The model ML-Y3 multi-track liquid sachet packing machine unit is designed for packaging liquid or semi-liquid products into the 3-side seal sachets automatically. It adopts an advanced design and could connect with the rotary pump elevator or gear pump elevator to realize the material elevating process. The standard machine unit shall realize the function of liquid dosing, film pulling, date printing, film splitting, material filling, heat-sealing, and finished product output. This liquid sachet packaging machine solution is widely applied in liquid and semi-liquid markets like ketchup sauce, tomato sauce, chilli sauce, hair wash, mouthwash, shampoo, oil, water, health care, daily care products, etc.

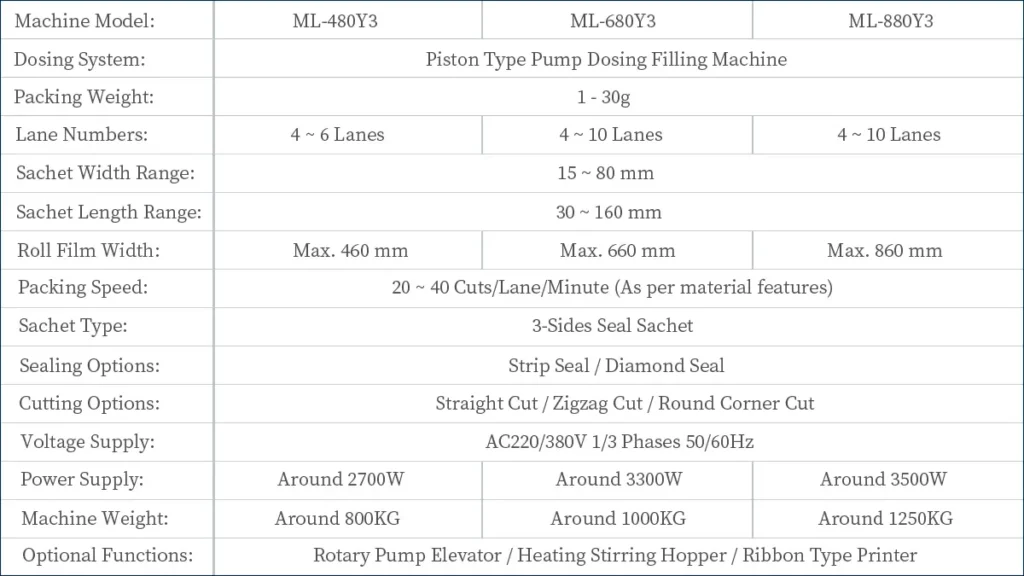

TECHNICAL DATA | ML-Y3 LIQUID SACHET PACKING MACHINE

This 3-side seal sachet packaging machine solution is fully customized to the client’s requirements. It could design a maximum of 10 lanes for production and each lane could perform a stable running speed of 25 – 40 cuts per minute as per sachet patterns and material features. There are different kinds of sealing and cutting patterns for options: straight cut, zigzag cut, round corner cut, connected cut, strip seal, and diamond seal. Each filling tunnel shall adopt the volumetric cup doser independently with high measuring accuracy. This multi-track liquid packaging machine could support the users to improve production efficiency and save labour costs effectively with stable performance.

SUBMIT HERE TO CONTACT US

KEY FEATURES OF THE MULTI-TRACK LIQUID PACKAGING MACHINE

This solution adopts the multi-lane design style which could perform the packaging speed of around 30 ~ 40 cuts per lane per minute according to the material features and packing weight. It could support the users to improve the production capacity effectively and save labour costs. The machine’s hopper could connect with the user’s front production line storing tank to realize continuous packaging and facilitate the cleaning process after production. The finished product output part could customize the counting and grouping device to support the users to repack the sachets into big bags or boxes.

The liquid sachet packing machine adopts a high-standard configuration to meet international market needs. Intelligent Germany Siemens PLC and HMI Interface are used for better operation experience. The other pneumatic and electrical parts also adopt internationally famous brands like SMC, IBC, OMRON, SCHNEIDER, AIRTAC, etc. It could ensure the stable performance of the machine and also facilitate the user to source spare parts from the local market easily. The whole machine frame and the material contacting parts use food-level stainless steel and the safety door adopts the Lexan board with high transparency for checking the mechanical movements.

According to the features of the liquid products, the double jacket constant temperature hopper could be customized, and the hopper volume is decided by the target production capacity. It is mostly used in honey and ketchup product packaging when the user does not have a front processing line for connection. The pump elevating system needs to consider the packaging products before decision. The food products shall use the rotary-type pump which ensures contacting surface food level steel. The chemical products normally propose the gear pump which has anti-corrosion features.

WHY CHOOSE THE LIQUID SACHET PACKAGING MACHINE FOR PRODUCTION?

Six reasons affect the choice of liquid sachet packaging machines. First, the multi-track liquid sachet packaging machine could produce beautiful and neat sachets for the users which could better meet the international market’s requirements. Second, it adopts the advanced weighing filling system to dose the liquid products with high accuracy which could save production waste. Third, the whole packaging process only requires one labourer to operate and maintain the machine which avoids the pollution from workers’ participation.

Fourth, the sachet packing machine could support the users to produce more than 200 sachets per minute to improve the production capacity effectively and automatically. Fifth, the packaging machine could be customized to produce different kinds of sachet patterns according to the users’ requirements. Sixth, the sachet packaging equipment could connect with the front raw material production line and the following repackaging line to form the whole production process line.

CHOOSE SOLUTION-PACK | FIND THE BEST STICK & SACHET PACKAGING MACHINE SOLUTION

- We are one of the leading stick & sachet packing machine manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. No matter if the users need a single machine unit, or if they need the whole packaging production line, we shall provide professional service for them to know about the machine and work together with them to clarify all the details before reaching an agreement. Our solutions have been widely adopted in different areas of the market with stable performance and great feedback.

- We provide two types of after-sale service systems for the client under different conditions. If the user has a professional engineering team, we propose the online instructing installation service. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, if the user is for the first time to install the machine and without any knowledge of packaging machines, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.