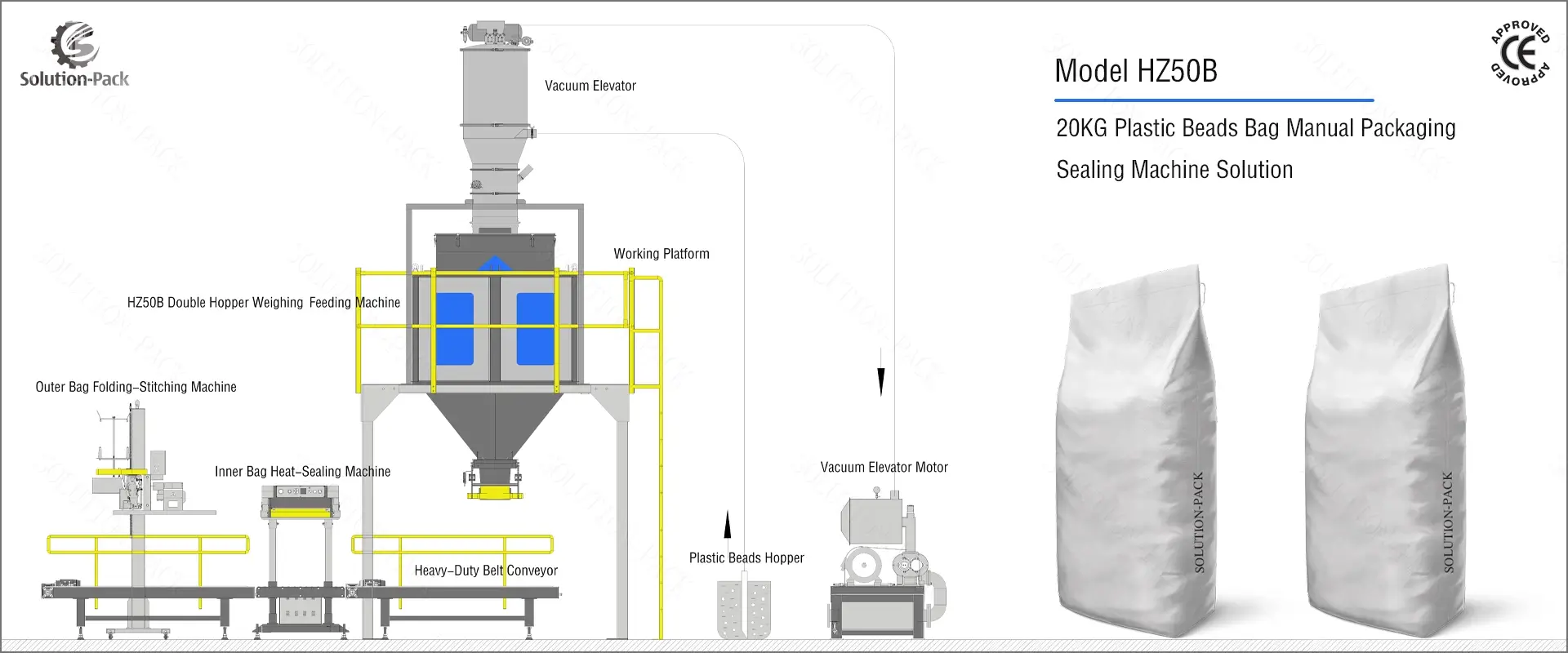

This plastic beads manual bagging sealing machine solution is designed for packaging 20kg plastic beads into PP woven bags with inner PE layers. Generally, the inner PE layer requires a heat-sealing function and the outer PP woven layer needs a folding stitching function. It could support users to package 200 ~ 240 bags per hour with two operators to handle the bag feeding and sealing process. A high-elevating capacity vacuum elevator is equipped and connected to the raw materials hopper to avoid pollution during the elevating process. Meanwhile, all the material contacting parts are made of SUS304 stainless steel and the frame parts are made of strengthened coated carbon steel.

WORKING PROCESS | PLASTIC BEADS MANUAL BAGGING SEALING MACHINE

1.0) Material Elevating: the model VC-10 vacuum elevator adopts a 7.5KW roots blower to create negative pressure. The sucking gun connects to users’ front production line or raw materials hopper with soft tubes. A second-level supporting platform is installed to fix the vacuum elevator and ensure stable running performance. The stainless-steel filter is used to provide a clean elevating environment. This vacuum elevator system could elevate around 5000 ~ 6000 kg/hour to meet the production requirement.

1.1) Material Weighing Filling: model HZ50B automatic weighing system uses a double hopper design. Each hopper has a volume of 36 litres and uses a crude and precise vibrator to feed material and control the weighing accuracy with a Mettler Toledo load cell. The machine frame and contacting parts are made of polished SUS304 stainless steel to provide a clean dosing environment. It could dose 8 ~ 10 times per minute for 20 ~ 50kg uniform granule products. Internationally famous electrical and pneumatic parts are used to ensure stable running performance. The bag clamper system is fully customized to users’ bag sizes.

1.2) Manual Bagging: The plastic beads manual bagging sealing machine solution requires a labourer to prepare the empty PP woven bags and open the bag mouth to feed to the clamper device. When the bag is clamped and ready, the worker only needs to press the hand switch to signal the weighing hopper to release plastic beads into the bags. The bag shall drop on the heavy-duty conveyor after the products are filled. The worker could prepare for the next bags during the plastic beads filling process. The height of the heavy-duty conveyor could be adjusted according to different bag lengths in production.

1.3) Inner PE Bag Heat-Sealing: We have designed a power-free roller conveyor at the heat-sealing position. The worker can take time to make the inner PE layer flat and put it into the sealing bar. The heat-sealing device is controlled by a foot switch to facilitate users within daily operations. The sealing temperature can be adjusted freely according to the thickness of the PE film. The sealing bar width is normally 10mm and the length is customized to the bag width to ensure the best production state.

1.4) Outer Woven Bag Folding Stitching: The operator must insert the sealed PE bag and pull the outer PP woven bag to send it to the folding stitching system’s chain guide. The chain guide could protect the workers in the sealing process. The bag mouth guiding, folding, and stitching systems are integrated as a whole unit with universal wheels. The stitching height could be adjusted according to the exact woven bag sizes. The final stitched bag shall be directly conveyed for manual palletizing or truck loading. This plastic beads manual bagging sealing machine solution suits most start-up factories with limited production capacities.

Choose Solution-Pack | The Best Plastic Beads Manual Bagging Sealing Machine Solution

Solution-Pack provides customized plastic beads manual bagging sealing machine solutions for worldwide users to realize simple and easy production. These solutions could automatically support users in packaging 20 ~ 50kg of plastic beads or similar granule products into PP woven bags with high production capacity. Besides realizing the basic function of packaging, we also provide optional functions like bag-down conveyor systems, weight-checking systems, unqualified bag-rejecting systems, and robot palletizing systems. The entire solution is customized to each user’s production requirements. Solution-Pack provides official CE certification for all equipment.

Most users are concerned about the machine’s installation and after-service. We offer two types of options according to the user’s needs. The first option is on-site installation and training service. It is suitable for users who use automatic packaging machine solutions for the first time and require detailed instructions to support the operators. We shall send engineers to the site to support the installation and training work. The second option is remote online installation and training service. It is suitable for users familiar with the packaging machine equipment and has professional technicians. We will do this work via WhatsApp or WeChat. No matter which option users choose, we shall create an after-service group for users to communicate instantly.