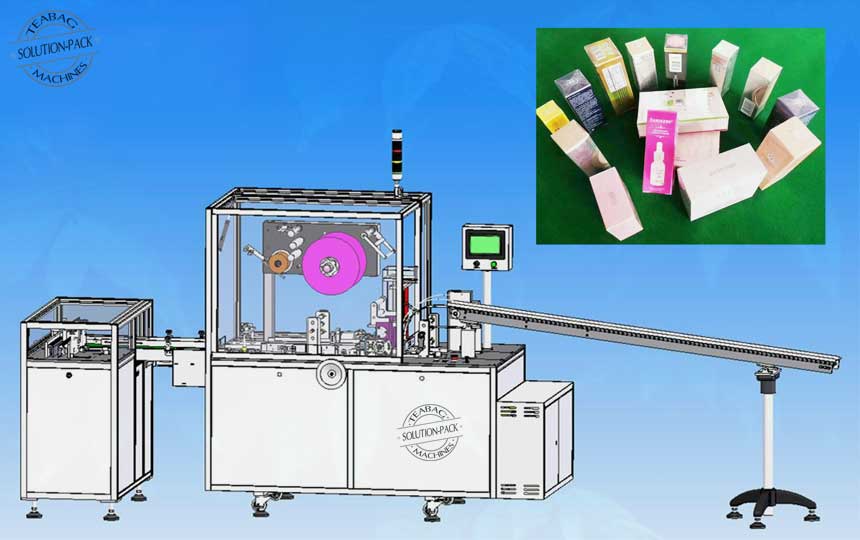

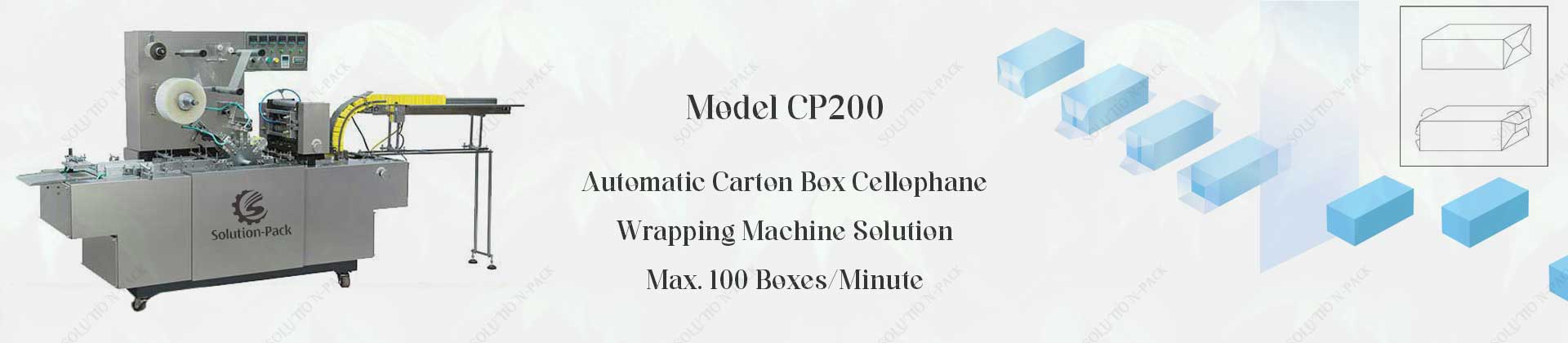

CP200 automatic box cellophane over-wrapping machine unit is the smallest machine model in the box-wrapping machine series. It is widely used in the packaging of various small-box items (with gold tear tape) in the industries of medicines, health products, food, cosmetics, stationery, audio, and video products. This machine unit adopts an automatic box stack feeding conveyor system for small boxes like lipstick boxes, perfume boxes, etc. The whole machine frame and the material contacting parts are made of stainless steel. The simple button operating system is applied for easy working performance.

Technical Data

Machine Model: CP200

Machine Type: Cellophane Wrapping Machine

Packaging Materials: BOPP Film + Gold Tear Tape (Optional)

Packing Speed: Max. 100 Boxes/Minute (As per box features.)

Box Length Range: 30 ~ 140 mm

Box Width Range: 20 ~ 80 mm

Box Height Range: 6 ~ 30 mm

Voltage Supply: AC220V Single Phase 50Hz

Powder Supply: Around 5Kw

Air Supply: 0.6 ~ 0.8Mpa | Around 0.3 Cubic Meters/Minute

Machine Weight: N.W. 700kg | G.W. 800kg

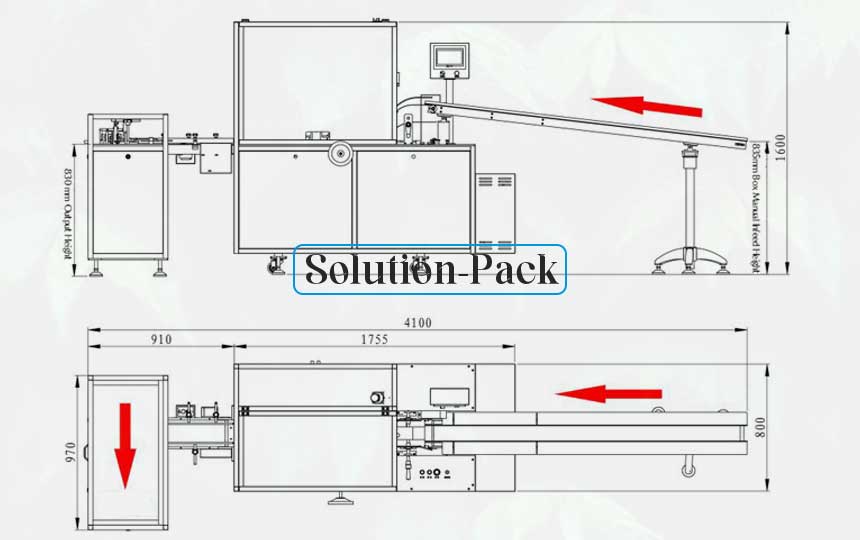

Machine Size: (L) 4100 mm × (W) 800 mm × (H) 1600 mm

Typical Features of Cellophane Over-Wrapping Machine Solution

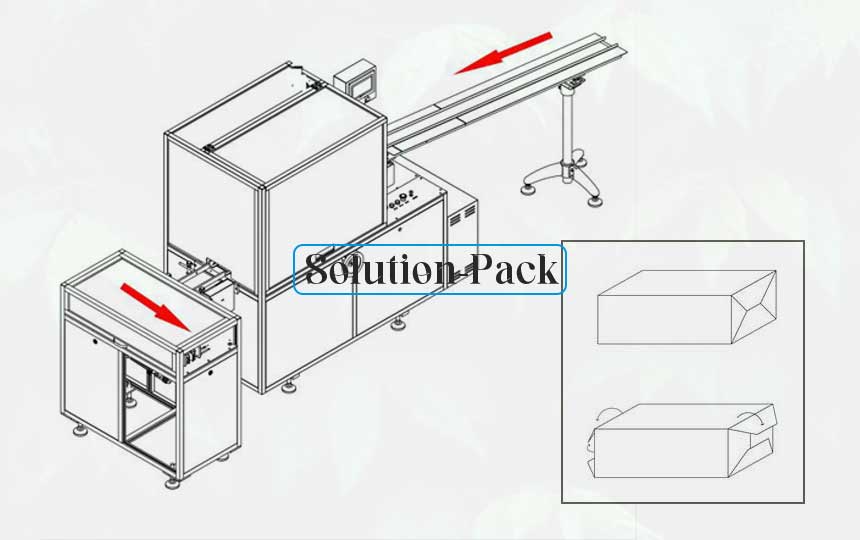

This cellophane wrapping machine unit could realize the function of box conveyor feeding, horizontal pushing of the box, film cutting & wrapping, down film folding, long-side folding sealing, corner folding, up & down film wrapping, right & left side heat sealing, up & down heat sealing, and final box output. The new updated wrapping machine model shall adopt 7 inches Mitsubishi touch screen with PLC control to operate the machine which is much easier and simple to use. The fast mold change design only requires 20 minutes to change full sets of molds. Meanwhile, the width and the length data could operate on the HMI directly.

Once the box is stuck or the machine has a problem, the machine shall stop and alarm. All the mechanical moving parts are fully covered. The machine shall stop and alarm if the safety door opened during production. The HMI operating interface shall be English / Chinese double language, and the user could choose the language directly as they need; All the alarm marks on the machine shall be English warning type. Meanwhile, The film-cutting blade could use more than 2 years before sharpening. This economical cellophane wrapping machine is widely adopted by cosmetic factories that produce with large production capacities.

Choose Solution-Pack, Get The Smart & Intelligent Cellophane Over-Wrapping Machine Solution

Solution-Pack is one of the leading teabag packing machine manufacturers from China. We also supply our clients with box-wrapping machines to meet the tea factory production needs. As a box wrapping machine supplier, we aim at providing mature and stable performance packing machine solutions for users. The molds on the machine are seriously customized to each user’s exact boxes to ensure accuracy. Solution-Pack also supplies official CE certification for European friends to import the machine easily.

Solution-Pack provides a sample box testing service for start-up companies who are new to this type of machine. The client could deliver around 200 pcs of pre-fold boxes to our factory, then we shall customize the mold device for the box. After the molds were manufactured, we shall equip them on the cellophane wrapping machine to test with the delivered boxes directly and then take the machine running videos for the clients to check the exact machine running performance directly. Each box size means one set of mold, and we shall charge the customized mold cost for the machine testing service.

To Get The Official Quotation

1. Do you have only one box size or different box sizes?

2. What are the exact box sizes? If you have the box design documents?

3. How many boxes do you need to pack per minute?

4. Do you need to connect with the front production line?

5. If you need other functions after the box output?

6. What’s your official company name, address, and contact number?

7. When do you need to install the machine unit or if you just need a budget?

We shall work our best to support your project after you prepare the above details and send them to our official mailbox: simon@solution-pack.com. We shall reply within 12 hours.

Solution-Pack also provides packaging material service for clients who are interested in the box wrapping machine solution. We shall propose the most suitable packaging film width for the clients after they offer the exact box sizes. According to the production capacities and box sizes, we could also count out the estimated quantities of the Bopp film that the clients need per year or how much could load in the rest of the container. In this way, it could save a lot of time for the clients to source the correct packaging materials.