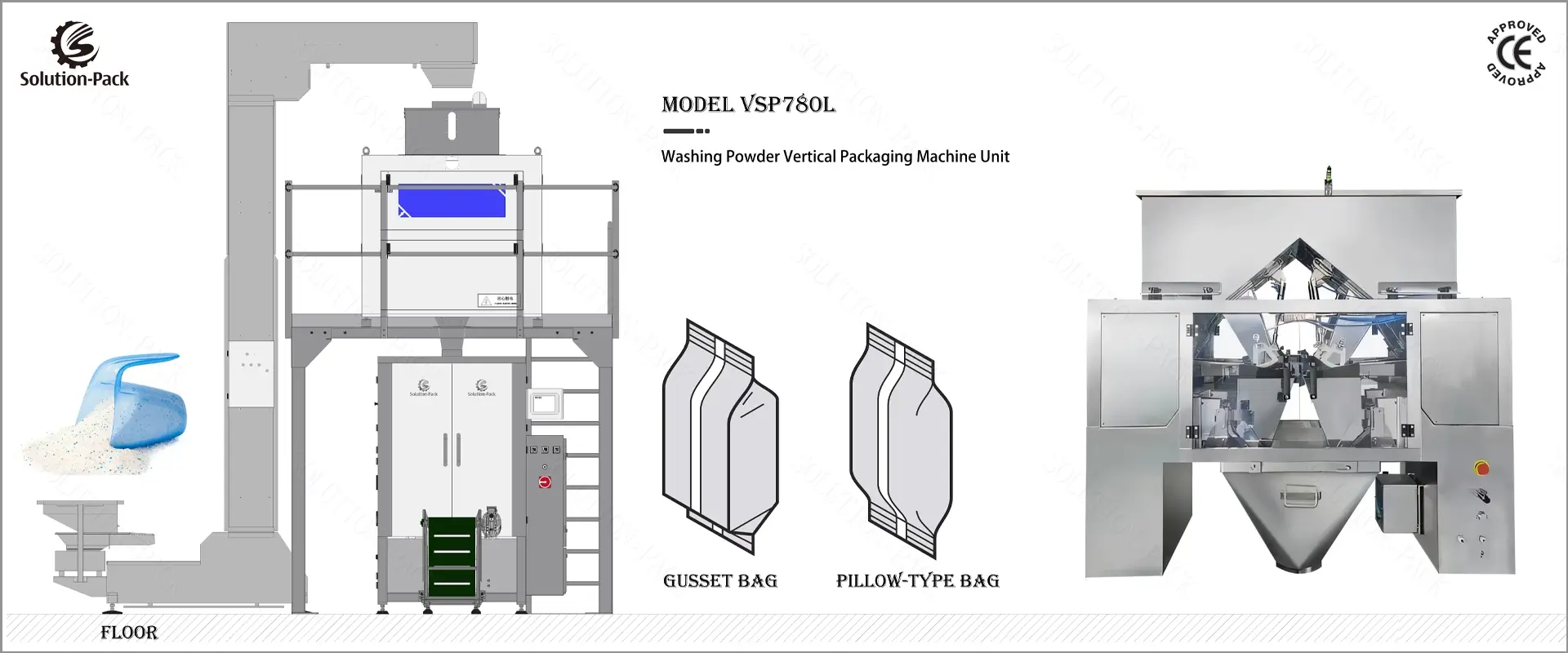

The VSP780L automatic detergent powder packaging machine solution focuses on packaging 2-6kg of washing powder material into bags. This solution comprises the Z-type bucket elevator, a customised linear weighing filling machine, a maintenance working platform, a VSP780 vertical packaging machine, and a product output conveyor. It could realise the functions of automatic material elevating, weighing, bag forming, material filling, heat sealing, and final bag output. Generally, the vertical packaging machine can support users in producing 15-30 bags per minute with stable running performance. The system features a side-gusset device, enabling users to package Pillow-Type Bags and Gusset-Type Bags on the same machine unit with ease.

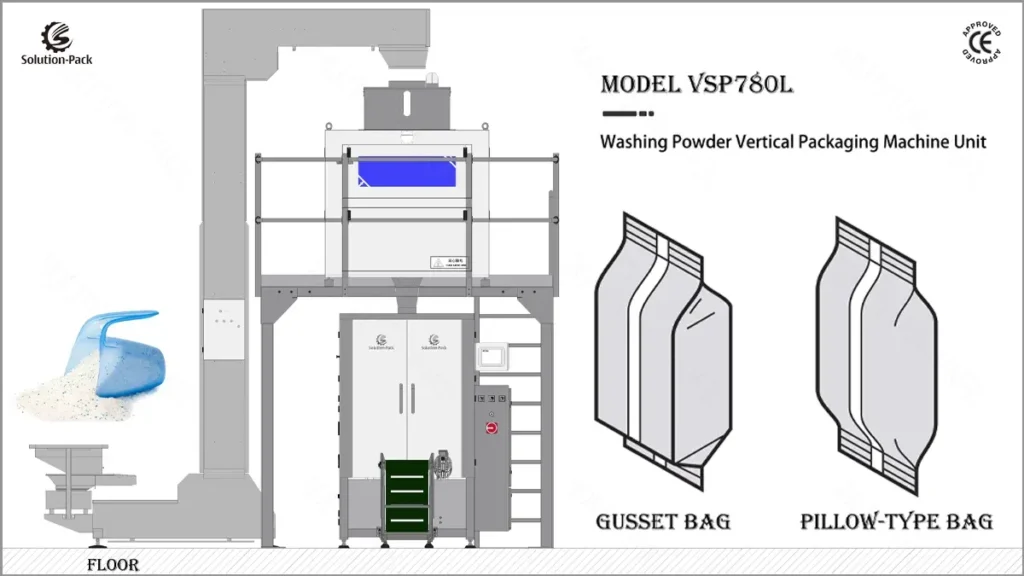

Brief Technical Data of the Washing Powder Packing Machine Solution

Compared to family-use washing powder products, industrial detergent powder is denser in bulk. The bulk density of regular washing powder is approximately 0.28-0.45 g/ml, while industrial washing powder has a bulk density of around 0.66-1.04 g/ml due to its formula and processing. The VSP780L washing powder vertical packaging machine solution features a 6-hopper linear weighing and filling system, with each hopper having a volume of approximately 8 litres. A large volume can better hold the material and effectively improve production efficiency. The Z-type bucket elevator utilises 4-litre hoppers to achieve an elevating capacity of 6-10 cubic meters per hour, enabling continuous production.

Advanced Features of VSP780L Automatic Vertical Packaging Machine Unit

High-Standard Configuration: This vertical packaging machine unit features SS304 stainless steel for all material-contacting parts, with the other frame parts made of coated carbon steel, ensuring compliance with international standards. The majority of the pneumatic and electric components utilise internationally renowned brands, including Omron, Schneider, AirTac, Siemens, and Innovance, among others. The standard HMI interface operating system has been designed in two languages: Chinese and English. All the electrical connection ports utilise circular connectors to facilitate installation and daily maintenance work.

Easy Operation: The forming collar system is designed as a whole unit. When users need to package different weight specifications, they only need to remove the original forming collar device and install the new one on the machine. The advanced PLC control system can support users in storing the packaging data as recipes. They only need to change the recipes on the HMI interface when packaging different weight specifications. The machine shall automatically stop and alarm in the event of a failure. The auto-diagnosis system displays the issue on the alarm page, allowing users to check the failure easily.

Stable Running Performance: This detergent powder packaging machine solution adopts servo motors and drivers for the film pulling and heat-sealing function. This method is more stable and produces smoother, neater, and more beautiful bag patterns compared to the traditional cylinder control system. The linear weighing filling machine system features crude and fine feeding tunnels, equipped with a Transcell loadcall control, to ensure precise dosing accuracy. The system shall operate in a combination dosing mode when the single hopper is unable to hold a single bag of material.

SUBMIT HERE TO CONTACT US

CHOOSE SOLUTION-PACK | SOURCE THE BEST DETERGENT POWDER PACKAGING MACHINE SOLUTIONS

Solution-Pack is China’s leading supplier of intelligent, flexible, and industrial packaging equipment, with over 12 years of experience. We focus on providing mature and practical packaging machine solutions that enable users to achieve optimal production efficiency. Our principle is to work closely with clients to analyse the project and find the most suitable packaging solution with CE certification, whether they are just starting up in the packaging business or need to renew their existing packaging line. The more we confirm and prepare, the better we can serve our clients. We warmly welcome friends from all over the world to contact us about potential packaging projects.

The after-sales service is what most clients are concerned about in the machine project. To better support users during the machine installation process, Solution-Pack offers two options. When the user’s factory has a professional engineering team, we propose remote online WeChat video guidance installation. It could help users save on installation costs. If the user is the first to use and install the machine unit, our engineer will fly to the site to do the installation work and train the operators. It can help users better understand the machine’s operating principle and maintain it correctly in daily production. Both methods are available as an option.

FAQ | WASHING POWDER AUTOMATIC VERTICAL PACKING MACHINE SOLUTION

How to source the correct washing powder packaging machine solution?

Before sourcing a packaging machine solution for detergent powder, the manufacturer needs to conduct market research to clarify the packaging data, including bag patterns, packaging weight, roll film width, bag length, and target production capacity. Then contact Solution-Pack and provide this information to them to request an official quotation. They will follow the detailed packaging requirements to ensure the installation layout design is effective, and provide a price list for the user’s review. The professional service they offer will surely give you a clear idea of the project.

What’s the difference between household detergent powder and industrial laundry detergent?

Household detergent powder contains a smaller proportion of active substances and ingredients than industrial laundry detergent. Additionally, industrial laundry detergents have different formulas for various types of linen and dirt, which are highly targeted to specific types of stains. The washing procedures and the temperature of the washing water differ when washing linens with household laundry detergent compared to industrial laundry detergent. Household clothes are generally washed in cold water, either in a washing machine or by hand.

How does the washing powder vertical packing machine work?

The washing powder vertical packing machine solution typically comprises an elevator, a weighing and filling machine, a working platform, a vertical form-fill-seal packing machine, and a product output conveyor. It can realise the function of automatic material elevating, weighing, film pulling, bag forming, material filling, heat-sealing, hand hole punching, and final product taking out. The entire machine unit requires only one labourer for operation and can package 15-30 bags per minute, offering stable performance for users. Check our video on YouTube!