The urea granule fertilizer is the most commonly adopted fertilizer product in agriculture plantations. The majority of the fertilizer factories chose to stock this product to meet the market needs. The urea bagging machine could support these factories to realize the intelligent packaging process with high production capacity. There are different kinds of urea bag packing machines according to different users’ production needs. Please read below the detailed introduction for different kinds of packaging types and the application range.

UREA BAGGING MACHINE OPTIONS

CHOOSE THE SUITABLE PACKAGING SOLUTION

The HZ25B/50B manual packaging solutions are applicable for all types of heavy-duty bags with customized sealing systems. These manual bagging sewing machine solutions are suitable for start-up factories with limited production needs. The users could choose the single machine unit to connect with an industrial slope elevator for truck loading directly or they could equip the automatic robot palletizing system to stock all the packed bags for a better market price. Generally, these manual packaging systems could perform a stable running speed of 360 ~ 480 bags per hour according to the skill level of the worker.

The HTB-Z25B/50B automatic flat bag bagging packaging solutions are applicable for the flat type PP Woven Sack or Kraft Paper Sack with a PE layer inside or outside of the bag. These automatic industrial bagging equipment adopt a vacuum-sucking system to pick up and feed the bag to the bag clamping device. Thus, they have restrictions on the bag qualities and sizes which could be checked on each solution’s introduction page directly. Compared with the manual type machines, the automatic bagging solutions could support the user to produce 600 bags per hour with only one labor to operate the machine.

The HTB-Z25BS/50BS automatic M-type bag bagging packaging solutions are suitable for the M-Side PP Woven Sacks or Kraft Paper Sacks. The PE layer is also required for the vacuum bag feeding system. Compared with flat-type bag solutions, these automatic urea bagging machines adopt a unique design in the bag clamping and conveying parts to ensure the best stitching performance. These types of packaging systems could also produce 600 bags per hour with one labor to prepare the empty bag into the bag magazine. There is no best solution, only the suitable system that makes it.

BENEFITS OF OUR INTEGRATED INDUSTRIAL BAGGING MACHINE SOLUTIONS

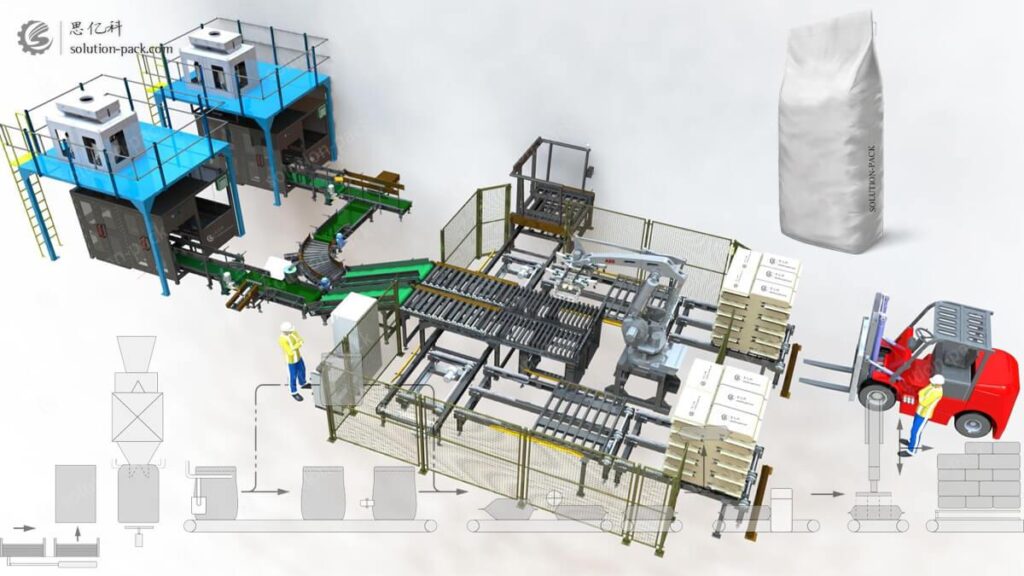

As one of the leading industrial bagging palletizing solution providers in China, Solution-Pack offers expert advice and 7 x 24-hour support for your packaging and manufacturing process. To better simplify your planning process, we supply customized packaging machine solution layout designs for your reference. All our equipment use the advanced Siemens PLC control system to realize centralized management of all devices. Meanwhile, all components are specially designed for your space and needs with great reliability. The simplification of project management allows you to handle all the things with one partner directly.