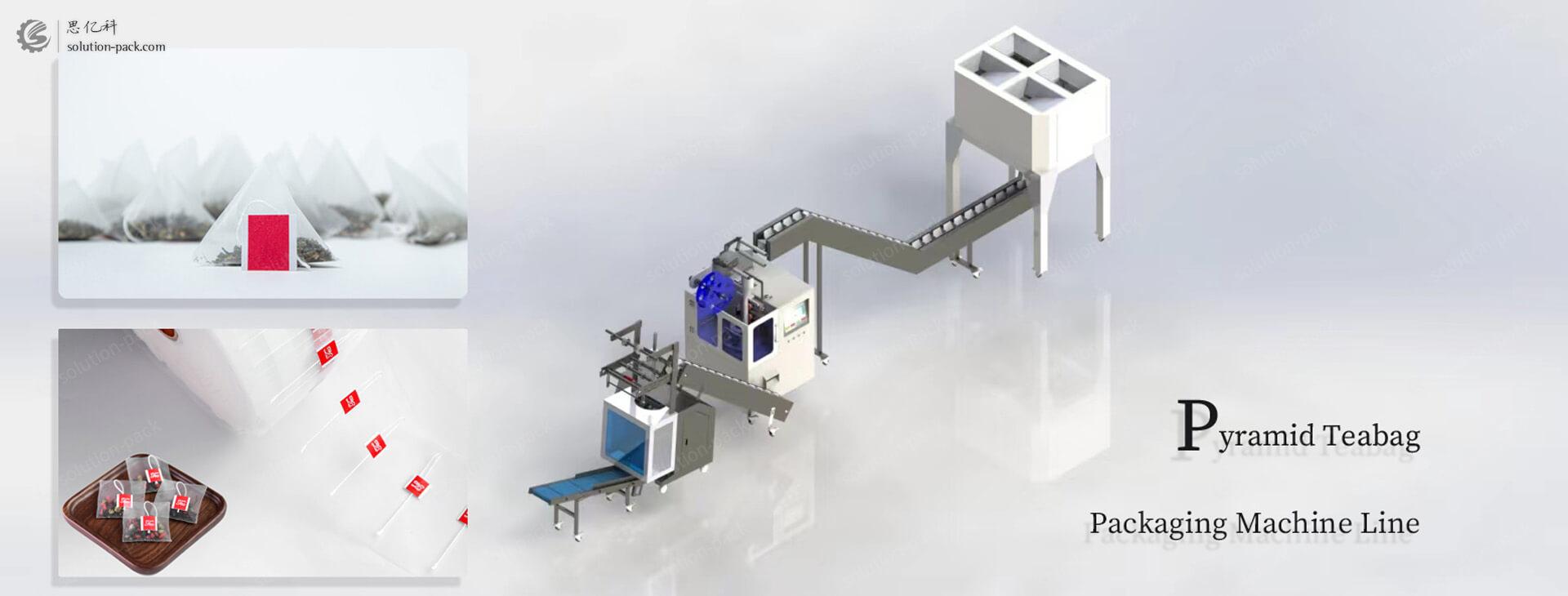

Brief Introduction | Pyramid Tea Bag Packing Machine

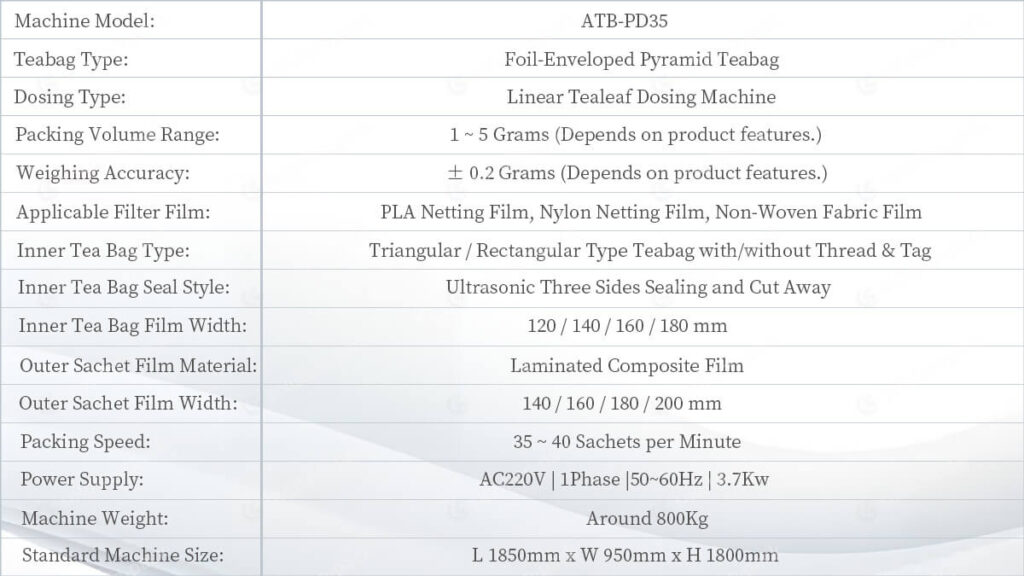

The model ATB-PD35 Automatic Pyramid Tea Bag Packing Machine Unit is a standard mature machine model. This triangular teabag packing machine adopts a separate design style with a linear weighing filling system, pyramid teabag packing machine system, connection bucket conveyor system, and outer sachet packaging system. It could automatically dose the tea leaves products, fill them into the formed pyramid tea bag, and then wrap them into the foil outer sachet. Generally, it could be applied to packing herbal tea, granule tea, healthy tea, pharmacy tea, ground coffee, flower tea, and other fruit tea products.

TYPICAL FEATURES OF THE PYRAMID TEABAG PACKAGING SOLUTION

The ATB-PD35 pyramid tea bag machine unit could perform either triangular-type teabag or rectangular-type teabag, and it just requires a single bond to change the teabag style on the HMI. The linear electronic scale metering could be collocated according to the material. This triangular teabag packing machine could be applied to pack single tea leaf products, and it could also be customized to pack formula-mixed tea products. By adopting the 8-head dosing system, it could mix a maximum of eight kinds of tea products together.

This rectangular teabag packing machine adopts Germany Siemens PLC control with Siemens HMI display for easy and stable operation. The operation language shall be Chinese and English double language and the customized language operation interface needs the client’s support to help with translation. Solution-Pack shall test the machine with the client’s material and then pre-set all the technical data into the system. In this way, we could better ensure the client runs the machine directly when received.

The whole machine frame and material contacting parts shall adopt food-level standard stainless steel to meet CE and GMP requirements. The weighing system could be installed with a platform to put on top of the machine or installed on the floor directly with an elevator system. Both solutions are applicable for production and just need to meet each client’s factory space well. The Z-type bucket elevator system could be required to realize the automatic elevating process.

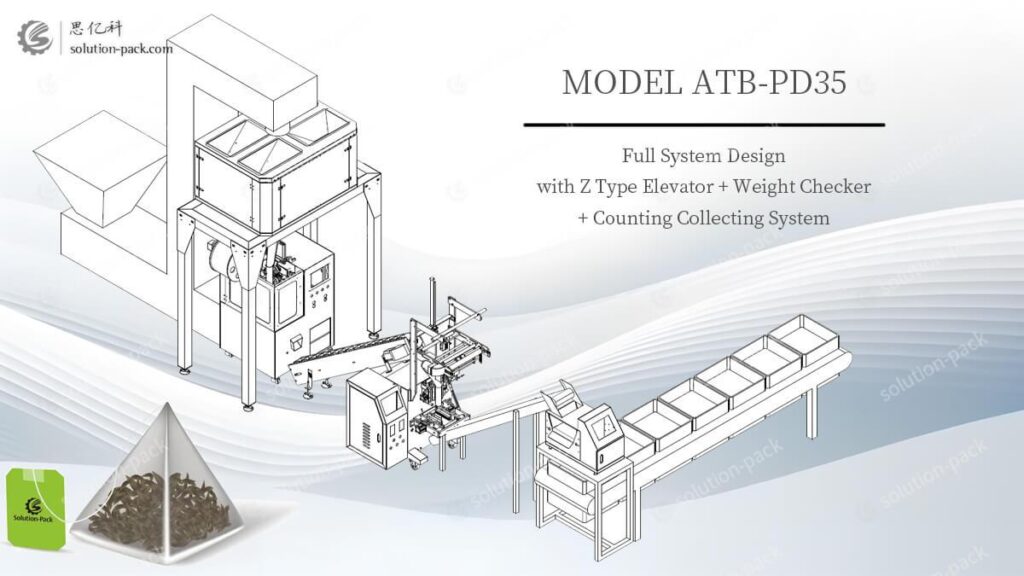

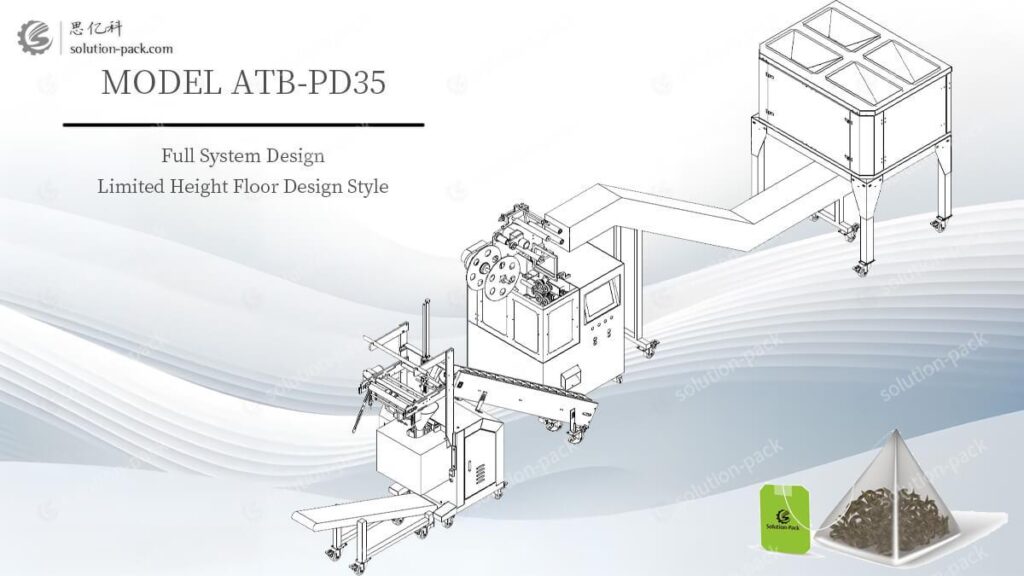

Optional Pyramid Teabag Packaging Solution Line Layout Design

This first pyramid tea bag packing machine design is suitable for the factory which has an installation height of 5 meters. The Z-Type elevator system could support the user to elevate the material automatically. The second tea bag packing machine design is suitable for a factory that has a limited installation height of 3 meters. The height of the machine shall not exceed 2 meters and the manual could feed material directly on the floor.

Choose Solution-Pack, Get Easy & Smart Pyramid Tea Bag Packing Machine Solution

It is well-known that the pyramid teabag is a well-shaped tea bag with a good appearance and is more favorable to the market. Traditional tea bags adopt filter paper film which is soft and only applicable for granule or powder-type tea products. However, the pyramid teabag has a bigger volume and could support the clients to pack more tea leaves into it. Getting a suitable pyramid teabag packing machine for production becomes more and more important. Solution-Pack has focused on the teabag packing machine market for over 12 years with rich experience. We only propose the most suitable packaging solution to meet the client’s production needs.

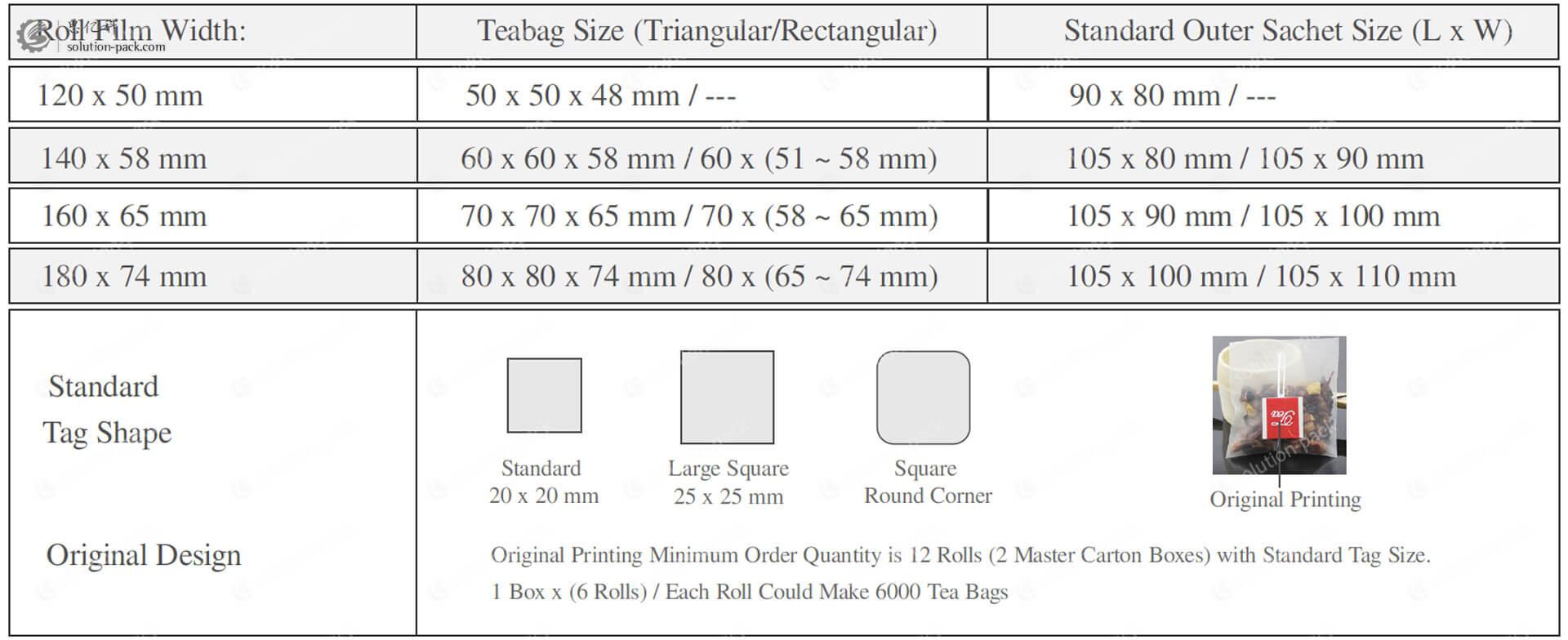

We supply sample material testing services for the client who is a start-up on the tea bag machine project. Each client could deliver around 2KG sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange the machine to test the material and propose the most suitable inner and outer tea bag size for the client. In this way, it could better ensure the client gets the most accurate packaging data for their products. Solution-Pack could also supply the client with customized packaging materials like PLA/Nylon/ Non-Woven Fabric Netting Films.