The HTB-Z50BS weighing bagging machine unit is an automatic bagging stitching machine system focused on M-type woven sack heavy-duty packaging. This pp woven sack bagging sewing machine could realize the function of automatic bag feeding, material dosing, bag mouth opening, material feeding, bag mouth gusset, bag mouth stitching, and final bag conveying out. The progress runs automatically and only requires one manual to prepare the pp woven bags into the bag magazine. It could support the user to produce around 600 bags per now with stable performance. This bagging system is now widely applied to grains, seeds, fertilizer, animal feed, aqua feed, chemical granules, and plastic granules market to improve production efficiency and save labor costs.

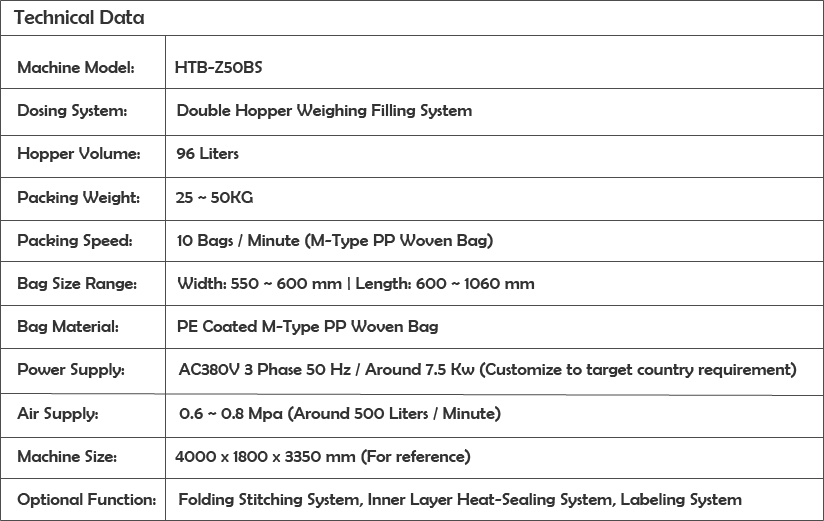

Features of HTB-Z50BS Weighing Bagging Machine

This M-type PP Woven Sack bagging machine solution is composed of the double hopper dosing filling system, maintenance platform, bag magazine, bag feeding system, bag clamping system, bag gusset system, heavy-duty conveyor, and stitching system. It is specially designed for M-type PP Woven Bag 50 kg packaging and sealing. The bagging sewing machine part adopts an integrated design style for easy machine installation and saving space. The intelligent safety door system is equipped to ensure immediate machine stop and alarm once the operate open door during the machine running time.

The bagging stitching machine solution uses a high-standard configuration to ensure stable running performance. Full series Siemens PLC & HMI control and display are equipped with CH/EN double language interface for easy operation. And customized language could also be required. Other pneumatic and electrical parts like SMC Cylinder, SMC Solenoid Valve, Becker Vacuum Pump, Schneider Relay, and Schneider Servo Motor are used to ensure the user sourcing the spare parts easily at the local market. The whole machine frame shall be made of coated carbon steel with great strength and the material contact parts shall be made of stainless steel.

The automatic weighing and bagging machine requires the PP Woven Sack to be coated with a PE layer inside or outside of the bag. Only in this way, could the vacuum sucker grasp and feed the bag to the bag clamp system successfully. The HTB-Z50BS machine model is only suitable for the M-Type PP Woven Bag, and the user could choose model HTB-Z50B to pack the flat-type PP Woven Sack according to production needs.

FAQ about the Automatic Bagging Machine Solution

How does the automatic PP Woven Bag Packaging Machine work?

The weighing filling machine shall dose the bulk material, and the bagging machine shall feed the pp woven sack to the bag clamp system. When the bag clamp system is in position, it delivers the signal to the weighing system to release the bulk material into the sack. After the filling process is finished, the bag shall drop into the conveyor system and transit to the sewing machine for stitching the bag mouth directly.

What type of woven sack is workable on the automatic bagging machine?

The automatic bagging machine requires the pp woven sack to be PE coated to be adaptable to the vacuum sucker bag feeding system. The PE layer could be coated inside or outside of the bag, and it could also be an independent layer inside the bag. Meanwhile, the user could also deliver the sample bags to Solution-Pack and we shall make the final confirmation for him.

How to seal the pp woven sack?

There are different kinds of sealing functions available for sealing the pp woven sack. For example, single-lane stitching, double lanes stitching, folding stitching, stitching + paper wrapping + heat sealing, paper wrapping + stitching… The sewing style is fully customized to each user’s specific requirements.