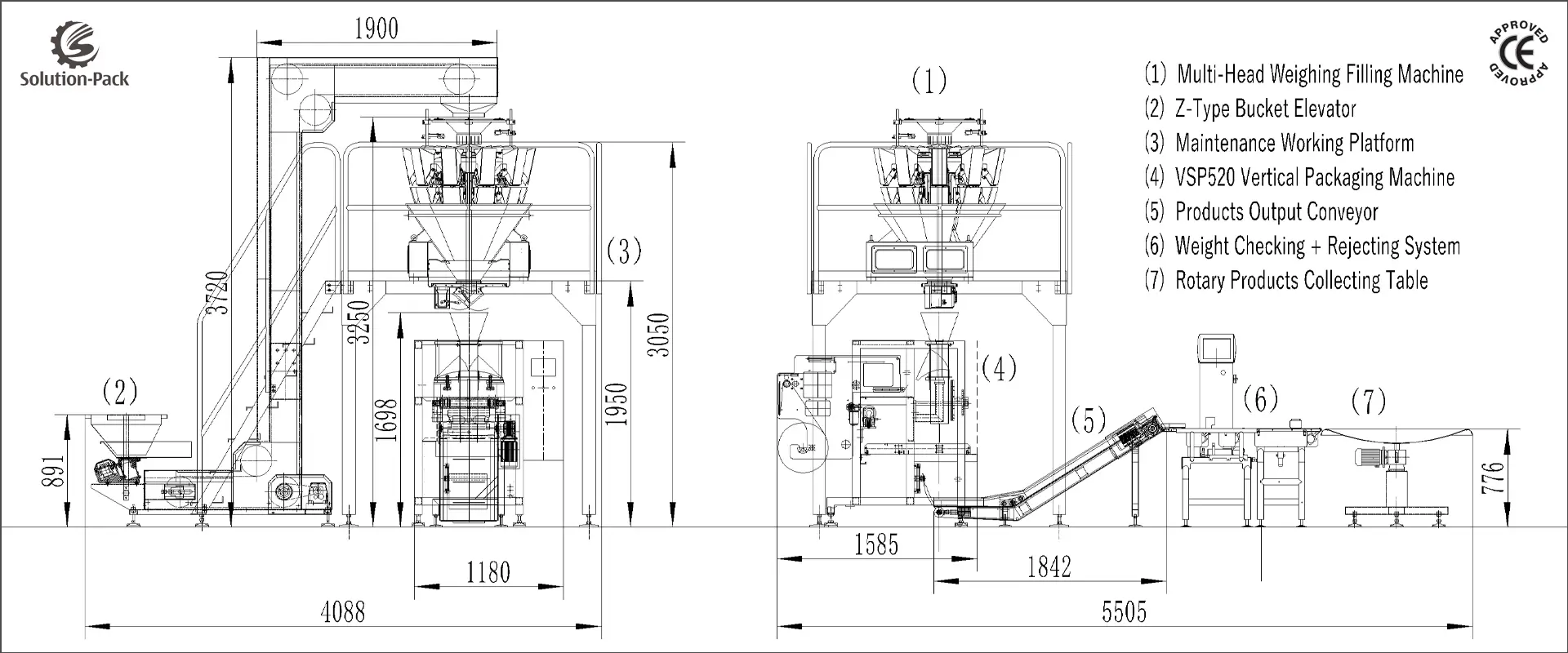

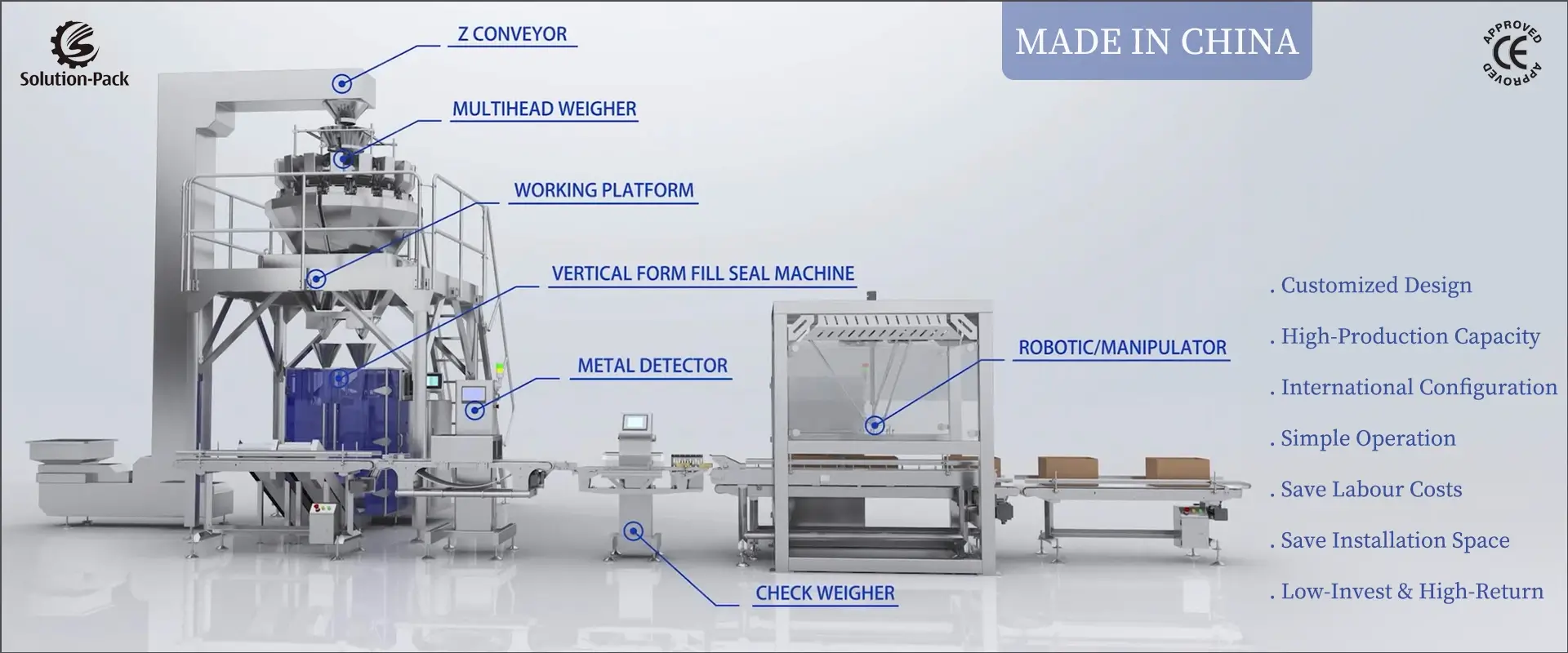

Cashew nuts packaging machine solutions are now widely applied in cashew nuts manufacturing factories to package the products into bags, pouches, or jars. The basic and economical packaging pattern is Pillow-Type Bags which is produced by the vertical form fill seal packaging machine equipment. This solution generally consists of the Z-Type Elevator, Multi-Head Weighing Filling Machine, Maintenance Working Platform, Vertical Packaging Machine, and Products Take-Off Conveyor. Other devices like the Metal Detector, Weight Checker, Nitrogen Filling Machine, and Rotary Collecting Table are optional for choosing depending on the exact production needs. The most adopted vertical packing machine model is VSP520M.

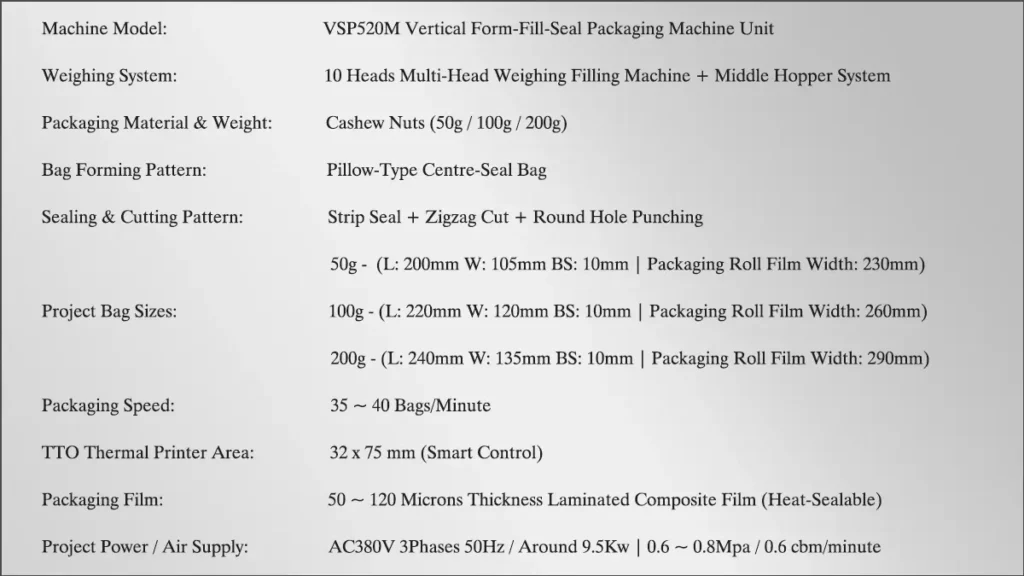

VSP520M CASHEW NUTS PACKAGING MACHINE TECHNICAL SPECIFICATIONS

This VSP520M vertical packaging machine unit connects the 10-head weighing filling machine to package 50 ~ 200 grams of cashew nut products into the centre-seal pillow bags. It could produce around 35 ~ 40 bags per minute with the middle hopper system. This is the most appropriate production speed to protect the cashew nuts during the filling process. It could connect the nitrogen filling system to insert the N2 gas into the bags to extend the shelf time of the products. The automatic weight-checking machine will be equipped to reject unqualified products. All the machine frame and material contacting parts are made of food-level stainless steel to meet GMP production requirements.

SUBMIT HERE TO CONTACT US

TYPICAL FEATURES OF THE CASHEW NUTS PACKING MACHINE SOLUTION

Model VSP520M automatic granule vertical form fill seal packaging machine unit is designed for packaging regular or irregular granule products like rice, beans, chips, nuts, grains, seeds, snack food, dried fruits, candies, etc. The entire machine frame and the material contacting parts shall all be made of food-level stainless steel to meet the food production requirements. The weighing system shall adopt a mirror face board for easy daily cleaning. The middle hopper system could support reducing the falling distance to avoid material breaking in the filling process.

This machine unit is composed of the Z-Type Bucket Elevator, 10 Heads Multi-Head Weighing Filling Machine, VSP520 automatic vertical packing machine, TTO Thermal Printer, Working Platform, Products Take-off Conveyor, Weight Checking and Rejecting System, and the Rotary Products Collecting Table. It shall realize the function of automatic material elevating, weighing, film pulling, date printing, bag forming, material filling, heat-sealing, hole punching, final products taking off, weight checking and unqualified products rejecting. The main machine shall adopt a 10.4” HMI interface with customized button operation. Both HMI and PLC control shall use Germany Siemens or an equal brand. Other electrical parts also adopt the internationally famous brand which could be checked at the configuration parts directly.

Choose Solution-Pack | The Best Cashew Nuts Vertical Packaging Machine Solution

Solution-Pack provides customized vertical form-fill-seal cashew nuts packaging machine solutions for worldwide users to realize automatic production. These solutions could automatically support users in packaging 50 ~ 200 grams of cashew or similar dried nuts into center-seal bags with high production capacity. Besides realizing the basic function of packaging, we also provide optional functions like nitrogen gas filling, hole punching, weight checking, unqualified bag rejecting, and qualified bag collecting. The machine’s bag-forming collar device which adopts an integrated design pattern is fully customized to the user’s roll film widths. Solution-Pack provides official CE certification for all equipment.

Most users are concerned about the machine’s installation and after-service. We offer two types of options according to the user’s needs. The first option is on-site installation and training service. It is suitable for users who are the first time to use automatic packaging machine solutions and require detailed instructions to support the operators. We shall send engineers to the site to support the installation and training work. The second option is remote online installation and training service. It is suitable for users familiar with the packaging machine equipment and has professional technicians. We will do this work via WhatsApp or WeChat. No matter which option users choose, we shall create an after-service group for users to communicate instantly.