The ATB-10R automatic round teabag packing machine unit could stably complete the production of round filter paper teabags. It uses good permeability heat-seal type filter paper as packing material for the round teabags and guarantees well-infused flavorful tea. This teabag packaging machine could perform a stable running speed of 15 ~ 30 round teabags per minute according to the tea product features. It is suitable for packing tea or coffee products with smaller particles, such as ground coffee, broken tea, tea dust, and even desiccant, etc. It is suitable for most start-up factories or workshops with a limited budget.

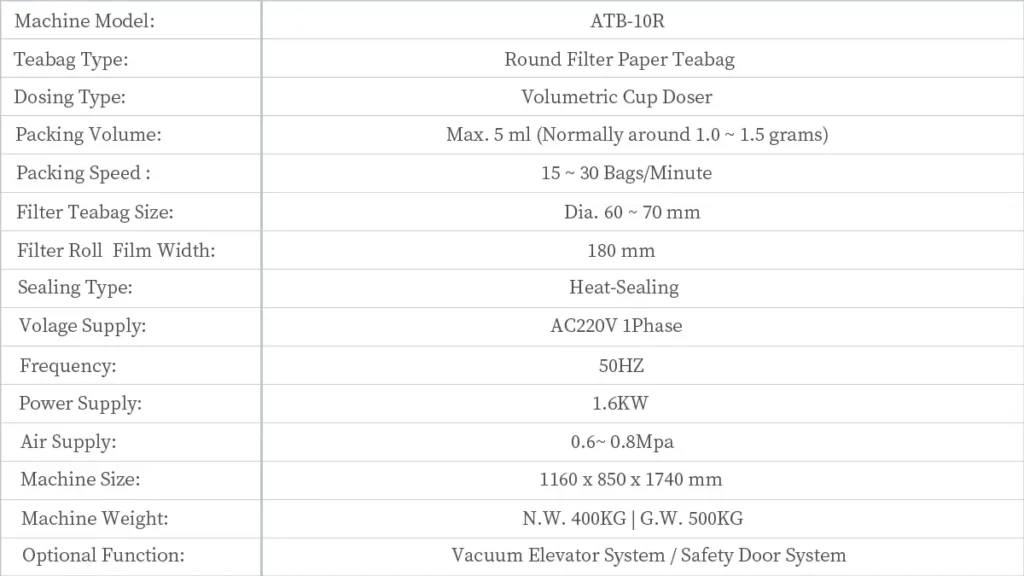

MODEL ATB-10R | TECHNICAL DATA

This round teabag machine adopts an integrated compact design style to realize the function of automatic round teabag packaging. By connecting with the volumetric cup doser system, it could support the users to produce 15 ~ 30 teabags per minute according to the tea product features. It could only produce the naked round-shaped teabag without thread, label, and outer foil sachet. The whole machine unit shall be packed into the export wooden case directly for seaway transportation. The users could charge electricity to run the machine directly when the case arrived at their workshop.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE TEABAG PACKING MACHINE

- This round teabag packing machine is suitable for packaging small granular materials in tea, coffee, food, medicine, etc. markets. It has the function of automatically completing bag making, measuring, filling, sealing, cutting, counting, etc. Advanced PLC microcomputer controller and step motor driver to control bag length positioning system are applied to ensure stable machine performance. All the material contacting parts are made of food-level stainless steel to ensure the sanitation and reliability of the product;

- The teabag machine could keep running with stable and large output. Most small enterprises prefer to buy and use it due to its reasonable price and small space occupation. The operating Flexem interface is a double language design which is simple and the workers can handle it easily after simple training. The market sources of packaging consumables and major spare parts are abundant which helps to reduce production costs;

- The whole packing machine frame and the material contacting parts all adopt the food-level stainless steel to meet the food production requirement. It only requires the heat-seal type filter paper film for production with simple operation. only one operator is needed for normal production and output product collecting. The waste film collecting system is equipped to facilitate the user’s daily production.

- With the pace of life growing faster and faster, more and more people choose the filter tea bag instead of the traditional way of brewing tea. It is easier to carry and brew no matter whether traveling or at the office. Meanwhile, the market need for good quality tea bag packing machines has grown up in recent years. Solution-Pack has focused on teabag packing machines for over 12 years with rich experience and market research and offers different types of tea bag packing machines to meet the market requirements;

- To better support the client with the project, we supply sample material testing services for the client who is a start-up on the tea bag machine project. Each client could deliver around 4 kg of sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange the machine to test the material and propose the most suitable inner and outer tea bag size for the client. In this way, it could better ensure the client gets the most accurate packaging data for their products. We could also supply the client with customized packaging materials.