The model HZ50B double hopper manual bagging machine solution is an integrated industrial weighing bagging palletizing line for 25~50 kg bulk products. This weighing bagging machine solution only requires one laborer to feed the woven bags to the bag clamp system and then press the hand switch or foot switch to feed material into the woven sack directly. After the material is filled and ready, the manual just needs to flatten the bag’s mouth and send it into the chain guide of the stitching machine to realize the sewing process. The user could choose to connect to the automatic robot palletizer system or just end at the bag conveying out part.

Features of the Manual Bagging Machine

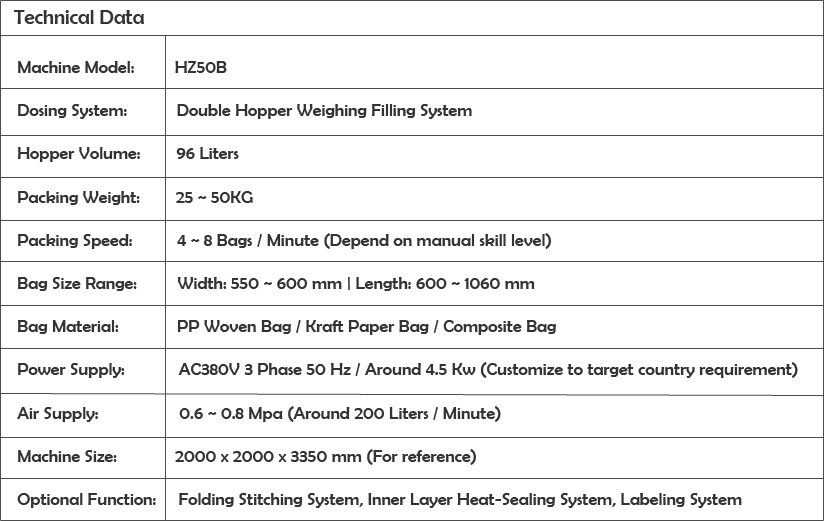

The HZ50B manual bagging sewing machine solution is independently developed by Solution-Pack to support small and medium-sized factories in realizing the function of bulk materials weighing bagging and sewing with a production capacity of around 4 ~ 8 bags per minute. The weighing dosing system adopts the double hopper weighing machine with the Mettler Toledo load cell to ensure packaging accuracy. The whole machine frame is built of coated carbon steel with great strength and the material contacting parts is made of stainless steel. The user could choose to equip the maintenance working platform or just use the floor stand weighing filling machine directly.

The belt conveyor adopts a heavy-duty design with an automatic lift-up and down function. This design style could allow the user to adjust the height easily when he needs to change between different lengths of bags. And the sewing machine is designed with a useful chain guide to facilitate the user to send the bag mouth part to the stitching position easily. Compared with the traditional stitching machine which requires the manual to operate very close to the sewing needle, this kind of design could better protect the operator in production process. Both the PLC system and the HMI shall use the Germany Siemens brand with the best running performance.

To better facilitate the user, we offer a one-stop station service for the user to build up the integrated bagging palletizing production line. The rest of the production line is mainly composed of the bag-down conveyor system, weight checker and rejecting system, bag flattening conveyor system, robot grasper conveyor system, ABB robot, and full line control cabinet. Compared with the automatic bagging machine, this solution also just needs one operator, and only the production speed is lower. But it is more applicable to most start-up factories or with limited budgets.

FAQ about the Manual Bagging Machine Solution

What’s the price of the manual weighing bagging machine?

The semi-automatic manual bagging machine cost is decided by how the user needs to equip the system. Solution-Pack shall support the user to analyze the product features and then propose a suitable weighing and sealing system for him. When the solution design and all technical data are confirmed well, we shall prepare the official quotation document for the user to check in detail. Compared with normal price competition in the market, we focus more on technical communication to ensure the packaging solution meets the user’s requirements well.

How to install the manual weighing stitching machine?

To better support the user with installation service, we provide two choices for the user according to their technical situation. If the user has a professional technical engineer, we propose remote online video instruction installation which may take 3 ~ 5 days for installation and training work. If the user does not have a technical team, we shall arrange for our engineer to travel abroad to conduct the training and installation work. Normally it shall take around 7 ~ 10 days for the whole time and the user needs to pay for the visa, round trip cost, accommodation, food, salary, and safety insurance. Unlike the automatic bagging weighing machine which is more complicated, most of the users choose the remote online installation for the manual bagging machine system.

How to build up a manual bagging palletizing production line?

Solution-Pack provides a one-stop station service for the users to design a full production line for them directly. We only require the users to offer detailed requirements before we start the layout design work. Generally, the final layout design work needs 2 ~ 3 times revisions and confirmation. Thus, we look forward to cooperating with the users who are willing to communicate and work together to build up the best system for them.