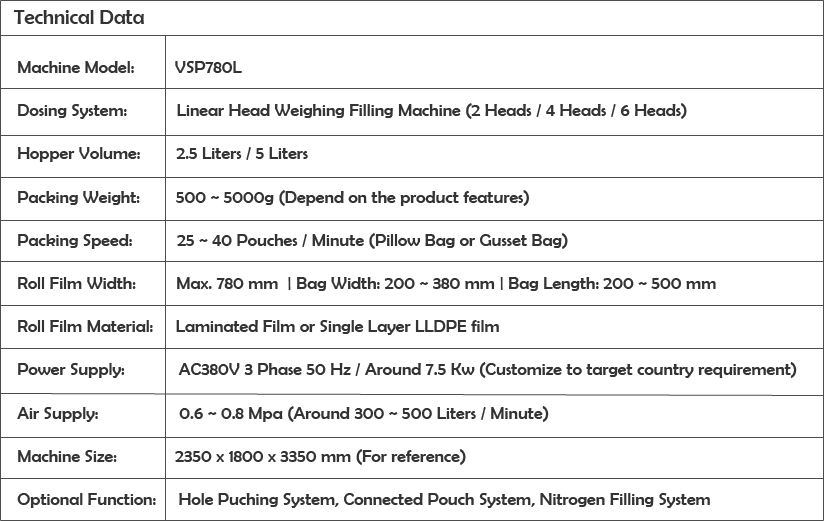

About VSP780 Vertical Form Fill Seal Machine

The model VSP780L automatic vertical form fill seal machine unit is a big machine for packaging 500g to 5kg granule or particles materials into a pillow-type or gusset-type bag. The vertical packing machine unit is connected to the linear weighing filling system to realize the automatic production process. The user could choose to equip the Z-type bucket elevator or connect directly with the raw material silo to ensure enough material level for continuous packaging. This vertical form fill seal packing machine solution could produce around 25 ~ 40 bags per minute per material feature. And t is widely applied to packaging washing powder, seeds, oatmeal, rice, grains, broken tea leaf, etc products with good flowing features.

Typical Features of VSP780L Vertical Packaging Machine

Exquisite Appearance

This vertical form fill seal machine unit adopts food-level stainless steel for the frame and material contacting parts which conform to the food QS and pharmaceutical GMP health requirements. All the steel surfaces choose the polishing process to prevent the handprint and keep neat. The transparent Lexan board safety door system is used to ensure the user checks the mechanical movement inside the machine even when the machine is in the working process.

High-Standard Configuration

To ensure providing the best quality packaging machine products for the user, Solution-Pack chooses internationally famous brand pneumatic and electrical parts for a stable machine running performance. The PLC control and HMI interface adopt the Siemens brand. The other pneumatic and electrical parts adopt Schneider, SMC, AirTac, Omron, or equal brands to facilitate the user to source spare parts easily from the local market. And the user could also get from us directly.

Customized Functions

The vertical pouch packing machine shall customize according to the user’s product features and requirements. The elevating system shall be decided by the product features, and the weighing system shall depend on the user’s production capacity requirements. The pouch sealing style shall follow the user’s sample bags or design. The weight checker & metal detector system and the unqualified products kick-off system could also be equipped as per production needs.

Key Advantages of VSP780L Vertical Packing Machine

The vertical form fill seal machine mainly is equipped with safety protection which is in line with the requirements of enterprises’ safety requirements. The film drawing system and the color code control system could be automatically adjusted on the HMI which allows simple operation for sealing and notching functions. The touch screen could store a variety of packaging process parameters of different products and can be used at any time without adjustment when replacing products. The vertical form fill seal packaging machine is equipped with a fault display system, which can help troubleshoot in time and reduce the requirement for manual operation. The machine adopts a closed structure to prevent dust from entering the machine effectively. And it could produce pillow bags, gusset bags, hanging bags, and string bags according to the production requirements.

What is the difference between horizontal and vertical form fill seal?

Vertical form fill seal packing machine involves the sealing of product on a vertical plane, going from up to down in which ends are cut from bottom to top. Horizontal form fill and seal involves the sealing of the product by sliding on a horizontal plane in which ends are cut from side to side.

What is the vertical form fill seal packing machine process?

Vertical form fill seal packaging is the packaging form that is a way to form the wrapping film in a tube shape, drop the product in the vertical direction, and then form a pillow-shaped bag. The above picture shows the packing process. The typical products wrapped in VFFS machines are snacks, sweets like chocolates and candies, frozen foods, frozen vegetables, powder products of coffee, cocoa, milk, starch, seasoning mix, and pharmaceutical products such as barium powder.

Why Cooperate with Solution-Pack?

Solution-Pack is one of the leading vertical form fill seal machine manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. The VSP780L machine model supplied by us could perform both gusset bag packaging and pillow bag packaging by taking around 10 minutes to change the bag forming collar system. And it allows the user to pack both uniform or irregular granule materials at a stable production speed of 25 ~ 40 bags per minute according to the product’s features and additional functions requirements. You will surely get the most suitable machine solution for your project if you choose to cooperate with Solution-Pack.

How about the after-sale service from Solution-Pack?

We provide two types of after-sale service systems for the client under different conditions. If the user has a professional engineering team, we propose the online instructing installation service. We shall open the WeChat video online when the machine arrived at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, if the user is for the first time to install the machine and without any knowledge of packaging machines, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.