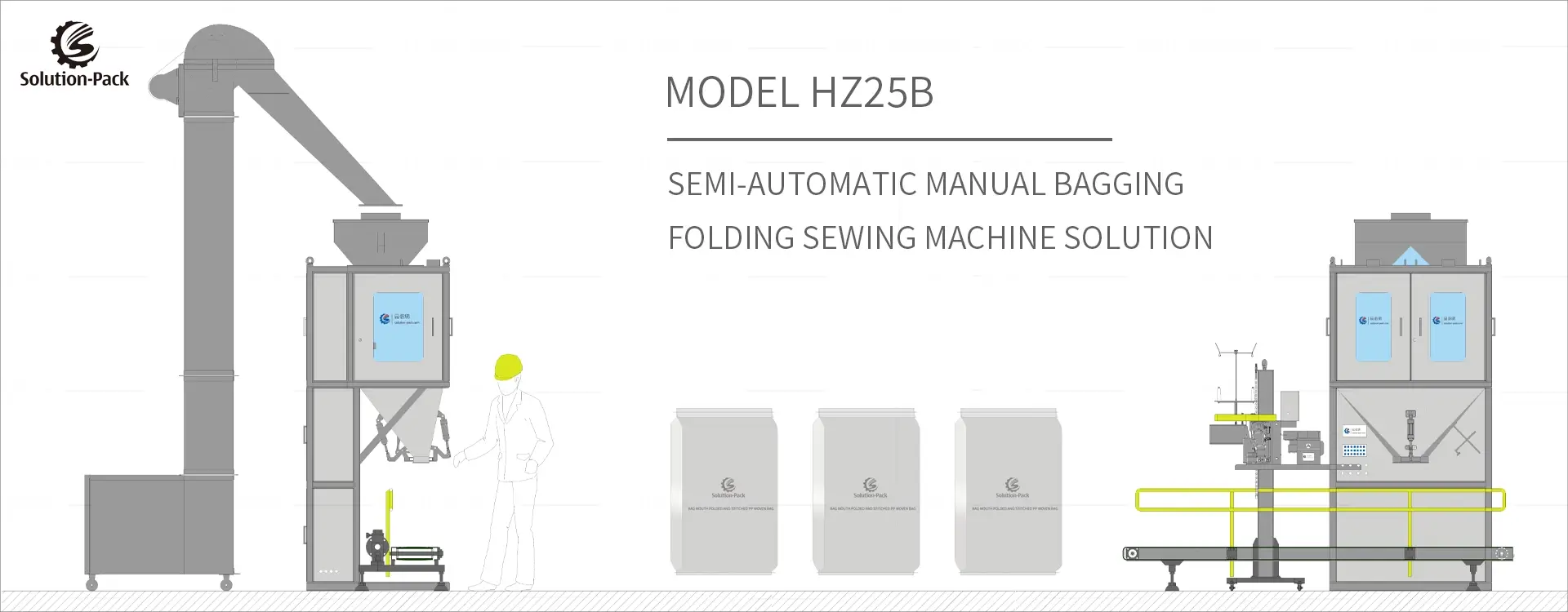

The model HZ25B manual bagging sealing machine is a semi-automatic packaging solution. It adopts the double-hopper design with a crude and fine vibration feeding system to weigh the granule products with the Mettler Toledo load cell. The users could choose the hand-switch or foot-switch to control the material filling process manually and easily. Each hopper has a volume of 49 Liters and can dose 10 – 25 kg products per material bulk density features. The sealing system could choose the continuous heat sealer or the stitch sewer depending on the bag material that the clients use. This manual bagging sewing system is widely applied in packaging uniform granule products like rice, beans, seeds, detergent powder, plastic granules, grains, chemical fertilizers, animal feed, pet food, etc. with stable running performance.

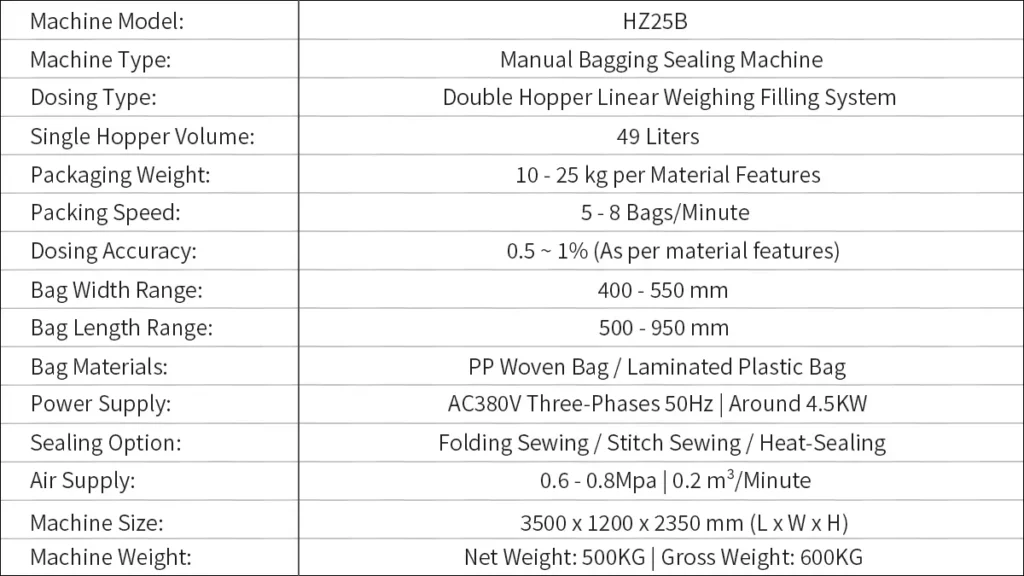

MODEL HZ25B TECHNICAL DATA

This manual bagging sealing machine unit is suitable for start-up factories or home businesses to package 10 – 25 kg granule products into the pre-made plastic of pp woven bags. It could connect a bucket elevator system with a material-level sensor to realize continuous production. The production only requires one labourer to feed the empty bags and arrange the bag mouth into the sealing system directly after the material filling process finishes. There are different options for sealing systems according to the production requirement.

SUBMIT HERE TO CONTACT US

TYPICAL FEATURES OF THE MANUAL BAGGING SEALING MACHINE

This manual bagging solution is a basic semi-automatic packaging solution. The material contacting parts adopt the food-level stainless steel and the machine frame parts adopt the coated carbon steel with great strength. The conveyor system adopts a heavy-duty design with a PVC green belt to hold heavy weight. The operation panel uses the standard typical General Measure Instrument panel with simple buttons for easy operation. The Mettler Toledo load cells are equipped to ensure weighing accuracy.

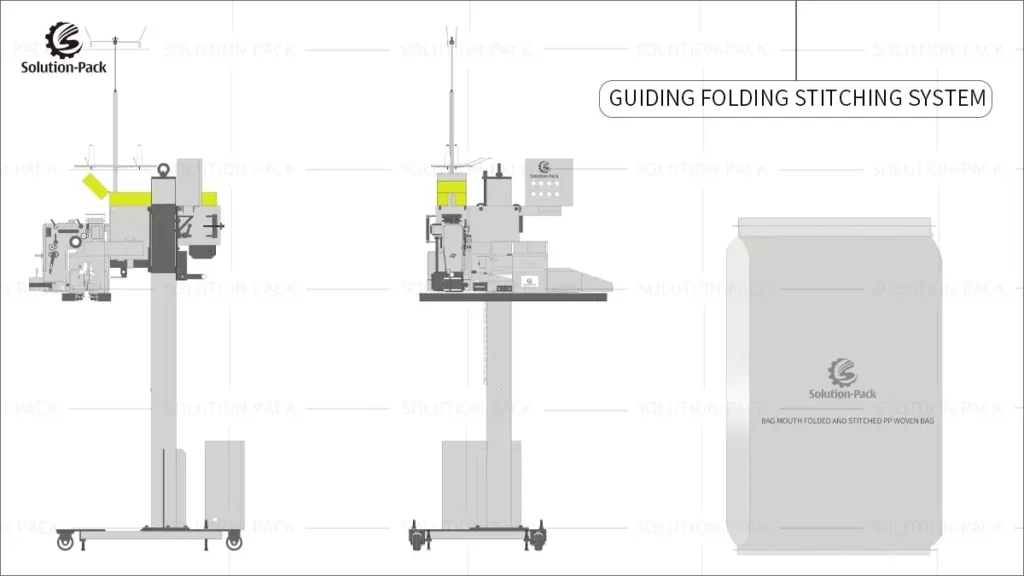

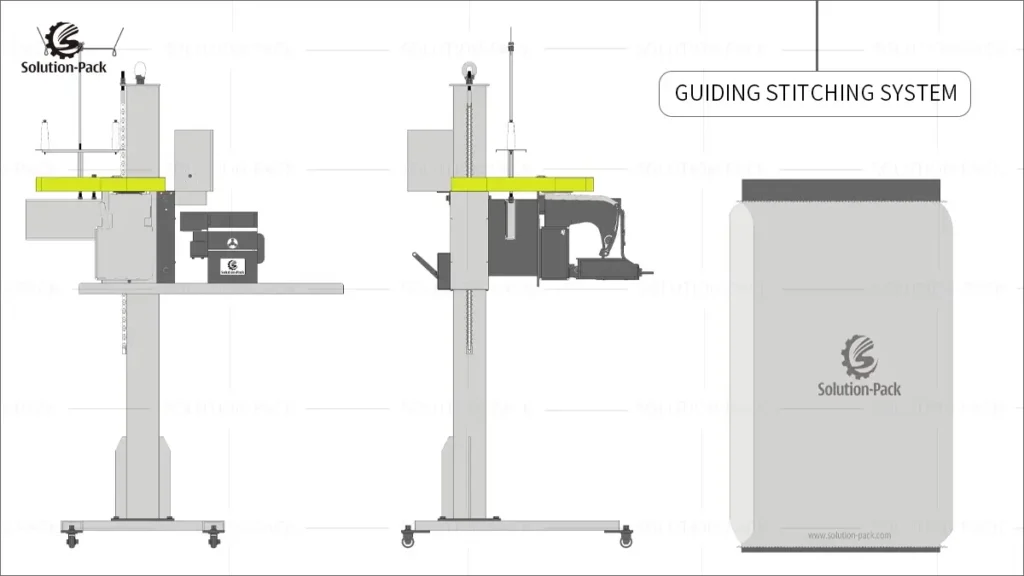

To better support the users to improve production efficiency and ensure operation safety, Solution-Pack has self-designed the bag mouth guiding system to help the workers deliver the bag mouth to the sealing system easily and smoothly. The guiding speed shall be synchronized with the below conveyor speed to ensure the best sealing performance. The material feeding mouth size could be customized per users’ exact bag sizes. The hand-switch or foot-switch could allow the operator to control the filling process freely.

This semi-automatic bagging machine solution could follow the users’ requirement to connect with the bag pushing down conveyor, weight checking system, metal detecting system, unqualified products rejecting system, bag flatten conveyor, label attaching system, robot palletizing system, or the robot carton boxing system to form an integrated production line. Generally, we could combine 2 or 3 manual bagging systems with one secondary packaging line to save space and improve the production capacity for the users.

OPTIONAL MANUAL BAGGING SOLUTION SEALING SYSTEMS

CHOOSE SOLUTION-PACK | FIND THE BEST SEMI-AUTOMATIC BAGGING MACHINE SOLUTION

- We are one of the leading industrial bagging and palletizing solution manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. The HZ5B model is one of the mature packaging machines in our equipment. It has supported many factories to improve production capacity effectively. You will surely get the most suitable machine solution for your project if you cooperate with us.

- We provide two types of after-sale service systems for the client under different conditions. We propose the online instructing installation service if the user has a professional engineering team. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, suppose the user is for the first time to install the machine and without any knowledge of packaging machines. In that case, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.