The filter teabag is a popular type of instant drinking method in modern society. Compared with the traditional way of brewing tea leaves, the filter paper teabag could save a lot of time for the drinkers to get a hot cup of tea directly. Different types of teabags shall adopt various teabag packaging machines to realize the automatic packaging process. The most commonly used filter teabags in the market now are the naked filter paper tea bag, filter paper tea bag with thread and tag, foil-wrapped filter paper tea bag, paper-wrapped filter paper tea bag, and the double chamber filter paper tea bag. These tea bags are applicable for holding broken tea leaves, CTC black tea, broken herbal tea, medicine tea, etc. with mesh sizes around 20 ~ 60 meshes.

Filter Teabag Packaging Machine Solutions

There are different kinds of filter paper teabag packaging machine solutions for options. Each machine unit could produce specific teabags with a fixed stable production capacity. Users only need to check what type of teabag they need to make and how many teabags they need to produce per minute to select the correct machine model for production. All the teabag packaging machine solutions adopt advanced mechanical design patterns which ensures stable production performance. No matter if you are looking for a start-up machine unit, or if you are aiming to improve production efficiency, there will be one machine unit below to fit your needs well.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE FILTER PAPER TEABAG PACKAGING MACHINE SOLUTIONS

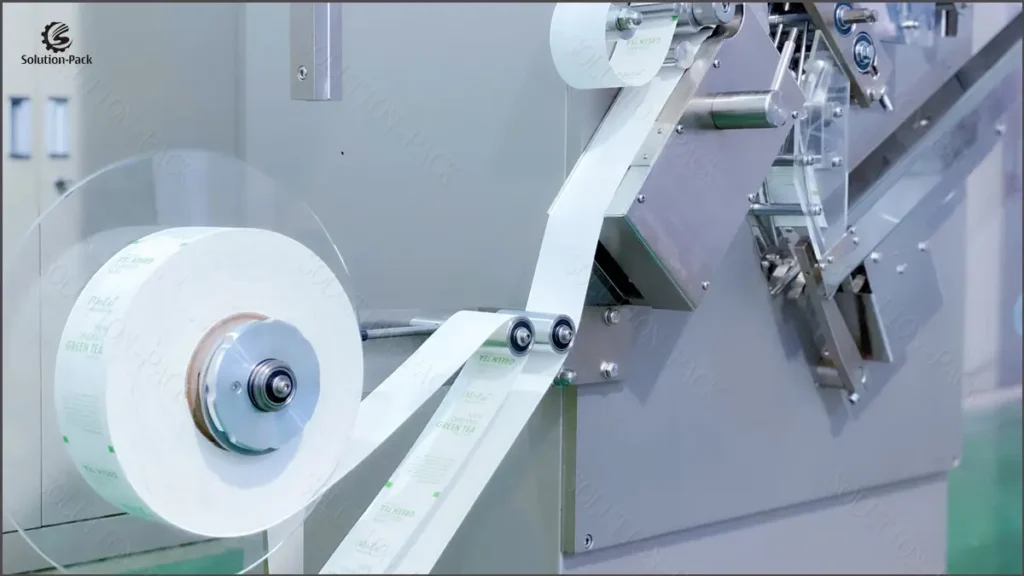

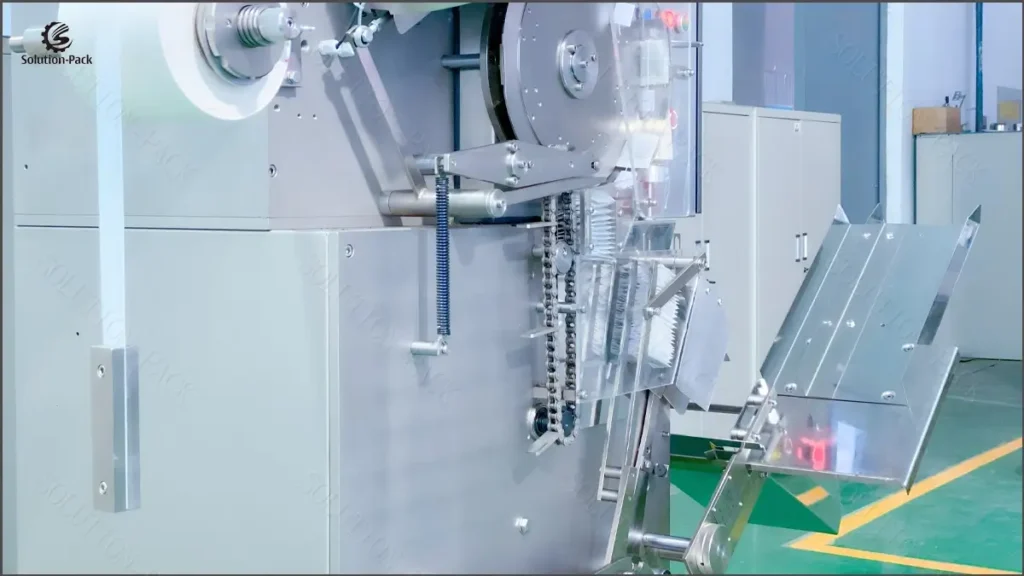

1.) Unique Design Style: all the tea bag packaging equipment adopts the integrated design style with all the functions on a whole machine unit. The users could connect the machine to the vacuum elevator system to realize continuous production without stopping the machine and then feed material manually. The ATB-S1 machine model is an economic multi-functional model that could produce different types of teabags for most of the start-up factories. The other machine models are designed to produce unique standard filter tea bags with high production efficiency.

2.) High Production Efficiency: except for the model ATB-S1 which is designed for start-up factories that could perform a stable production speed of 35 ~ 45 bags per minute, the other machine models are all designed for high packaging speed. The ATB-S150 machine model could produce 140 teabags per minute, the STB-S130N machine model could produce 120 teabags per minute, the ATB-C6/10 machine model could produce 105 sachets per minute, and the DC120 machine model could perform the speed of 120 double chamber teabags per minute. These machine models could support the users to improve production efficiency effectively.

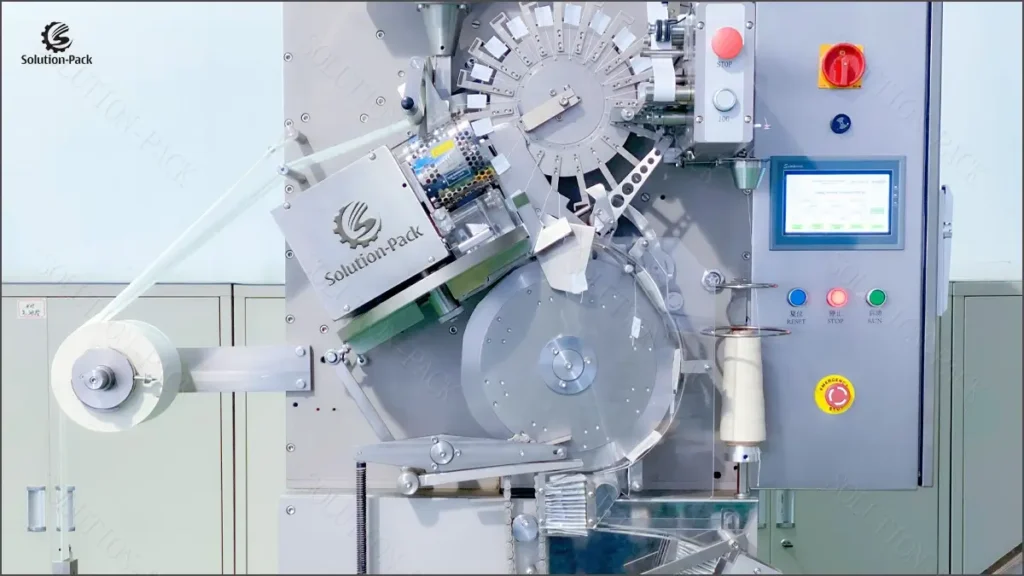

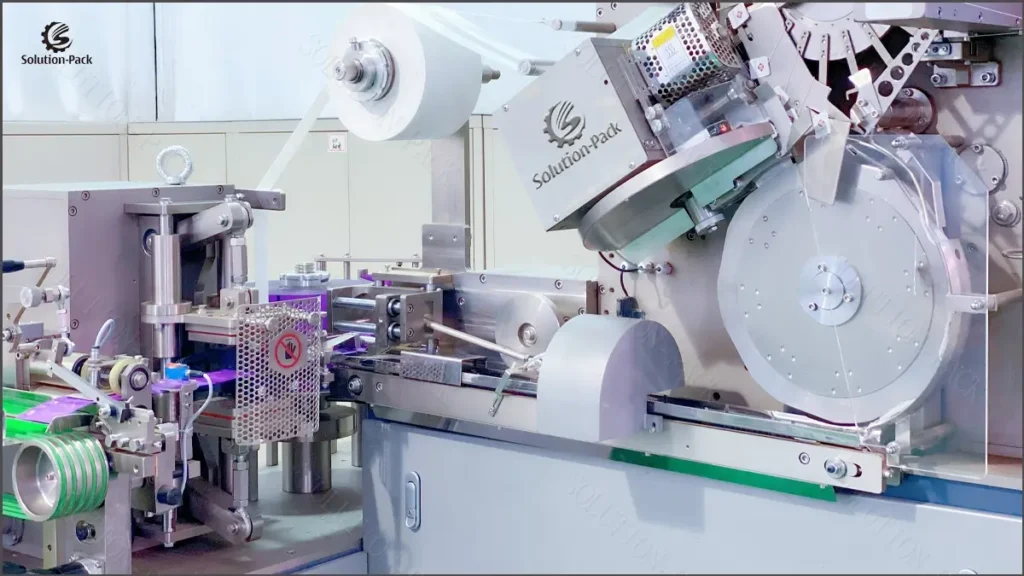

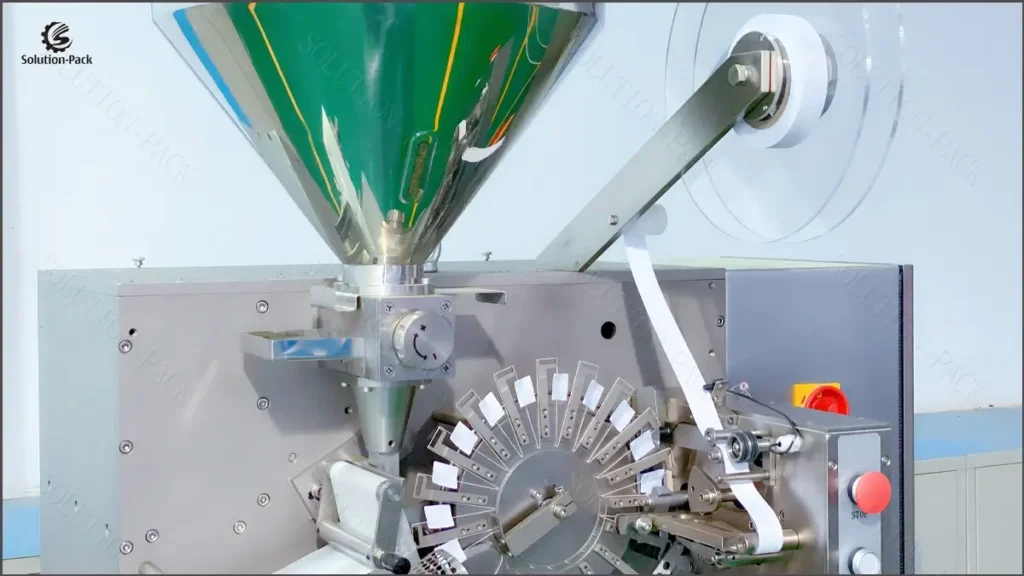

3.) High-Standard Configuration: to better ensure the machine running stable in the overseas market, we adopt the internationally famous brand electrical and pneumatic components on the machine unit to facilitate the users sourcing spare parts easily at the local market. All the machine frames shall use coated carbon steel with great strength, and all the material contacting parts shall use food-level stainless steel to meet the food production requirements. The transparent safety door system could be customized according to each customer’s production needs. The users could visit our YouTube Channel to see how the machine works.

FEATURED TEABAG PACKAGING MACHINE DETAILS VIEW

FAQ About The Filter Tea Bag Packing Machine Solution

How to choose the filter tea bag packaging machine equipment?

There are different types of filter tea bag packaging methods in the market. The user must do market research and confirm clearly what kind of bag type they want to produce and what’s their target bag sizes. Then Solution-Pack shall propose the most suitable machine models for their reference based on their exact requirements. The start-up users could also read our introduction on different types of filter tea bag packing machines to get a brief idea about the equipment before moving forward.

How to install the filter paper teabag packing machine?

The filter paper teabag packing machines are of standard design style. The users could charge the electricity to use directly when the machine arrives at the site. We could also arrange for the engineers to go to the site to do the training and maintenance work if the users do not have an engineering team. Remote video instruction is also available to support the users to save installation and training costs.