The popularity of drip coffee bags has increased sharply in the past decades. It is portable, compact, and easy to use. We shall introduce the ground coffee packing machine for packing ground coffee into drip coffee bags today. We know that drip coffee bags have widespread appeal for special roasters who are looking to grow their customer base and offer flexibility in the way that customers drink their coffee. Here we would list out four models of drip coffee bag packing machines to help you to realize automation production and increase production capacity.

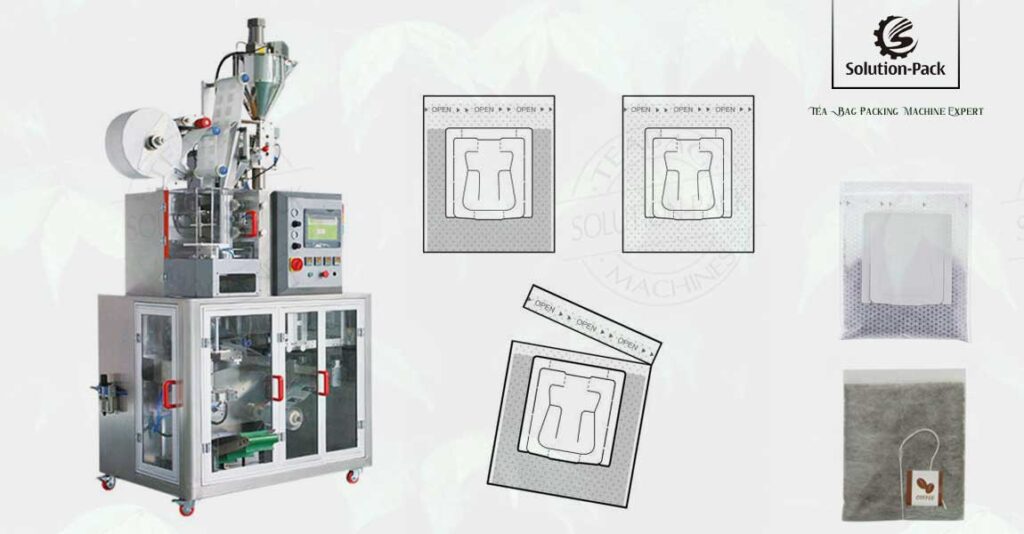

ATB-DC30 automatic drip coffee bag packing machine is a start-up machine model for the market. It could be applied to ground coffee or powdered coffee material according to the production requirements, and there are auger/cup dosing systems for option. It adopts an integrated design with stainless steel frame and contact parts. This ground coffee packing machine could form both the drip coffee bag and PLA netting rectangular bag with thread and tag. The nitrogen gas flush system could be customized and the production capacity could be stable at 1500 ~ 1800 bags per hour. This production capacity is the first choice for most start-up factories to produce neat and beautiful products for their customers.

Learn More …

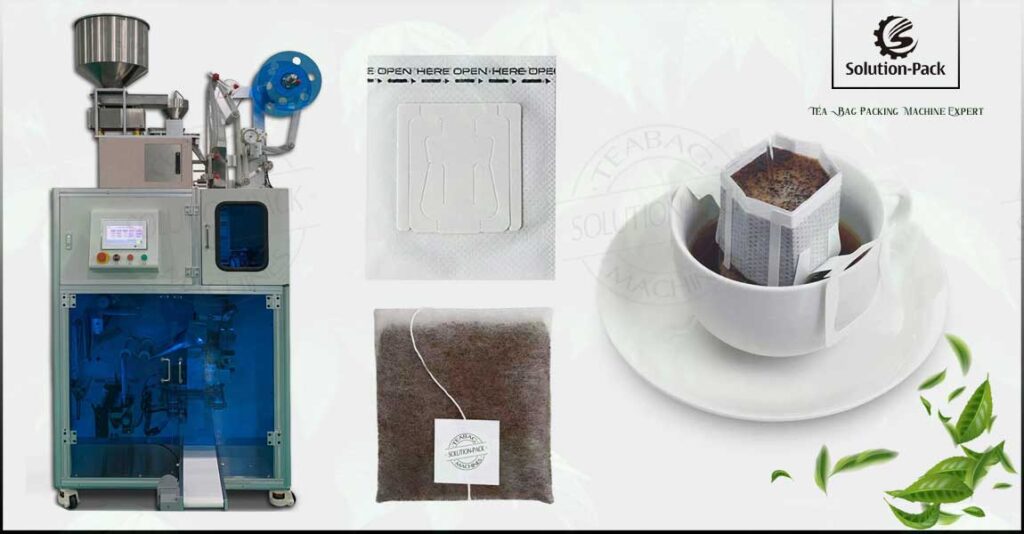

ATB-DC35 automatic drip coffee bag packing machine is the standard machine model for packing ground coffee products. This coffee packing machine is based on an integrated food safety design. The drip bag system and the outer sachet system are designed in a whole unit with a compact size. The machine frame is made of coated carbon steel and the material contact parts are made of food-level stainless steel. The automatic vacuum elevator system and nitrogen flush system could be customized according to each client’s production needs. The machine unit could perform the production capacity of 1800 ~ 2100 bags per hour. This ground coffee packing machine is suitable for small factories with limited space and a stable production schedule.

Learn More …

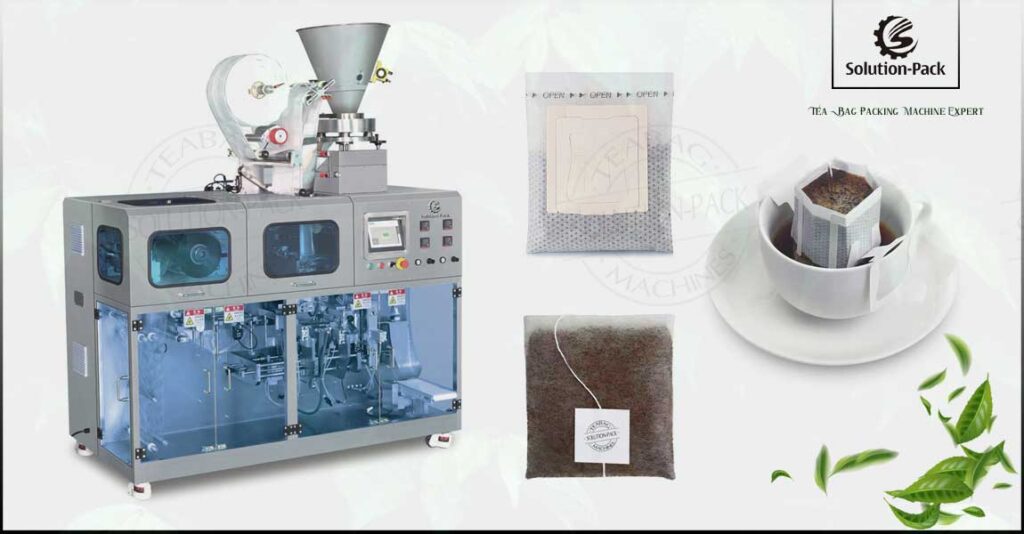

ATB-DC45 automatic drip coffee bag packing machine is a medium machine model for regular and big factories with large production capacity requirements. The machine unit also adopts an integrated design with the machine frame and material contact parts all made of food-level stainless steel. Compared with ATB-PD35 which adopts the VFFS design style, this machine unit adopts the HFFS design style which could produce a smaller and more beautiful outer sachet. Intelligent Siemens PLC, HMI, and Servo Motors are adopted to ensure better machine performance. It could also connect with the vacuum elevator and nitrogen gas flush system to realize full automation production. This machine unit could perform the production capacity of 2400 ~ 2700 bags per hour.

Learn More …

ATB-DC55 automatic drip coffee bag packing machine is a premium machine model for large factories. This machine model also adopts the HFFS design style with a coated carbon steel frame. All the electrical and pneumatic parts adopt the Fuji and SMC brands from Japan to ensure the best machine performance. Normally the machine unit shall connect with the vacuum elevator and nitrogen flush system to realize full automation production. The inner bag type could be both a drip coffee bag and a rectangular-shaped PLA netting bag with thread & tag. This machine unit could perform the production capacity of 3000 ~ 3360 bags per hour. It is the first choice of most group companies to increase their production capacity in a limited production room.

Learn More …

Market Analyze | Ground Coffee Packing Machine

The popularity of the single-serve coffee market has exploded over the past decades. And the popularity of drip coffee machines has overtaken the traditional single-cup brewing system. As a result, the drip coffee machine has become more and more popular in the present world market. And for special coffee roasters, drip coffee bags offer an effective way of marketing their brand as well as reaching new corners of the market. If you schedule to start a drip coffee packaging business or increase your present production capacity, welcome to contact us for more details regarding the machinery equipment.

To Get An Official Quotation

1. What type of coffee products do you need to pack?

2. What type of inner bag do you need to form? Any pictures?

3. How much weight do you need to pack per bag?

4. How many bags do you need to produce per hour?

5. Do you have outer sachet size requirements?

6. What’s your official company name, address, and contact number?

7. When do you schedule to install the machine unit or just want a budgetary quotation?

We would appreciate it very much if you have done market research and could provide the above details to send to our mailbox: [email protected]. And you could also submit your requirements in the right form, we shall provide the soonest feedback to get in contact with you.