The gusset bag is also one of the most popular packaging patterns in the international market. It is also called the “Side-Gusset Bag” in some areas of the world and it is a simple packaging pattern in the packing machine market. Generally, it could be produced by the vertical packaging machine with customized bag collars. This packaging pattern is widely used in food, chemical, seeds, grains, and feed mill markets. Solution-Pack shall introduce different models of VFFS machines that could produce gusset bags of various sizes. Users could choose suitable machine models according to their target packaging weight and bag sizes.

GUSSET BAG VERTICAL PACKAGING MACHINE SOLUTIONS

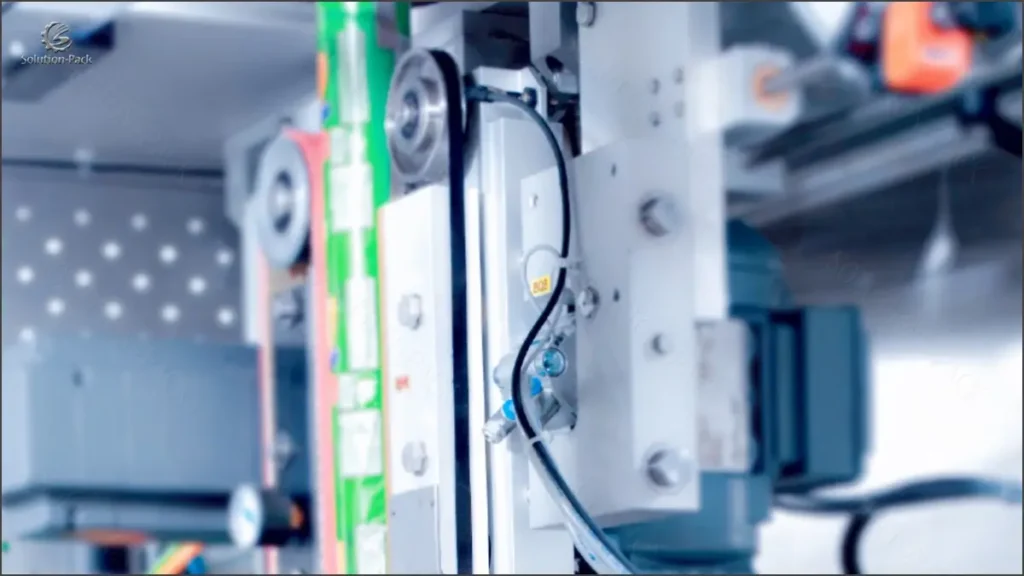

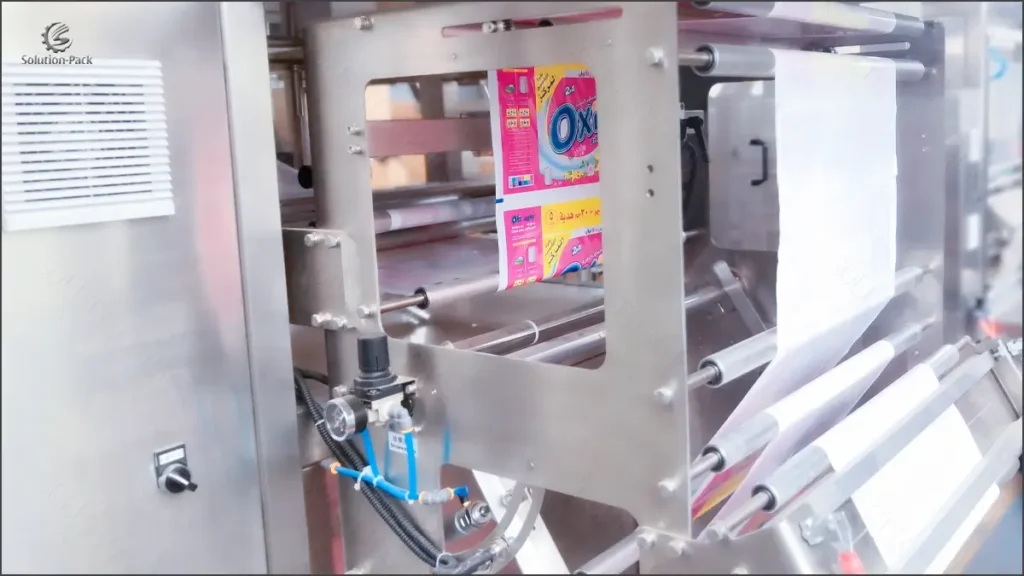

The vertical form-fill-seal packaging machine equipment adopts unique customized forming collar devices to shape the roll film into a bag. It could connect different weighing filling and elevating systems to package powder, granule, or liquid products. Each machine unit has a certain fixed bag packaging width and weight range. Users could produce different bag sizes by changing the forming collar devices within this range. The side gusset device works after the material filling and before the heat-sealing process. The basic machine model could produce 30 ~ 50 bags per minute and the production capacity shall decrease when the model number becomes bigger. Welcome to check the typical machine models below:

ADVANCED FEATURES OF THE VERTICAL FORM FILL SEAL MACHINE SOLUTION

1.) Customized Solution Design: The gusset bag packaging machine is the most commonly adopted packing machine solution in the world market to produce different materials into bags. Solution-Pack shall confirm and collect the detailed packaging requirements with the users and propose the most suitable packaging machine unit. Different dosing filling systems shall be adopted according to packaging materials. And the models of the weighing machine shall also differ according to the users’ packaging weight. Users could also request the metal detector system, check weigher system, baling system, or carton boxing system to form a complete packaging production line.

2.) Easy Operation & Maintenance: All the vertical packaging machine models adopt intelligent Siemens PLC control and HMI display to facilitate users’ operation. Meanwhile, other related electrical and pneumatic parts also use internationally famous brands that ensure users source spare parts easily at the local market. They could also get from us directly. All the machine frame and the material contacting parts are made of food-level stainless steel and only some non-important parts are made of coated carbon steel with better strength. It could allow the users to do the daily maintenance and cleaning work easily.

3.) High Production Efficiency & Save Labor Cost: Compared with the traditional manual packaging method, the gusset bag packing machines could produce gusset-type bags at high production capacity with stable performance. It allows fewer labourers to participate in the production process which could better ensure food production safety. Meanwhile, it could save labour costs and solve the instability issue of workers in continuous production.

SUBMIT HERE TO CONTACT US

CHOOSE SOLUTION-PACK | FIND THE BEST GUSSET BAG PACKAGING MACHINE EQUIPMENT

Solution-Pack is a leading packing machine manufacturer and trader in China with over 12 years of experience. We have professional assembling workers, technical teams, and marketing departments. Our major markets include snack foods, daily care products, cosmetics, tea, coffee, grains, seeds, animal feeds, pet foods, and chemical fertilizers. We treat each project seriously and comprehensively study users’ detailed requirements before proposing suitable and applicable packaging solutions. We offer high-standard machine equipment with official CE certification from ECM and all the goods will be packed in non-fumigation export wooden cases. Welcome friends worldwide to contact and work together with us to build up their projects!

After-sale service is the priority in our work and users’ experience is the top mission of our enterprise. When the equipment arrives at the user’s warehouse, we will send a professional engineer to the site for installation and training. Some users could use WeChat or WhatsApp to contact us for remote installation guidance for some simple machine models. The English version diagram and manual operation book will be delivered with the machine to support users in learning the machine before installation. What’s more, we could also help users in packaging film design works and choosing suitable packaging films to save costs for them.