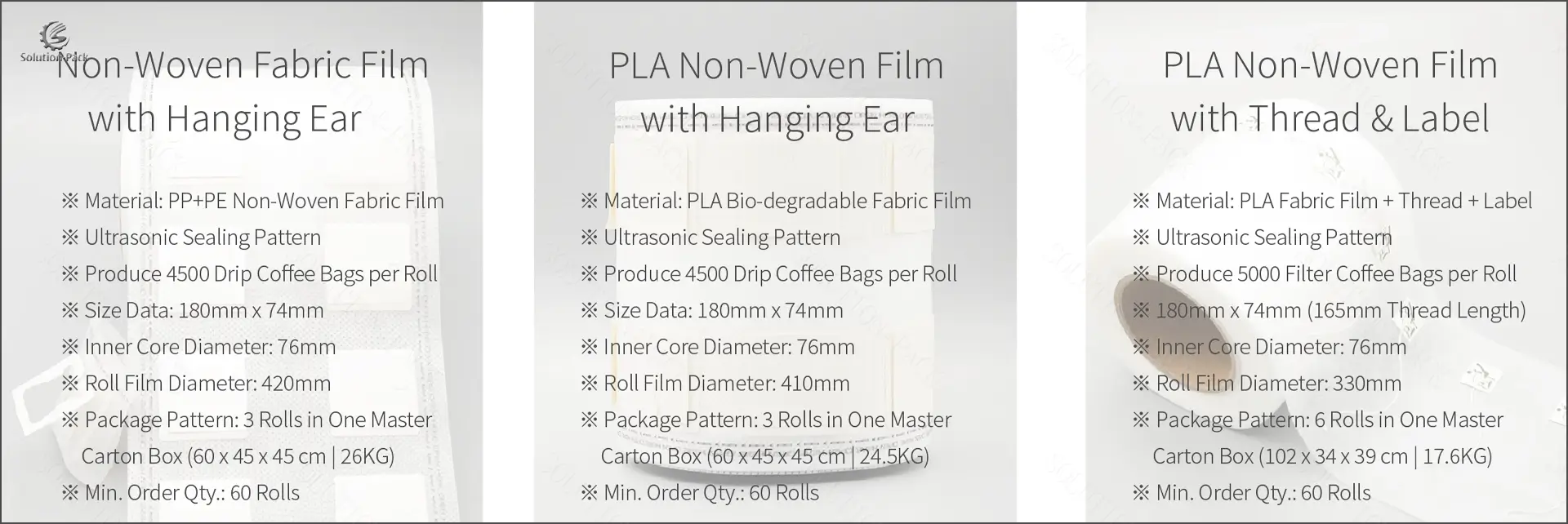

The drip coffee bags become increasingly popular in the present coffee drink market with the life pace moving faster and faster. This kind of ground coffee packaging pattern could better facilitate the drinkers to save time getting a hot cup of coffee and keeping the original taste. Normally the drip coffee bags are packed by the non-woven fabric film with hanging ear or the PLA non-woven fabric film with thread and tag. How are the drip coffee bags produced? We shall introduce 3 kinds of typical drip coffee packing machine solutions here for the factories to start the coffee bag packaging business or improve their production efficiency. These solutions shall offer you a clear idea of how the whole process works.

DRIP COFFEE BAG PACKAGING MACHINE SOLUTIONS

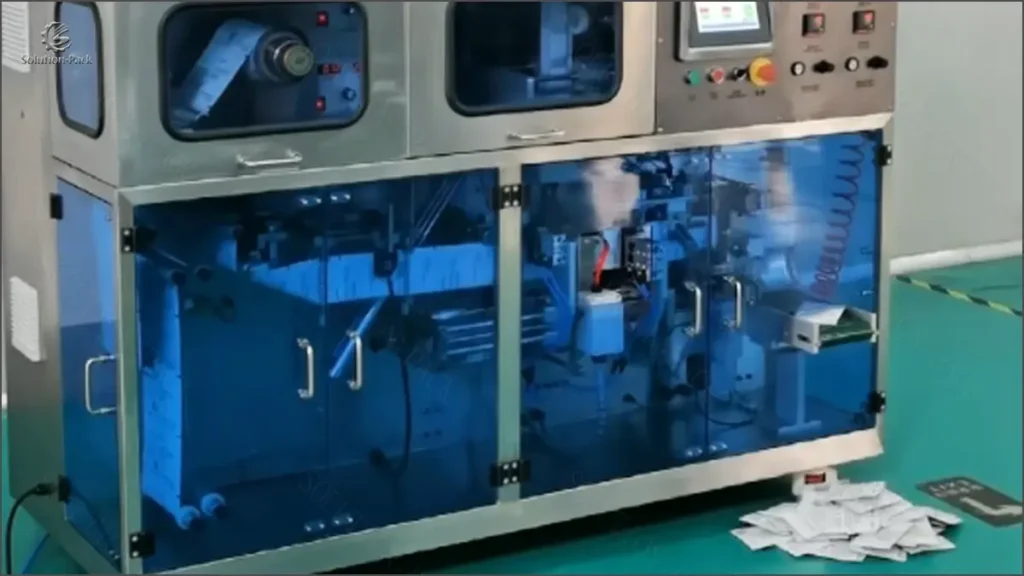

The drip coffee bag packing machine is a type of packaging equipment that makes drip coffee bags and then wraps them into outer foil sachets automatically. It could package 10 ~ 16 grams of ground coffee or coffee powder into the bag. Different machine models adopt unique mechanical design methods to insert the inner coffee bag into the outer foil sachet. The sealing and tear notch patterns could be customized per production needs. The standard machine unit could produce 30 ~ 35 sachets per minute and the premium machine model could produce 50 ~ 55 sachets per minute. We also provide the automatic vacuum elevator system and nitrogen gas filling system for the chosen.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE DRIP COFFEE BAG PACKING MACHINE SOLUTIONS

1.) Compact Design: These coffee bag packing machines adopt an integrated design style. The automatic volumetric cup dosing system, the inner drip coffee bag forming system, and the outer sachet wrapping system are designed on a whole machine unit. When the vacuum elevator system is equipped, it shall be combined with the hopper of the dosing machine directly. This design method could ensure the whole machine unit is compact for installation and save space for the users. With the universal wheels equipped at the foot of the machine, the users could move the machine easily at the warehouse for convenient production;

2.) Efficient Production Capacity: These drip coffee packaging machines are excellent for users to start their coffee bag packaging business or improve their production efficiency. The economic machine model could produce around 30 ~ 35 sachets per minute for the start-up users. The standard machine model could produce 40 ~ 45 sachets per minute for most coffee factories. The premium machine model could produce 50 ~ 55 sachets per minute for the big production line. All the machine units adopt the ultrasonic sealing technology which could work perfectly for non-woven fabric film and PLA non-woven fabric film.

3.) High Standard Configuration: Most electrical and pneumatic parts adopt internationally famous brands to ensure the best machine-using experience for the clients. The PLC Control and the HMI display shall use Japan Fuji or German Siemens brand, the pneumatic parts shall use the Japan SMC, China AirTac brand, and the electrical parts shall use the France Schneider, Japan Omron, or equal brands. It could facilitate the users to source them easily at the local market. All the machine frames shall be made of coated carbon steel with great strength, and the material contacting parts shall be made of food-level stainless steel to meet the production requirements.

CHOOSE SOLUTION-PACK | FIND THE BEST DRIP COFFEE BAG PACKAGING EQUIPMENT

Solution-Pack is a leading packing machine manufacturer and trader in China with over 12 years of experience. We have professional assembling workers, technical teams, and marketing departments. Our major markets include snack foods, daily care products, cosmetics, tea, coffee, grains, seeds, animal feeds, pet foods, and chemical fertilizers. We treat each project seriously and comprehensively study users’ detailed requirements before proposing suitable and applicable packaging solutions. We offer high-standard machine equipment with official CE certification from ECM and all the goods will be packed in non-fumigation export wooden cases. Welcome friends worldwide to contact and work together with us to build up their projects!

After-sale service is the priority in our work and users’ experience is the top mission of our enterprise. When the equipment arrives at the user’s warehouse, we will send a professional engineer to the site for installation and training. Some users could use WeChat or WhatsApp to contact us for remote installation guidance for some simple machine models. The English version diagram and manual operation book will be delivered with the machine to support users in learning the machine before installation. What’s more, we could also help users in packaging film design works and choosing suitable packaging films to save costs for them.

FAQ ABOUT DRIP COFFEE PACKING MACHINE

What is the drip coffee bag?

The drip coffee filter bag is filled with ground coffee. It is portable and compact. Normally, the N2 gas is filled in every sachet to keep the taste and aroma fresh until just before serving. It offers coffee lovers the freshest and simplest way to enjoy coffee anytime and anywhere. All you need to do is tear it open, hook it over a cup, pour in hot water, and enjoy!

How to choose the coffee bag packing machine?

The drip coffee bags are of standard sizes all over the world. Thus, the users only need to consider the target production capacity and choose the suitable machine model for production. As for the other optional functions, the users could contact Solution-Pack to get a professional proposal for the project.

How to install the drip coffee packing machine?

The drip coffee bag packing machines adopt the integrated design style and most machine parts shall not be torn before delivery. The users only need to assemble it easily when the wooden case arrives at their factory. Meanwhile, professional technical installation service shall also be provided when the users prepare to start the machine for production.