The VSP630P automatic powder vertical packaging machine solution is a VFFS packaging machine for packing non-free flow powder products. This solution is generally composed of the screw elevator system, auger screw dosing filling system, the vertical form fill seal machine, and the product’s output conveyor. It normally packs a fixed weight from 500 grams to 2000 grams and needs to change the filling tube and screw if the user’s packing weight differs a lot. This vertical powder packing machine could produce a pillow-type bag or a gusset-type bag with different devices equipped. This solution is applicable for 50 ~ 80 meshes of non-free flow powder materials like wheat flour, rice flour, corn flour, bean flour, spices, additives, etc.

TYPICAL FEATURES OF VERTICAL POWDER PACKING MACHINE

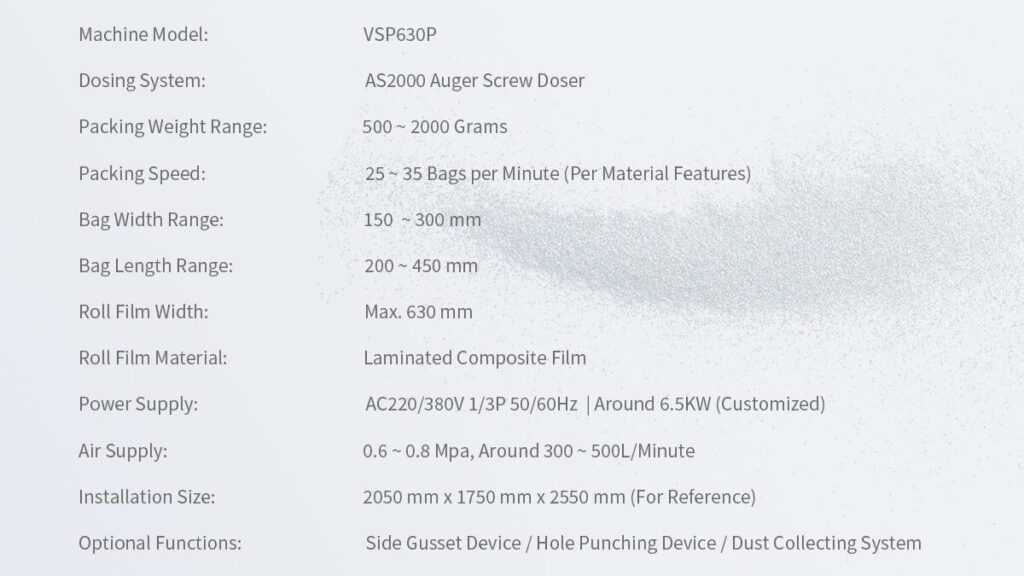

This powder vertical packing machine solution could realize the function of automatic powder elevating, powder dosing, film pulling, date printing, bag forming, powder filling, heat sealing, and finished bag output. It could produce around 25 ~ 35 bags per minute according to the target weight and powder features with only one labor operating. The whole machine frame and the material contacting parts are made of SS304 food-level stainless steel to meet the food production requirements. The elevator hopper is also designed with a transparent hopper cover to prevent dust and check the material level easily.

The auger dosing system adopts a side open design which could facilitate the user to maintain the machine easily. The screw is driven by the Panasonic servo motor which could better ensure the dosing accuracy. The stirring system is also equipped to protect the filling uniformity and prevent powder overheads in the filling process. The main machine is controlled by Siemens PLC with a 7″ HMI interface for operation. The operation system shall use a CH/EN double language operation interface and customized language is also available.

KEY ADVANTAGES OF POWDER VERTICAL FORM FILL SEAL MACHINE

1. Saving Labor Costs & Improve Production Efficiency: The traditional manual powder packaging methods require a lot of labor to keep working and the costs grow higher and higher with the development of the economy. Each worker’s production speed is limited and very hard to work for long hours. What’s more, mistakes occur often when the unskilled worker participates. The vertical form fill seal packaging machine could keep running at a stable high speed and only requires one worker to change the roll film when it runs out. It shall improve the production efficiency and save the labor costs greatly.

2. Improving Product Quality: When the manual participates too much in the packaging work, the food safety issue will become a problem for the factory. Thus, the VFFS packaging machine becomes very important because it shall reduce the number of workers sharply. Meanwhile, the machine could repeat the same action to seal the bag at the same size and position which could ensure better appearance bags. The high-accuracy dosing system could support the user to cut down the production waste to the minimum quantity.

FAQ ABOUT THE POWDER VERTICAL PACKING MACHINE SOLUTION

What is a powder vertical form fill seal packing machine?

The powder vertical form fill seal packing machine is a vertical packaging machine solution that packs the non-free flow powder material into a pillow-type bag or gusset-type bag with the auger dosing filling system. The machine unit runs automatically and only requires one labor to operate the machine easily.

How much does an automatic powder vertical packing machine cost?

The powder vertical packaging machine is a customized packaging system that should be manufactured according to the user’s requirements. Welcome to send your bag size and powder features to Solution-Pack, we shall provide official quotation documents for your reference.