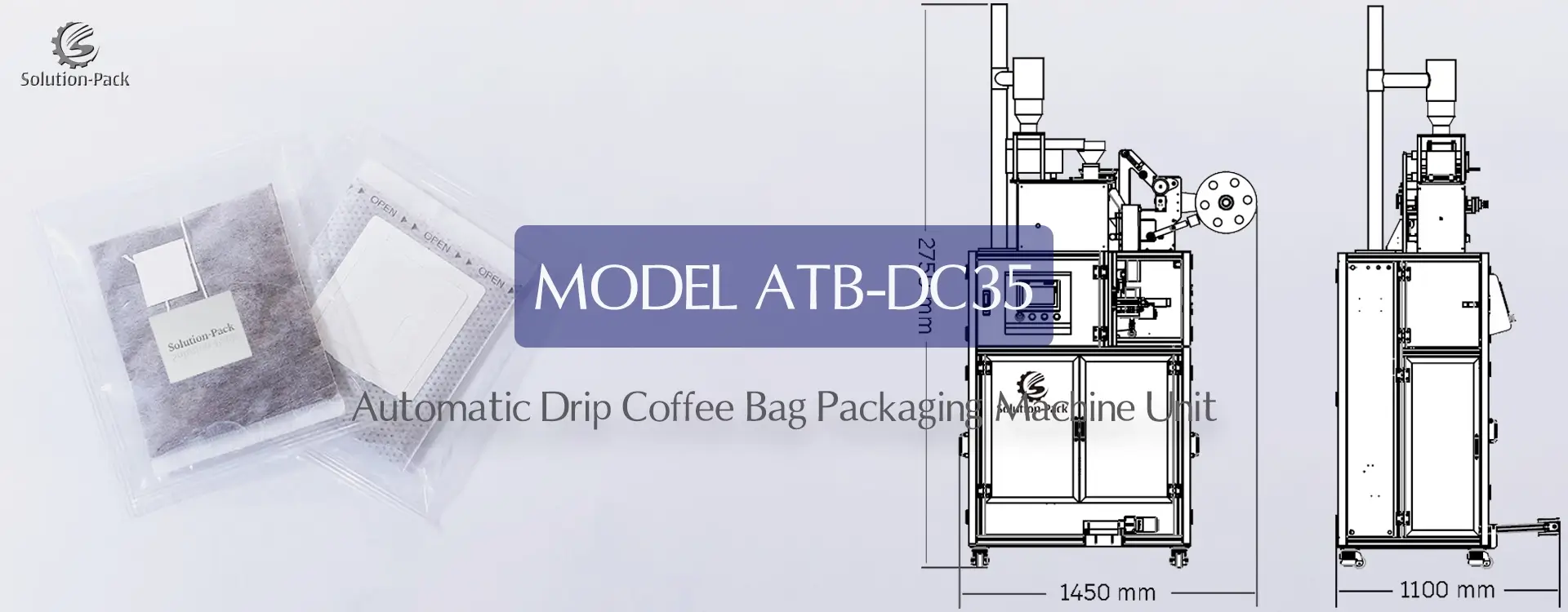

The ATB-DC35 model automatic drip coffee bag packing machine unit is based on an integrated and food safety design style. The inner drip coffee bag packing system and the outer envelope sachet bagging system are designed in a whole machine unit. All the material contacting parts are made of SUS304 food-level stainless steel which complies with the food sanitary standards. The core components of the equipment are internationally famous brands that have strong substitutability and are easy to source at the local market. This standard machine unit could produce around 30 ~ 35 sachets per minute to support the users improving the production capacity and saving labor costs effectively.

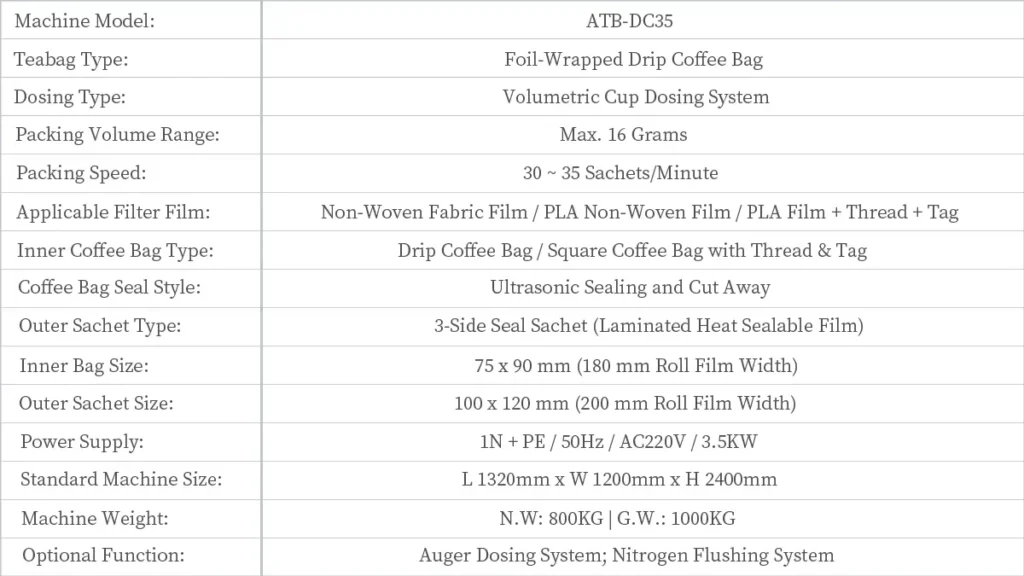

MODEL ATB-DC35 | TECHNICAL DATA

This packaging machine unit adopts the volumetric cup dosing system and is mostly used for packing ground coffee products into the drip coffee bag or rectangular bag with thread and tag. It could dose max. 16 grams of ground coffee products and the market packs 10 ~ 15 grams generally. The advanced ultrasonic sealing system from Solution-Pack allows stable performance for this machine. The vertical compact and integrated design requires less installation space and produces standard inner/outer bags. It is a basic model coffee powder packaging machine that requires less budget and is suitable for most start-up coffee factories or coffee workshops.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE DRIP COFFEE BAG PACKING MACHINE

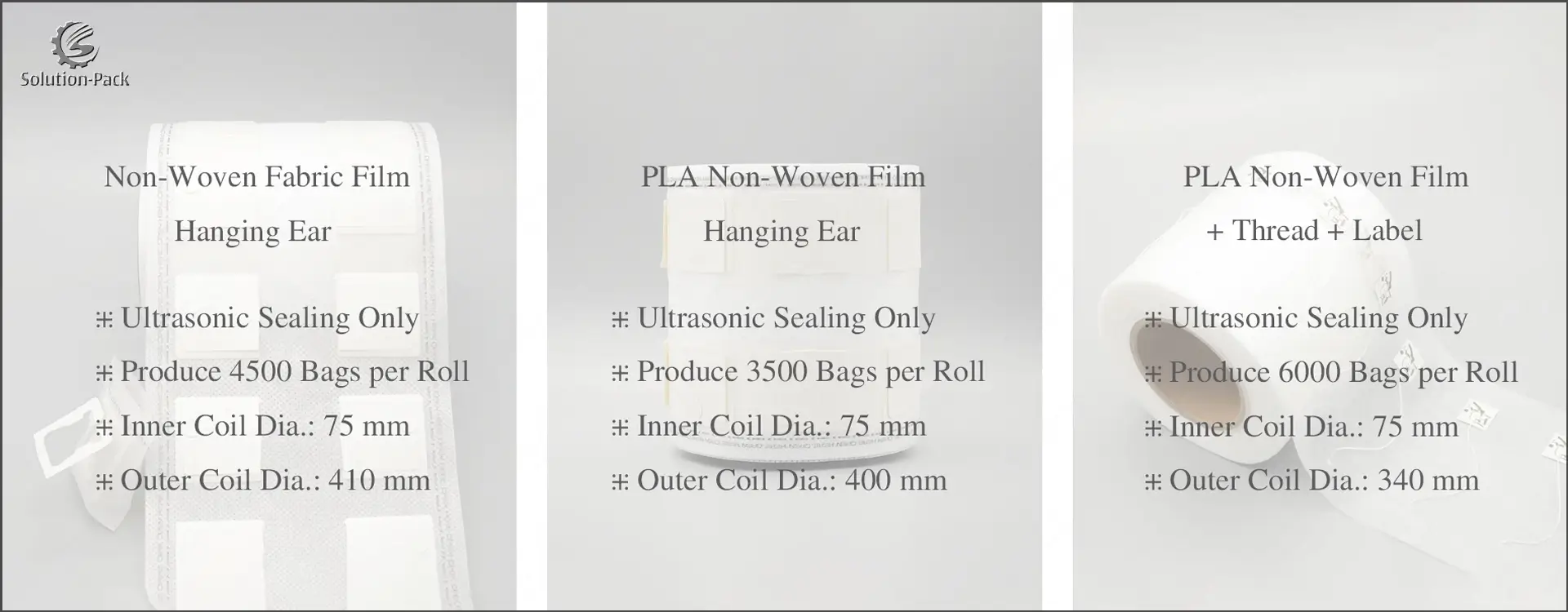

- Compared with most drip coffee bag packing machines on the market, the main characteristic of Solution-Pack is flexibility and versatility, except for the most common example of drip coffee bags. The ATB-DC35 machine model could also produce flat coffee bags with thread and labels. This coffee bag packaging machine adopts 3-side ultrasonic cutting and sealing technology which could produce neat and beautiful drip coffee bags. The whole machine unit adopts an integrated design style which is compact in size and easy to install;

- This drip coffee bag packing machine adopts an intelligent Siemens HMI Touch Screen and PLC control system to ensure easy operation. The whole operating system meets the thinking way and the use customs of the user. The other electrical and pneumatic parts mostly adopt internationally famous brands to ensure that the user can source them easily at the local market. This drip coffee packaging machine unit has high production efficiency with a speed of up to 1920 bags per hour (1800 bags per hour when inputting Nitrogen Gas). The automatic vacuum elevator system shall be provided as optional, we would design the connection with a material-level sensor system to ensure continuous production for the client;

- Nitrogen Gas input device is reserved on the machine unit, and the client could choose to input Nitrogen or not freely according to the production requirements. All the material contacting parts are made of SUS304 stainless steel. The machine frame parts are made of coated carbon steel. The safety door is made of Lexan Transparent board to ensure the client checks the machine’s running state. We could customize several machine units together to connect with the automatic boxing machine for the users that require huge production capacity.

- Compared with the traditional method of brewing coffee, the drip coffee bag is more convenient and time-savable. It is widely applied at home, office, and business occasions. Solution-Pack has focused on coffee bag packaging machines for over 12 years with rich experience. We offer different kinds of machine models to meet the client’s production requirements. All the machine models adopt an integrated design style which could save installation space and easy to operate. Each machine model has been running at the users’ present with stable performance;

- Solution-Pack also supplies sample material testing services for the new factories. The client could deliver around 2 kg of vacuumed packed coffee material to us and we shall arrange the machine testing and take a video for the client to check the machine running performance for their products. We could also supply the client with customized packaging materials: Non-woven Fabric Drip Coffee Bag Film/PET Netting Film Roll with Label and Tag/PLA Netting Film Roll with Label and Tag/Nylon Netting Film Roll with Label and Tag.