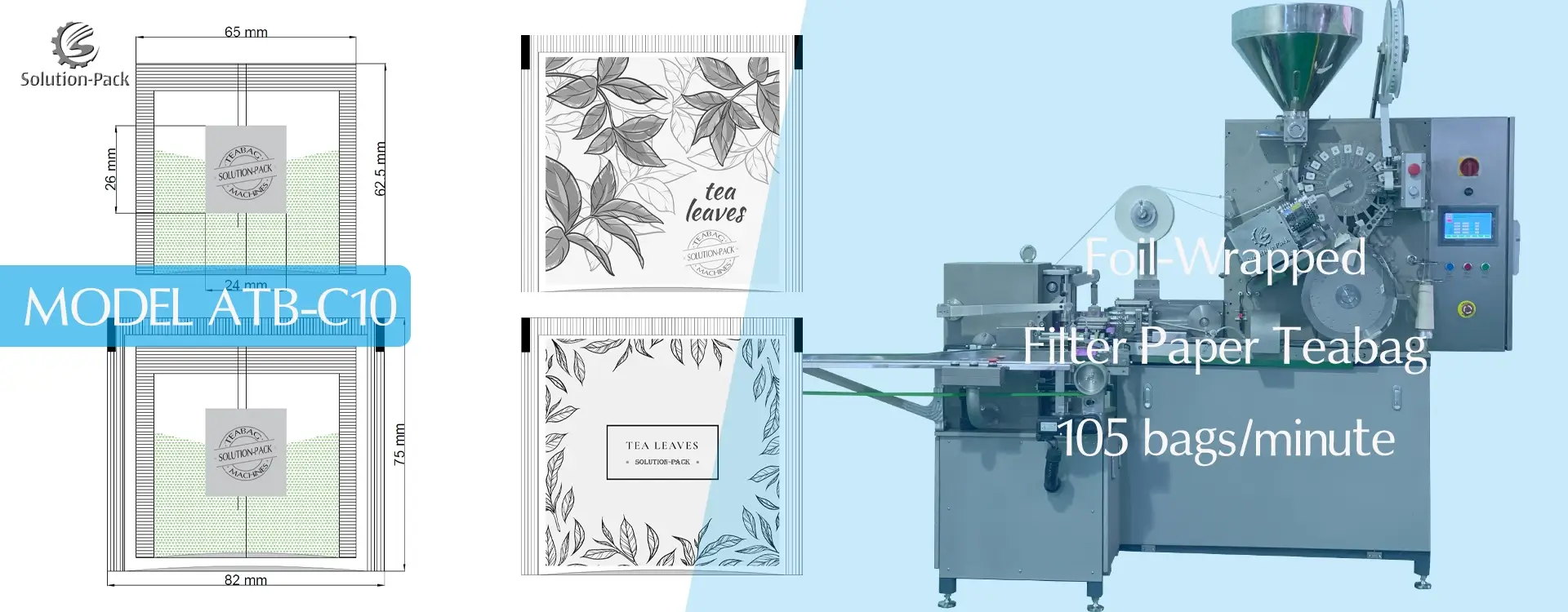

The ATB-C10 automatic foil-wrapped teabag packing machine unit is an updated machine model with foil outer sachet packaging functions. It could dose a maximum of 10 ml tea products of 20 meshes to 60 meshes or bulk non-viscidity granular materials, such as CTC black tea, green broken tea, and herbals into the bag. This teabag packaging machine focuses on producing single chamber filter teabag with thread and tag, then wrapping it into a foil envelope sachet automatically. Both the inner tea bag (65 x 62.5 mm) and the outer envelope sachet (75 x 82 mm) are of standard sizes for the international tea packaging market.

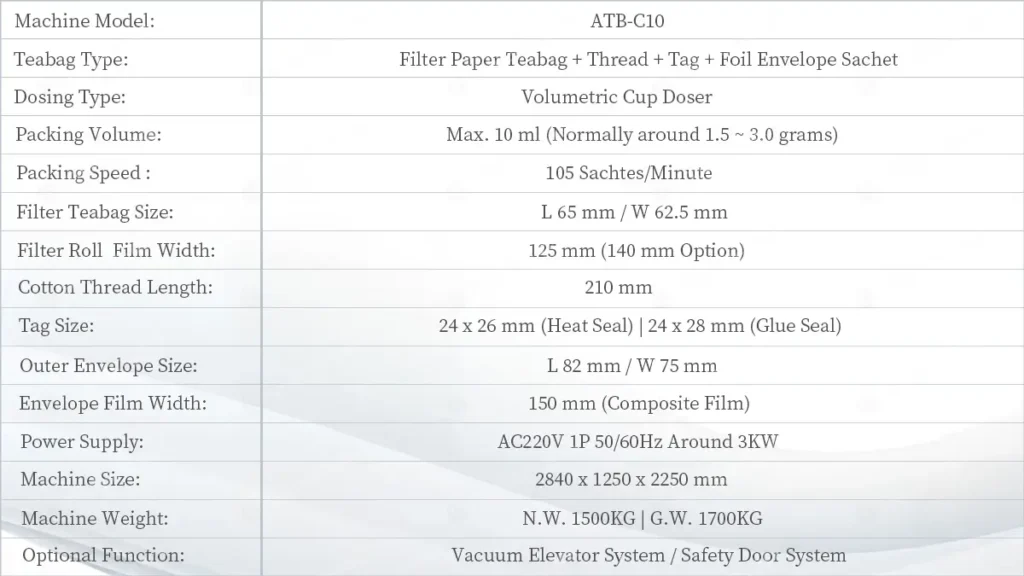

MODEL ATB-C10 | TECHNICAL DATA

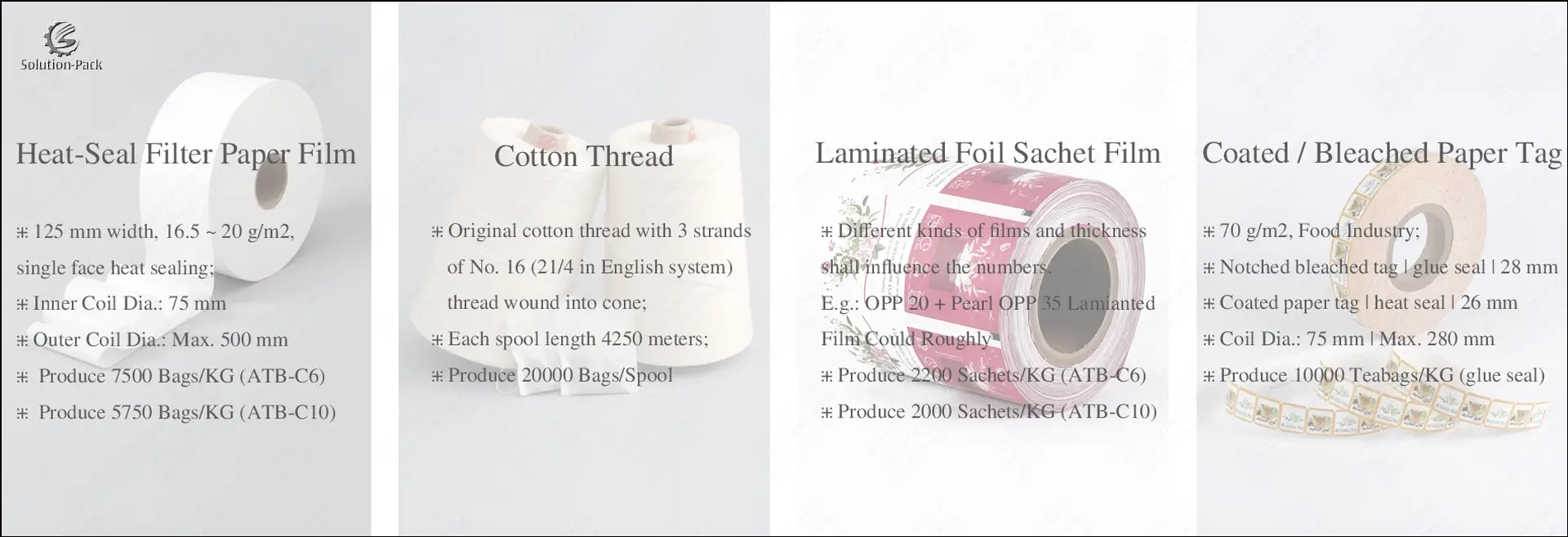

This foil-wrapped teabag packaging machine unit can produce standard teabag sizes: 65 x 62.5 mm (Filter Teabag with Thread and Tag); and 75 x 82 mm (Outer Foil Envelope Sachet); Normally the inner filter teabag can hold 2.5 ~ 3 Grams of CTC Black Tea. This teabag packaging machine requires 4 kinds of packaging materials: Filter Paper Film (Heat-Seal Type); Heat-Seal Type Tags; Cotton Thread; and Laminated Foil Outer Sachet Film Coil. According to the production needs, the vacuum elevator system with material level sensors and the transparent safety guard system with alarm function could be customized.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE TEABAG PACKING MACHINE

- This teabag packing machine model adopts intelligent Panasonic PLC control and operates on the Samkoon HMI interface easily. The whole machine frame and the material contacting parts are made of high-strength food-level stainless steel with a good appearance. Different kinds of sensor-detecting systems are equipped on this machine to detect jammed teabags, empty teabags, shortage of packaging materials, and tea materials. The transparent safety guard system is designed on this machine model to support a clear and safe production process;

- It focuses on packing foil envelope tea bags with a stable production speed of 105 sachets per minute. The standard teabag machine unit has designed the automatic counting system and the user could pre-set the counting numbers directly on the HMI. Normally, the operator could manually pick up the counted foil envelope teabags into the box directly. An automatic boxing system could also be chosen to realize full automation production;

- This machine unit adopts an integrated design style which is compact for installation. According to each factory’s production needs and market requirements, this teabag packing machine could also connect with the vacuum elevator system to elevate the tea product automatically with a material level sensor. An automatic weight checker and the rejecting device could be connected to check the output sachet weight to ensure the quality of the final product before packaging it into the box.

- The foil-wrapped teabags could prevent moisture and keep the fresh taste of the tea product. Thus, most of the tea factories choose to pack the filter teabag with thread & tags into the foil sachet to ensure a longer freshness date. What’s more, the foil-enveloped tea bags have a better appearance for marketing. Compared with traditional naked filter tea bag packing machine solution, this enveloped tea bag packing machine solution could help to save cost because there is no need to cellophane wrap the box after the tea bags are packed into it;

- To better support the client with the project, we supply sample material testing services for the client who is a start-up on the tea bag machine project. Each client could deliver around 4 kg of sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange for the machine to test the material and confirm if the standard tea bag sizes meet the customer’s products or not. In this way, it could better ensure the client gets the most accurate packaging data for their products. We could also supply the client with customized packaging materials.