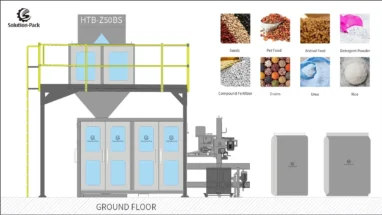

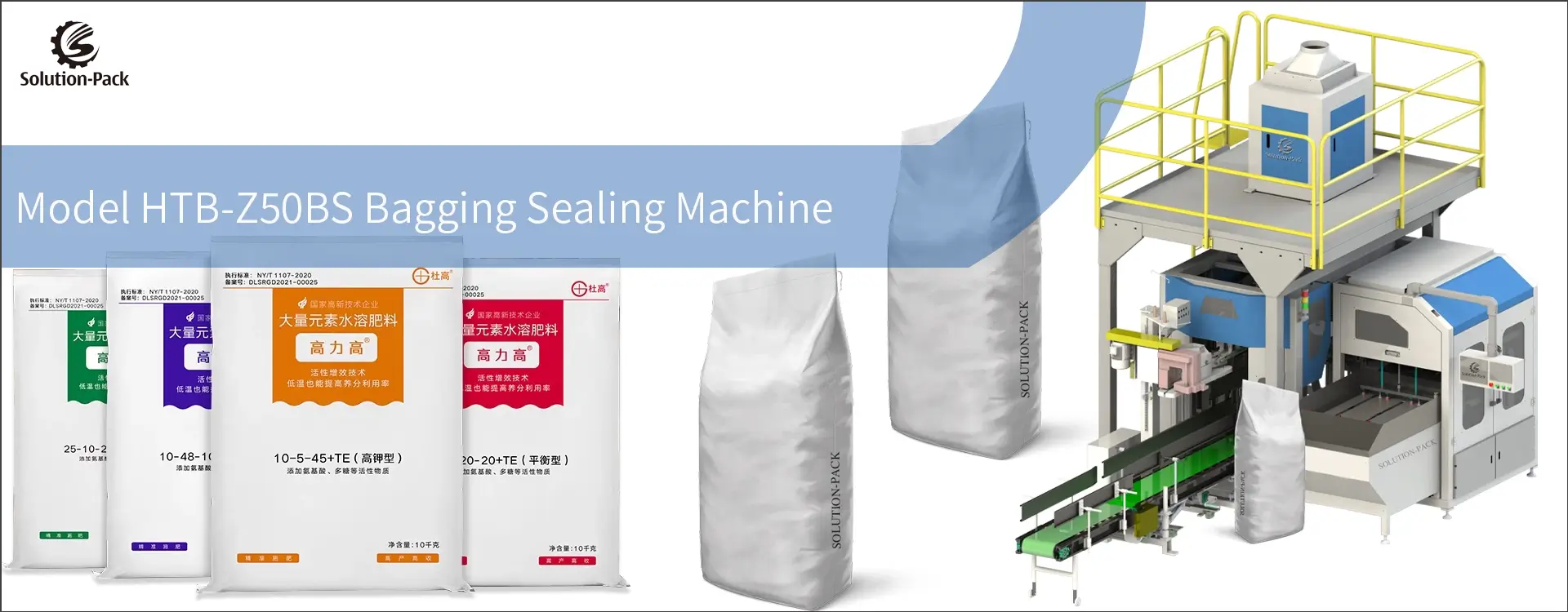

Model HTB-Z50BS automatic bagging sealing machine unit is a heavy-duty bag packaging system for M-type woven bags. It shall realize the function of automatic bag feeding, material dosing, bag mouth opening, material feeding, bag mouth sealing, and final bag conveying. The process runs automatically and only requires one manual to prepare the pp woven bags into the bag magazine. It could support the user to produce around 600 bags per hour with stable performance. This weighing bagging system is now widely applied to grains, seeds, fertilizer, animal feed, aqua feed, chemical granules, and plastic granules market to improve production efficiency and save labour costs.

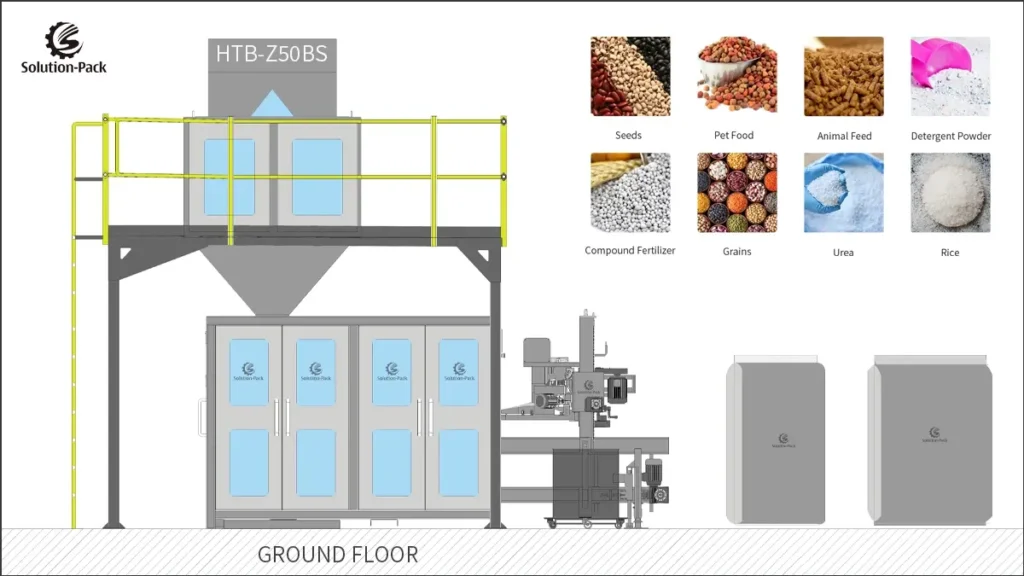

MODEL HTB-Z50BS TECHNICAL DATA

This automatic bagging sealing machine unit is suitable for industrial factories to package 20 – 50 kg granule products into pre-made M-type PP woven bags with PE covers coated inside or outside. It could connect with the front raw material processing line for continuous production. The production only requires one labourer to feed the empty bags into the bag magazine and the bag bank could store around 200 bags per time. There are different options for sealing systems according to the production requirement.

SUBMIT HERE TO CONTACT US

TYPICAL FEATURES OF THE AUTOMATIC BAGGING SEALING MACHINE

This automatic weighing and bagging machine consists of the double hopper weighing filling system and the bagging system with a maintenance working platform. It is designed to pack 20 ~ 50 kg granule products into the flat PP Woven Bag and then sew the bag mouth automatically. The bag magazine, bag feeding system, and bag clamping system adopt an integrated design style to save installation space for the user. The platform could be removed if the user has the second floor for installing the weighing system directly.

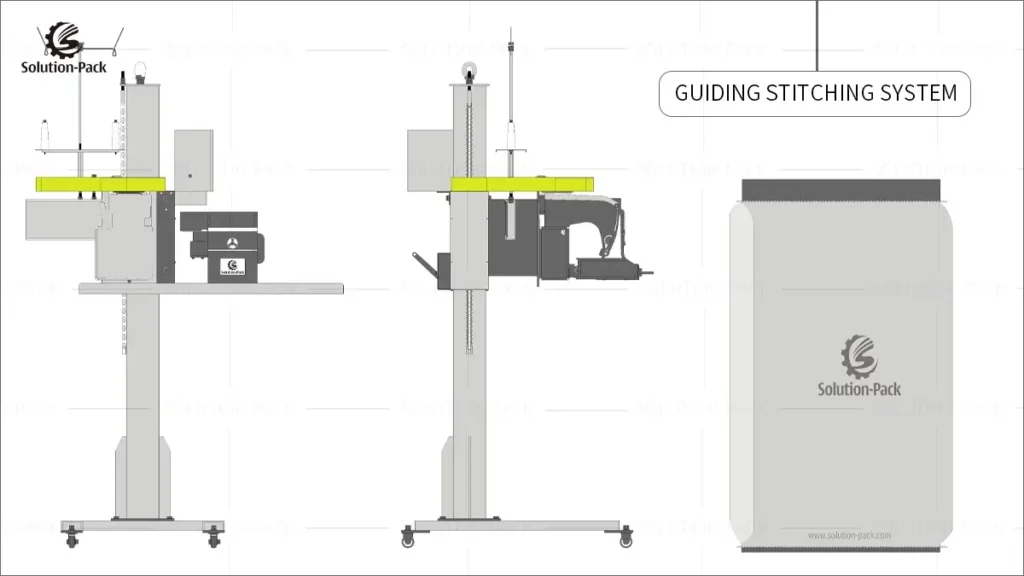

The weighing bagging machine unit uses Siemens PLC & HMI for control and display with a standard CH/EN double language human-friendly interface. The other electrical and pneumatic parts all adopt internationally famous brands like SMC Cylinder, SMC Solenoid Valve, Becker Vacuum Pump, Schneider Relay, Schneider Servo Motor, etc. The sewing system is Newlong Brand and the user could also require the target brand. The standard machine unit shall adopt the stainless steel frame for the material contacting part and coated carbon steel frame with better strength.

This machine unit adopts the vacuum sucker system to feed the M-type pp woven sack to the bag clamp system. Thus, it requires the pp woven sack to be vacuum-suckable. Normally, we require the bag to have a PE-coated layer inside or outside the bag. It could also be an independent layer inside the bag, but the bag mouth part should be pre-stitched. Meanwhile, the HTB-Z50BS machine model is designed for M-type woven bag packaging.

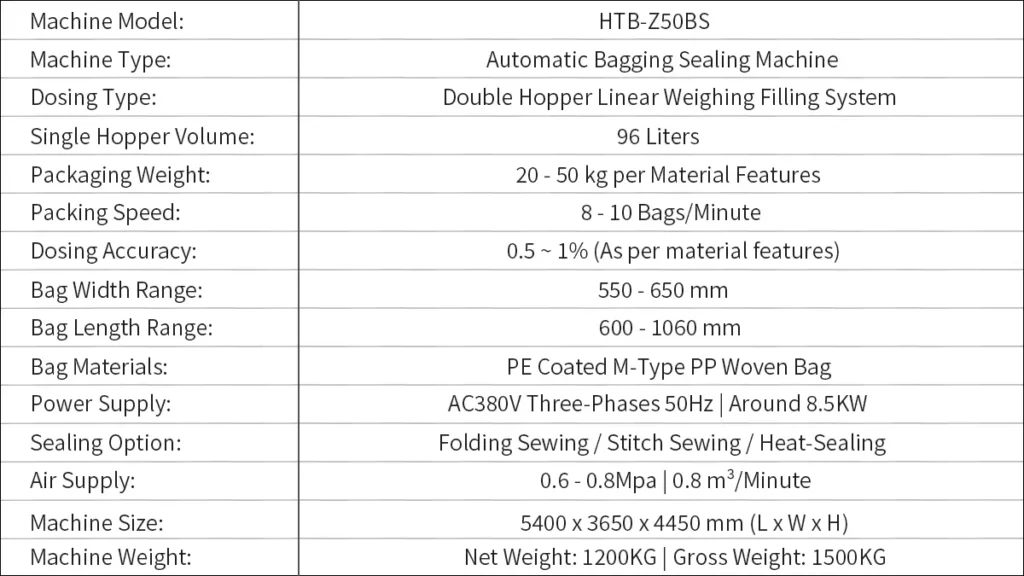

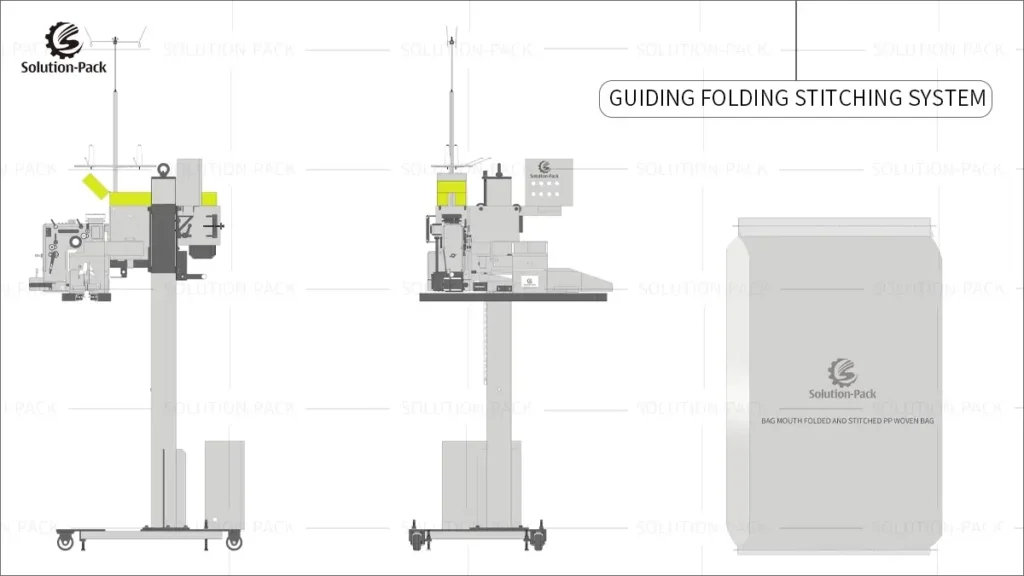

OPTIONAL WEIGHING BAGGING MACHINE SOLUTION SEALING SYSTEMS

CHOOSE SOLUTION-PACK | FIND THE BEST AUTOMATIC BAGGING STITCHING MACHINE SOLUTION

- We are one of the leading industrial bagging and palletizing solution manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. The HTB-Z50BS model is one of the mature packaging machines in our equipment series. It has supported many factories to improve production capacity effectively. You will surely get the most suitable machine solution for your project if you cooperate with us.

- We provide two types of after-sale service systems for the client under different conditions. We propose the online instructing installation service if the user has a professional engineering team. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, suppose the user is for the first time to install the machine and without any knowledge of packaging machines. In that case, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.