The HTB-Z50BS automatic weighing bagging palletizing machine line is an industrial heavy-duty bag packaging production line. It mainly focuses on packaging M-Type coated pp woven sacks or kraft paper bags and then palletizing them on the pallet automatically. The single automatic bagging machine line could perform the production capacity of 600 bags per hour and it could also combine two bagging machines together with one robot palletizer to improve the packing speed to 1200 bags per hour. This woven sack bagging palletizing production line is widely applied in animal feed, aqua feed, feed additives, urea granules, chemical fertilizer, grains, seeds, and other small granule food products.

Features of Automatic Weighing Bagging Palletizing Machine Solution

This fully automatic bagging and palletizing machine line is one of the typical robotic bagging systems in the market. It could support the producer to connect with the raw material silo to realize the function of automatic weighing, bag feeding, bag clamping, material feeding, bag mouth folding, stitching, weight checking, pallet dispatching, robot palletizing, pallet wrapping, and final pallet carrying away. The whole production line only requires one manual to prepare the empty bags into the bag magazine of the 50kg bagging machine. The rest of the production shall realize a fully unmanned production process. The whole production line is customized to the user’s requirements and other ancillary equipment could be connected in the line as per requirements.

This pp woven bag packaging system adopts a high-standard configuration with all the PLC control and HMI display adopting industrial Germany Siemens brand. The other electrical and pneumatic parts also use internationally famous brands like SMC Cylinders, SMC Solenoid Valves, Becker Vacuum Pumps, Siemens Servo Motors, Mettler Toledo Load Cells, Schneider Indicators, Omron Proximity Switches, etc. It could facilitate the user to source the easy tear spare parts from the local market easily although the user could purchase from Solution-Pack directly. The whole machine frame is made of coated carbon steel and the material contacting parts is built of stainless steel.

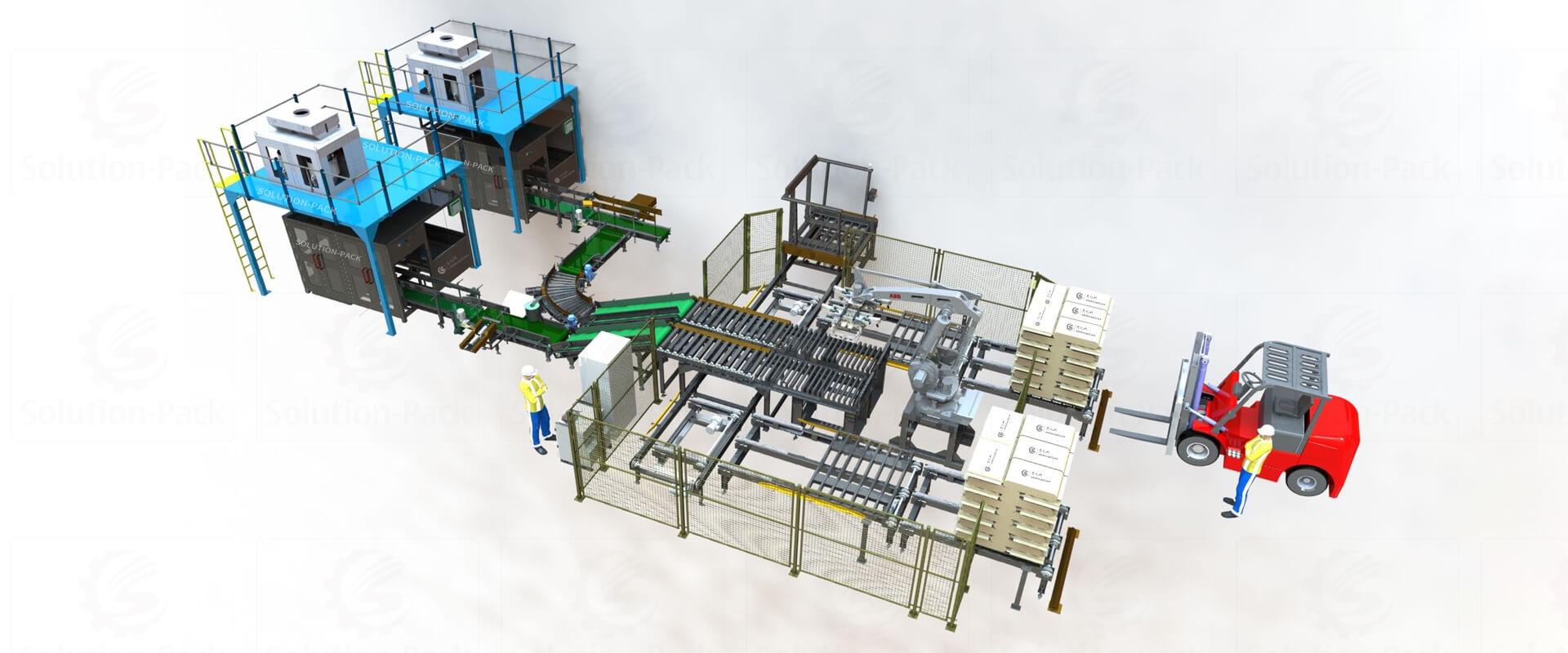

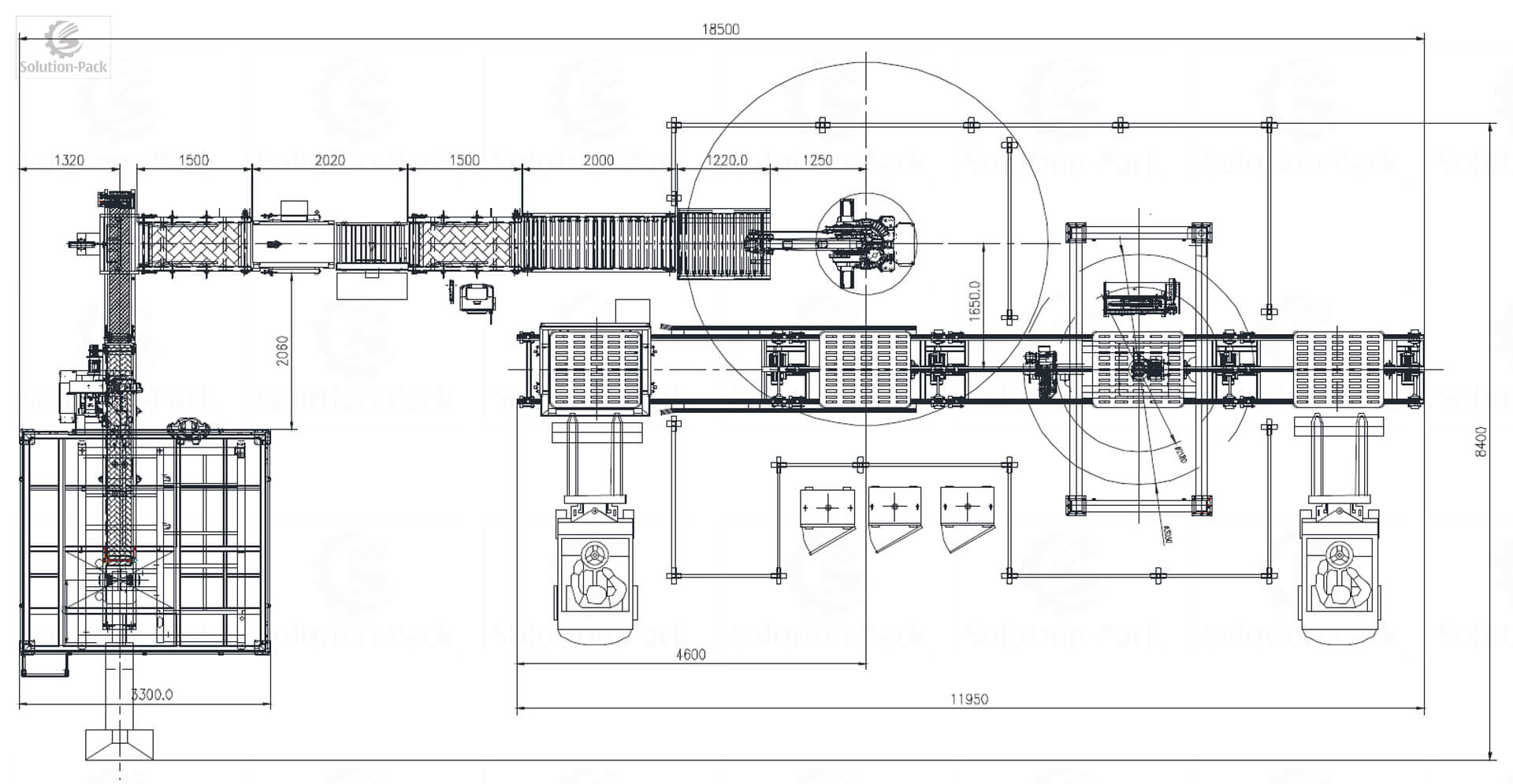

Reference Bagging Machine & Bag Palletizers Layout Design

Customized Solution Design

This bagging palletizing production line is a customized bagging machine line that needs to design according to each user’s specific requirements and product features. There are different kinds of ancillary equipment like metal detectors, check weigher, inkjet printers, pallet wrapping systems, pallet bundling systems, etc for the user to choose as per production needs. The whole production line layout design shall also follow the available space of the user’s factory to make to ensure the most efficient space occupation. The bagging machine parts could also be customized to connect with the user’s dosing machine if the second platform is already built.

Life-Long Technical Service

As for all the bagging sealing palleting machine lines from Solution-Pack, we shall send the professional engineer to the user’s warehouse to do the installation and training work for over half a month time to ensure the operator gets the operation and maintenance skills. One-year easy tear parts shall be prepared and delivered with the machine together for the user. And we shall provide life-long technical service for the user whenever they meet issues in machine operation or further spare parts stocking. Each machine unit shall have specific tracking no. to ensure the correct service in future maintenance work.

More Detail View of the Production Line

FAQ about The Weighing Bagging Palletizing Machine

What is a bagging palletizing machine?

The industrial bagging and palletizing machine is a packaging solution to bag bulk material into woven sacks and then use the robot palletizer machine to palletize them on wooden or plastic pallets for easy marketing and transportation.

What is a palletizing system?

A palletizing system is a mechanized machine that follows the order from the PLC to stack the products onto the pallet in a preset pattern. Changing the grasping hand, it could work for both bags, cartons, or even buckets.

How to choose the bag palletizer model?

The bag palletizer model is normally decided by the front-line production capacity. Generally speaking, the bigger the model is, the higher the working capacity.