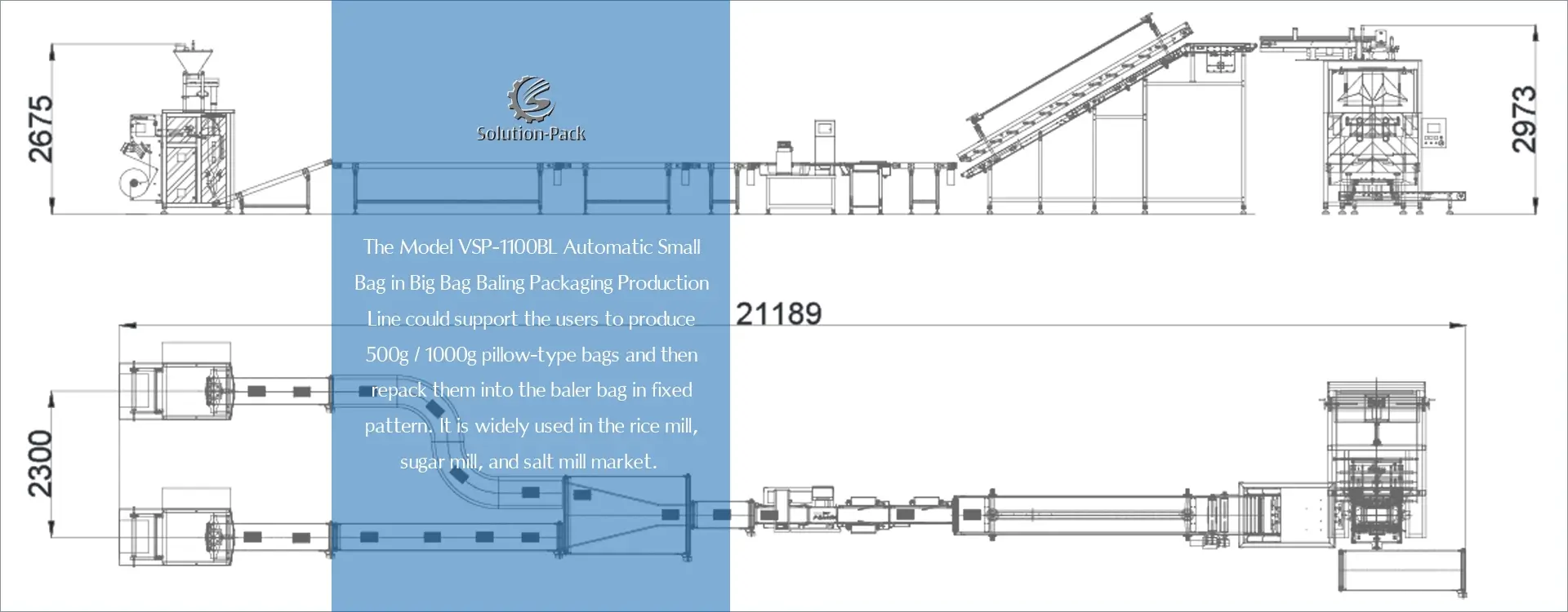

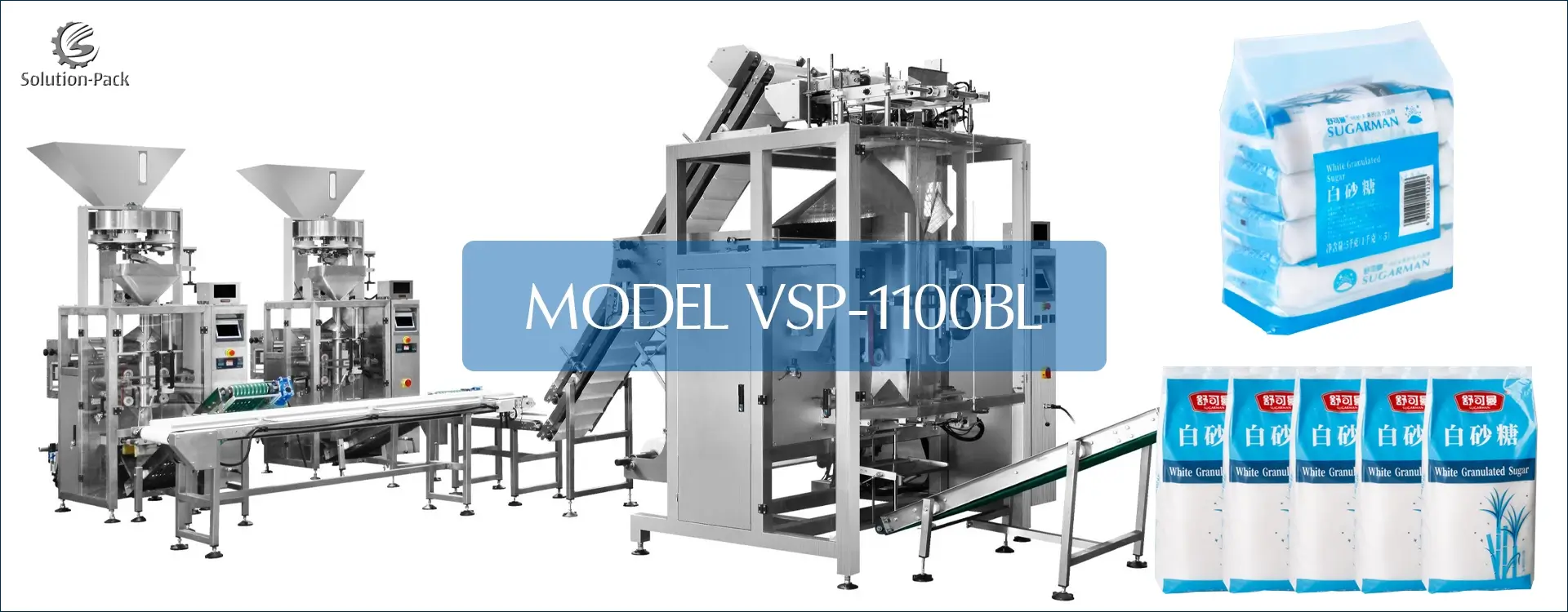

The VSP-1100BL automatic bag-in-bag baling packaging machine production line is the typical packing method for repacking the primary bags into the baler bag vertically. The whole production line is generally composed of two sets of VSP520C vertical packing machines, one set of baling machines, and the primary bag conveying arranging system. This solution could repack the primary bags in the baler bag in order according to the user’s requirements. Presently, this bag-in-bag baling machine production line is widely applied in refined salt, white sugar, refined sugar, and rice mill markets.

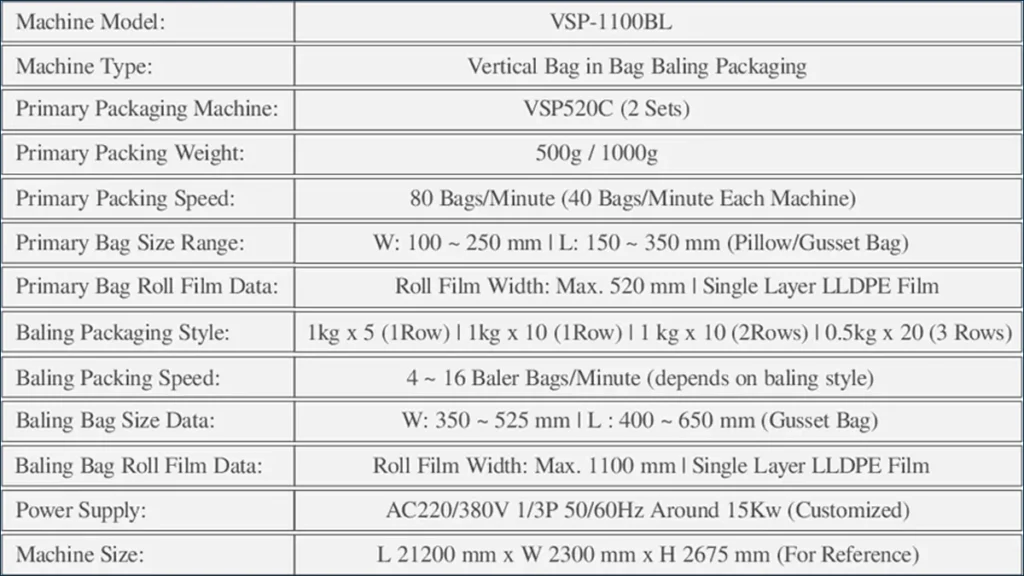

MODEL VSP-1100BL | TECHNICAL DATA

This type of small bag repacking into a baler bag packaging system is a typical packing solution in the white sugar, refined salt, and rill mill market. It has 4 baling packaging patterns for the users to choose from directly. These baling patterns are the most commonly used in the market. Both the primary bags and the baling bags shall adopt the single-layer LLDPE film for production with the advanced Ropex heat-sealing system. The baling machine could be extended to max. 1400mm roll film width depending on the users’ exact production requirements. The whole system layout design shall be customized to the users’ workshop to make full use of the available space.

SUBMIT HERE TO CONTACT US

TYPICAL VERTICAL PACKING MACHINE FEATURES

Intelligent Design

The entire vertical form fill seal packaging machine adopts a compact structure design for more stable working. It is more optimized for convenient operation. The whole machine frame and the material contact parts use the food level stainless steel to meet food production sanitary requirements. The surface of the steel is fully polished to ensure the best appearance and cleaning convenience. The safety door system uses a transparent Lexan board which allows the user to check the mechanical movements inside the machine easily.

Advanced Configuration

As one of the professional vertical form fill seal machine manufacturers, Solution-Pack offers high-standard configuration for the users with a pleasant user experience. We adopt the smart Siemens PLC control with a 10-inch colorful HMI interface for convenient operation. The other related pneumatic and electrical parts also adopt AirTac, SMC, Schneider, or equal brands to facilitate the user to source the spare parts easily from the local market. Meanwhile, the user could also choose to purchase them from us directly.

Customized Features

The standard packaging machine unit does not include the elevator system and products’ take-off conveyor system. Generally, we shall check the features of the client’s product features and then propose the most suitable elevator and conveyor system for them. Different materials and bag shapes have different features, unlike small vertical form fill seal machines, the VSP-1100BL vertical packaging machine solution needs to work with the client together to figure out the best combination for the exact production needs.

This bag-in-bag automatic packing machine solution is a customized integrated production line. The solution includes the primary bag packaging machine, the transitional conveyor line, and the baling system. The primary bag packing machine generally connects with the raw material silo with a material level sensor to realize a continuous production process. To ensure the best product quality, the automatic check weigher and metal detector with a rejecting system are always equipped to reject unqualified products. Meanwhile, this production line is mostly used to pack standard weights of 500g or 1000g for uniform materials.

The full system adopts a high-standard configuration to ensure the best running performance. Both the primary and the baling systems use Siemens PLC and HMI with customized programs. The other pneumatic and electrical parts all adopt internationally famous brands like SMC, AirTac, Schneider, Mettler Toledo, Sick, or equal brands. All the materials contacting parts are made of food-level stainless steel. The other parts are made of polished stainless steel or coated carbon steel with a better appearance. The volumetric cup doser system uses servo motor control which could adjust the volume easily.

This bag-in-bag baling packing machine production line is only suitable for LLDPE single-layer film packaging. To better ensure the sealing performance, the heat-sealing system for both the primary packaging machine and the baling packaging machine all adopts the Germany Ropex sealing control system. The LLDPE single-layer film has the key feature of being soft and extending, it could better protect the primary bags during the free-dropping process. The traditional laminated packaging material shall form sharp angels and it will be easy to overturn in the dropping action.

CHOOSE SOLUTION-PACK | FIND THE BEST BAG-IN-BAG BALING MACHINE SOLUTION

- We are one of the leading vertical forms fill seal machine manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. We provide professional before-sale consulting services for users to know more about the equipment and clarify all the details before supplying the formal quotation sheet for the user’s team. You will surely get the most suitable machine solution for your project if you choose to cooperate with us.

- We provide two types of after-sale service systems for the client under different conditions. If the user has a professional engineering team, we propose the online instructing installation service. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, if the user is for the first time to install the machine and without any knowledge of packaging machines, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.

This is an automatic weight check and reject machine unit that could connect with the packing machine to check the packaging weight and reject the unqualified bags to ensure the final product’s quality.