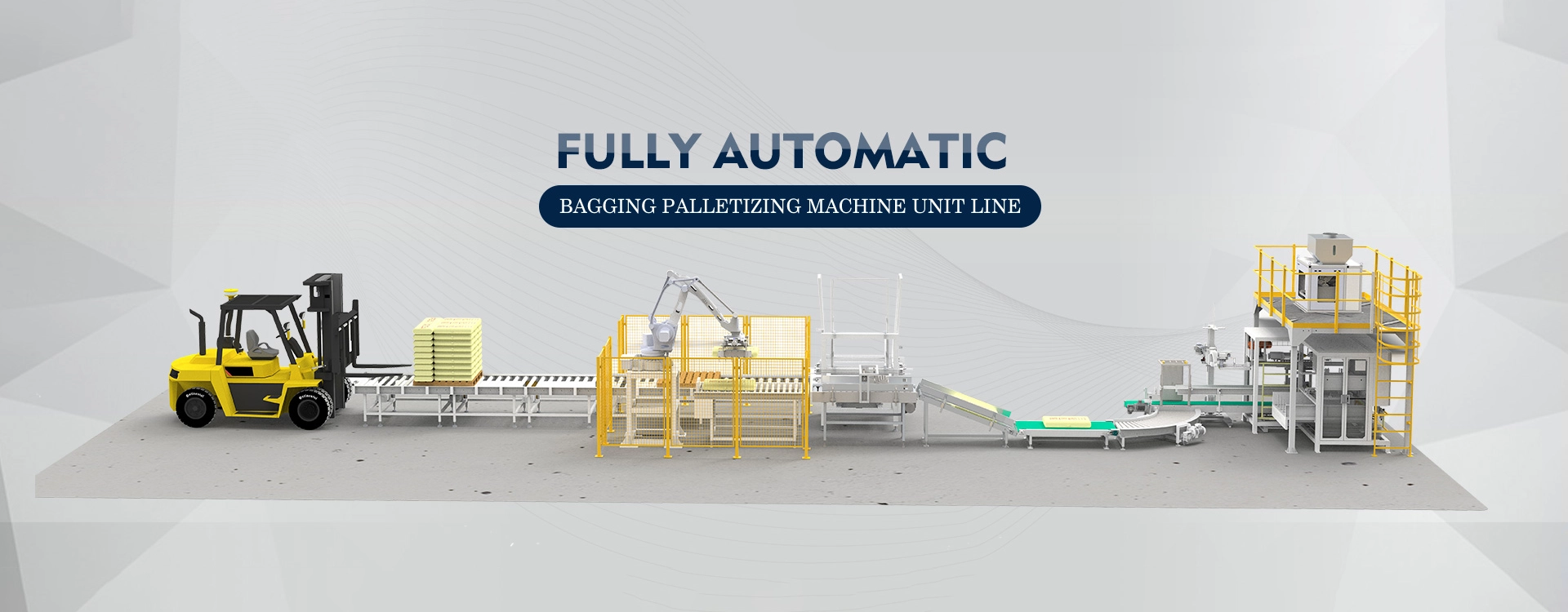

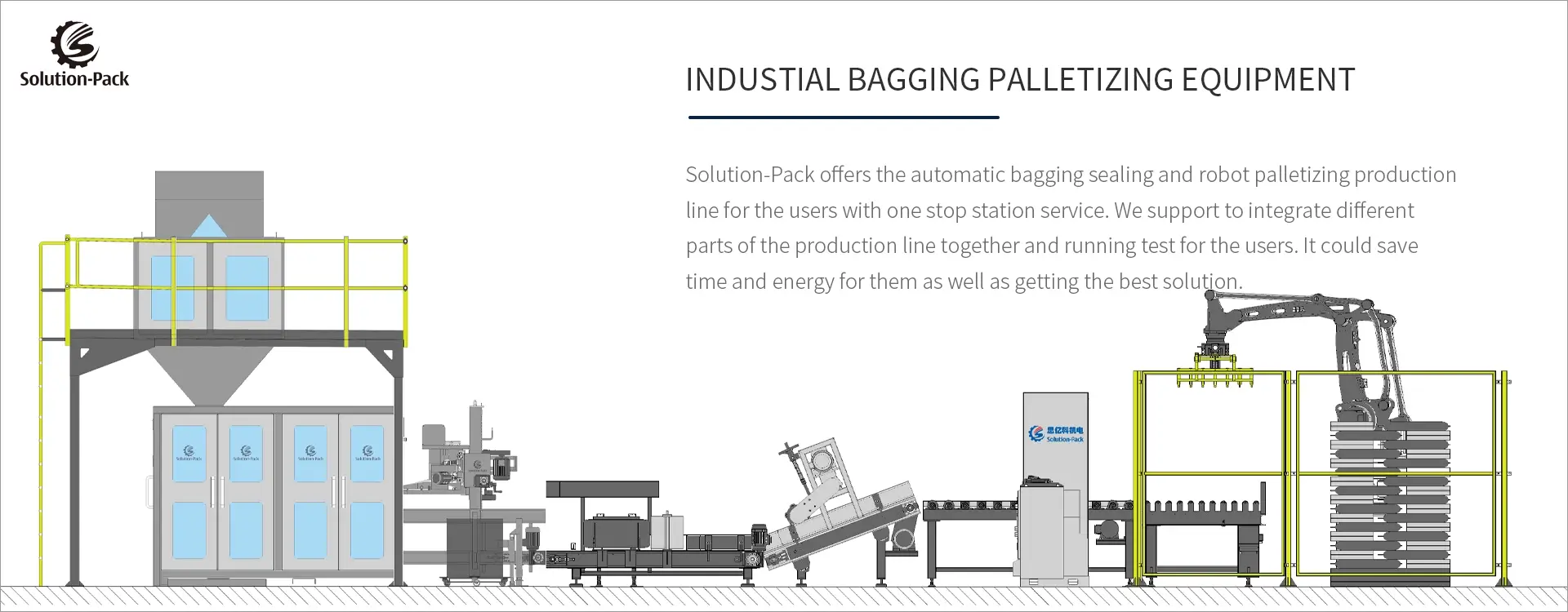

The industrial bagging solutions from Solution-Pack focus on the heavy-duty bag weighing bagging sealing and robot palletizing process. These bagging machine equipment support the users to pack raw materials into 10 ~ 50 kg bags and then palletize them onto the pallet or pack them into the 1000 kg jumbo bags directly for easy transportation and marketing. Both fully automatic and manual bagging palletizing equipment are available for the users according to their required production capacity and packaging material features. These industrial packaging systems are now widely applied in grains, seeds, rice, sugar, animal feed, aqua feed, urea fertilizer, compound fertilizer, wheat flour, and tapioca starch market.

Select Your Industrial Bagging Solutions

TYPICAL INDUSTRIAL BAGGING MACHINE FEATURES

Intelligent Design

The industrial bagging machine equipment adopts a compact structure design pattern to save installation space for the users. The bagging sealing machine frame uses strengthened carbon steel and the material contacting parts all adopt stainless steel. The machine’s surface is fully grey-coated with anti-corrosion features. The safety door system uses a transparent Lexan board that allows the user to check the mechanical movements inside the machine easily.

Advanced Configuration

As a professional heavy-duty bag packing machine manufacturer, we offer high-standard configuration for the users with a pleasant user experience. We adopt the smart Siemens PLC control with a 10-inch colourful HMI interface for convenient operation. A customized language operation interface could be required. The other related pneumatic and electrical parts also adopt AirTac, SMC, Schneider, or equal brands which could be sourced from the local market.

Customized Features

The weighing system could connect with the user’s front production line or raw material silo. The installation layout design shall follow the users’ factory design to save installation space. The bag feeding and sealing system are customized to the users’ woven sacks. Other ancillary equipment like the weight checker, metal detector, inkjet printer, pallet bank, and pallet wrapping machine could also be required. The design document shall be provided to the user before starting the project.

GUIDANCE ON SELECTING THE BAGGING PALLETIZING EQUIPMENT

The bagging palletizing equipment is classified into two groups: automatic and manual type. Some clients may meet the issue of selecting the machine models. The first point we need to consider is the target production capacity. The manual bagging machine is the best choice if the users only need to produce 300 ~ 400 bags per hour. The automatic bagging palletizing machine is the best choice if the users need to produce 600 bags per hour. However, the users could also use two manual bagging machine units to meet the production capacity if the local labour cost is acceptable.

The second point is to check the quality of the bags. The automatic type machines require the bag to be vacuum-suckable. The PP woven sacks in some markets are of low quality without PE coats inside or outside the bags. The manual bagging machine is the best choice if the users’ sacks don’t have a coat layer and the automatic bagging machine is applicable if the users’ sacks have a coat layer. We shall study the users’ requirements and propose the most suitable solution for their reference.

CHOOSE SOLUTION-PACK | FIND THE BEST INDUSTRIAL PACKAGING PRODUCTION LINE

- We are one of the leading industrial packaging machine manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. We support the integration of different parts of the bagging palletizing production line for the users. The installation solution design is fully customized to the client’s factory layout. Welcome to contact us to get professional guidance on the bagging palletizing project.

- We provide two types of after-sale service systems for the client under different conditions. We propose the online instructing installation service if the user has a professional engineering team. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. We shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user if the user is for the first time installing the machine and without any knowledge of packaging machines. It depends on the user’s choice to conduct the work.