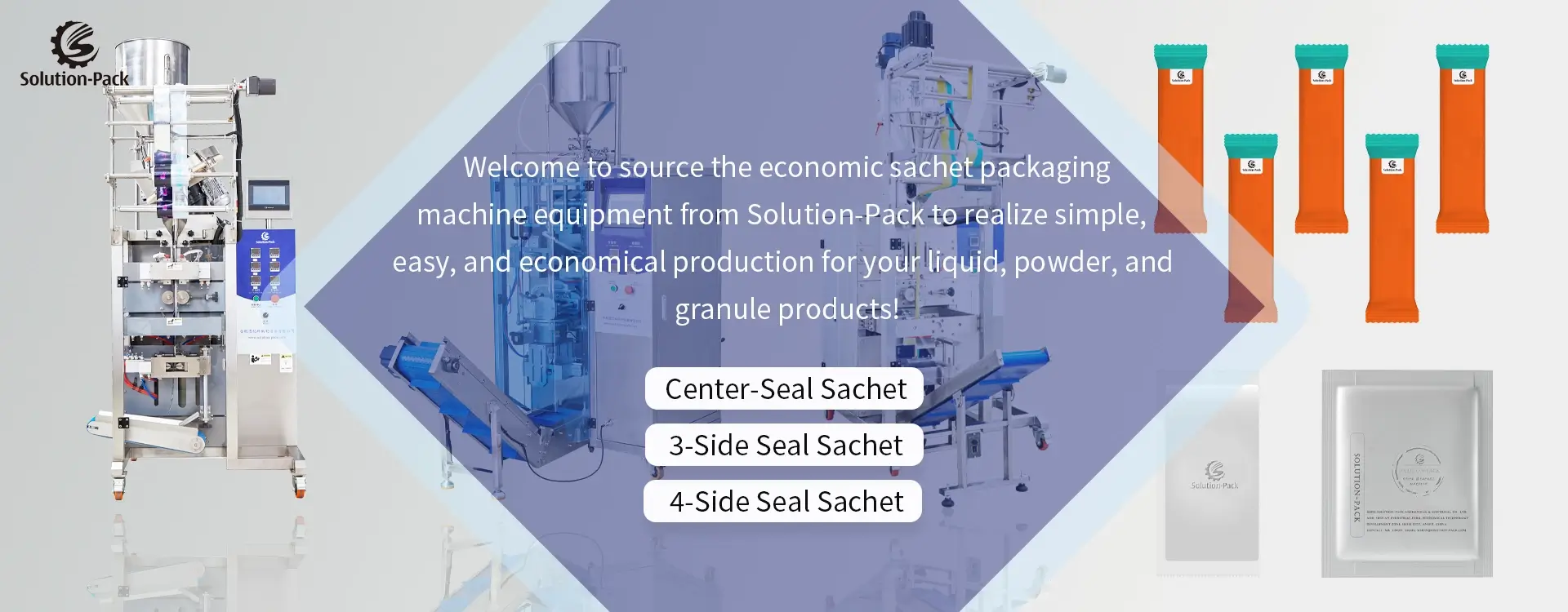

Solution-Pack offers different types of small sachet packaging machine equipment for powder, granule, and liquid products. These machines could produce the center-seal stick sachets, the 3-side seal sachets, and the 4-side seal sachets as per clients’ production requirements. The sachet packing machines are easy to operate and simple to maintain with a human-friendly double language HMI interface. They are the best choices for start-up factories, laboratories, and home businesses with economic budget costs. They are widely applied in food, additives, chemicals, daily care, medicine, cosmetics, instant drinks, etc. markets with stable running performance.

ADVANCED SACHET PACKAGING MACHINE FEATURES

Easy Production

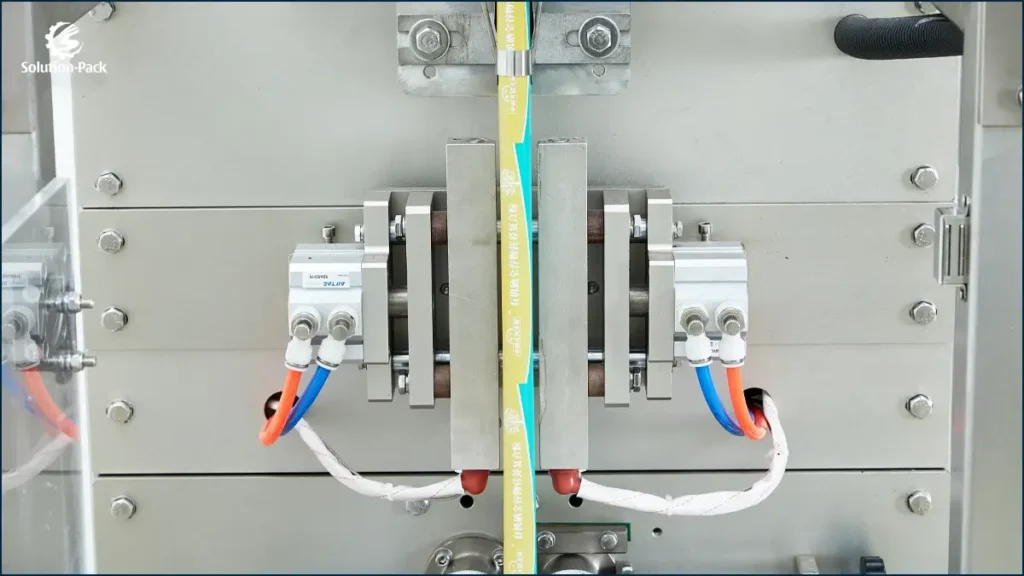

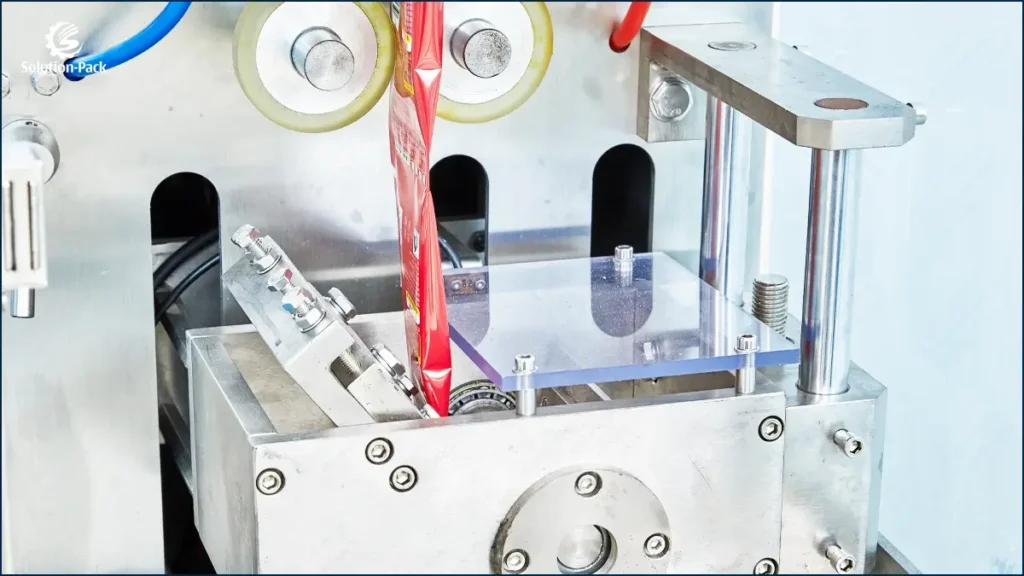

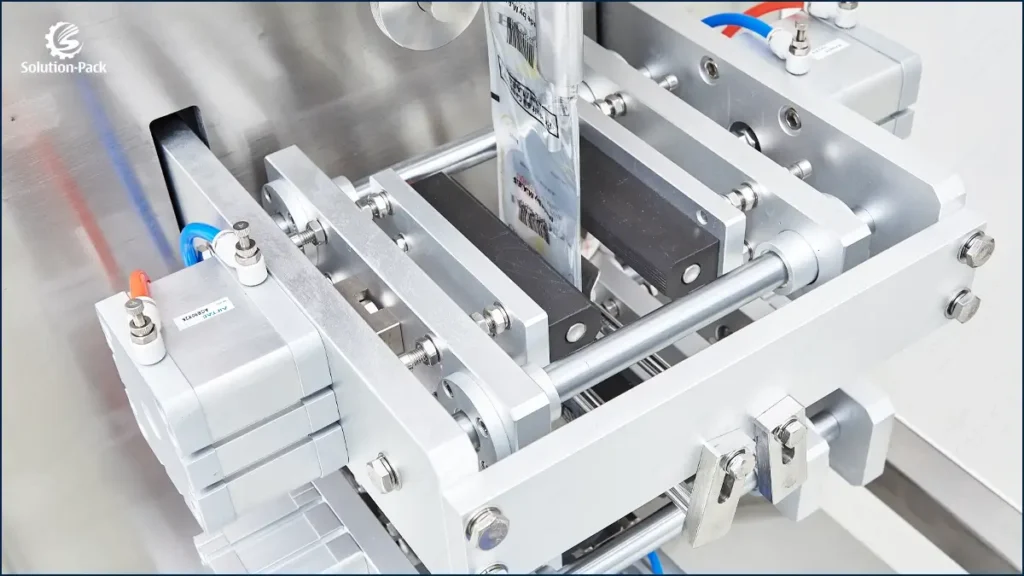

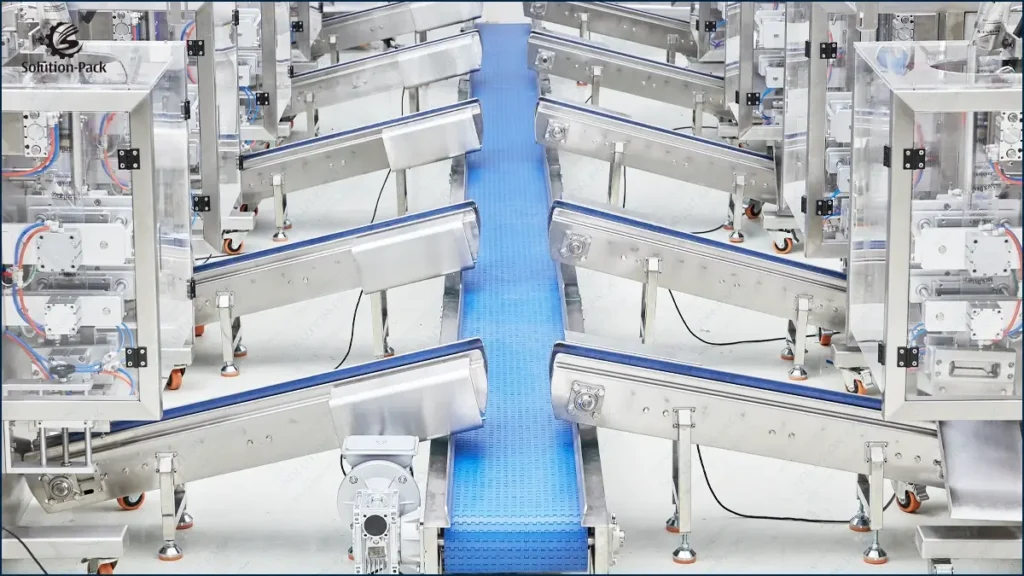

The small sachets are difficult to adopt the manual packaging method due to their small sizes and filling volumes. The sachet packing equipment could support the users in realizing the automatic packaging process easily. It could perform the function of material dosing, film pulling, date printing, material filling, sachet forming, material filling, heat-sealing, cutting, and finished sachet output. The cutting and sealing patterns could also be customized as per production needs. The single-machine unit only requires one laborer to operate and perform a stable running speed of not less than 30 sachets per minute. By connecting with different kinds of dosing and elevating systems, it could package different kinds of materials with stable performance.

Economic Budget

The sachet machines are mainly designed for start-up factories with low-cost investment compared with the high-speed multi-lane sachet packaging equipment. The whole machine frame and the material contacting parts are all made of food-level steel. All the machine models adopt the Mitsubishi PLC control with an intelligent HMI interface for easy operation. The small sachet packing equipment barely needs to change the spare parts in daily production which saves costs for the users in the maintenance. The main machine generally integrates with the dosing system together and does not tear down when shipping the goods abroad which allows the users to charge electricity to run directly when the machine arrives at the factory.

Guidance on Selecting the Suitable Sachet Packing Machine Models

When selecting the sachet machine for production, the clients need to provide clear what kinds of material they need to pack exactly. Different kinds of materials need to use suitable dosing and elevating systems for production. If the material is liquid, we could choose from the Y-100 machine series; if the material is granule, we could choose from the K-100 machine series; if the material is powder, then we could choose from the F-100 machine series. Each machine model has their unique features with related functions. Solution-Pack shall collect the clients’ specific requirements first and analyze them before proposing the correct machine model for their projects.

When the packaging material is confirmed okay, we need to clarify the sachet patterns that the clients need to produce. Each machine model is uniquely designed to produce center-seal sachets, 3-side seal sachets, or 4-side seal sachets. The sealing patterns have “Strip Seal” and “Diamond Seal” as options, and the cutting patterns have “Flat Cut”, “Zigzag Cut”, and “Chain Sachets Cut” as options. The sachet-forming collar devices shall be fully customized to the clients’ sachet sizes and shapes. The ribbon-type date printer shall be equipped as standard and the easy tear notch function could be required also. The automatic elevator system shall be proposed according to the packaging material features.

WHY CHOOSE THE SMALL SACHET MACHINE FOR PRODUCTION

Generally speaking, unlike the big bag packaging which could also use the laborer to do the work, it is not realistic to use the manual to pack the small sachet. The sachet is small with limited volume inside to hold materials and most of the sachets in the market display different sealing and cutting styles like flat seal, strip seal, ZigZag Cut, flat cut, chain sachet, easy tear notch, etc. which could not be performed by the laborers easily. Meanwhile, it shall take a lot of time for the manual to make a sachet and fill the material inside accurately. However, an economical small sachet packing equipment could conduct this work easily and produce at least 30 sachets for the users with stable performance and high accuracy. And it could be working continuously with only one laborer to operate and maintain it easily. Thus, to choose the liquid sachet packing equipment for production is the best choice.

CHOOSE SOLUTION-PACK | FIND THE BEST SACHET PACKAGING EQUIPMENT

- We are one of the leading stick and sachet packing equipment manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. The sachet machine supplied by us could support the users to pack different kinds of material into the small sachet with a stable running speed of around 30 – 50 sachets per minute. The whole machine unit adopts the integrated design style to facilitate the users with simple installation and operation. The users could also deliver sample materials to us to do the machine testing work before the order.

- We provide two types of after-sale service systems for the client under different conditions. If the user has a professional engineering team, we propose the online instructing installation service. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, if the user is for the first time to install the machine and without any knowledge of packaging machines, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.