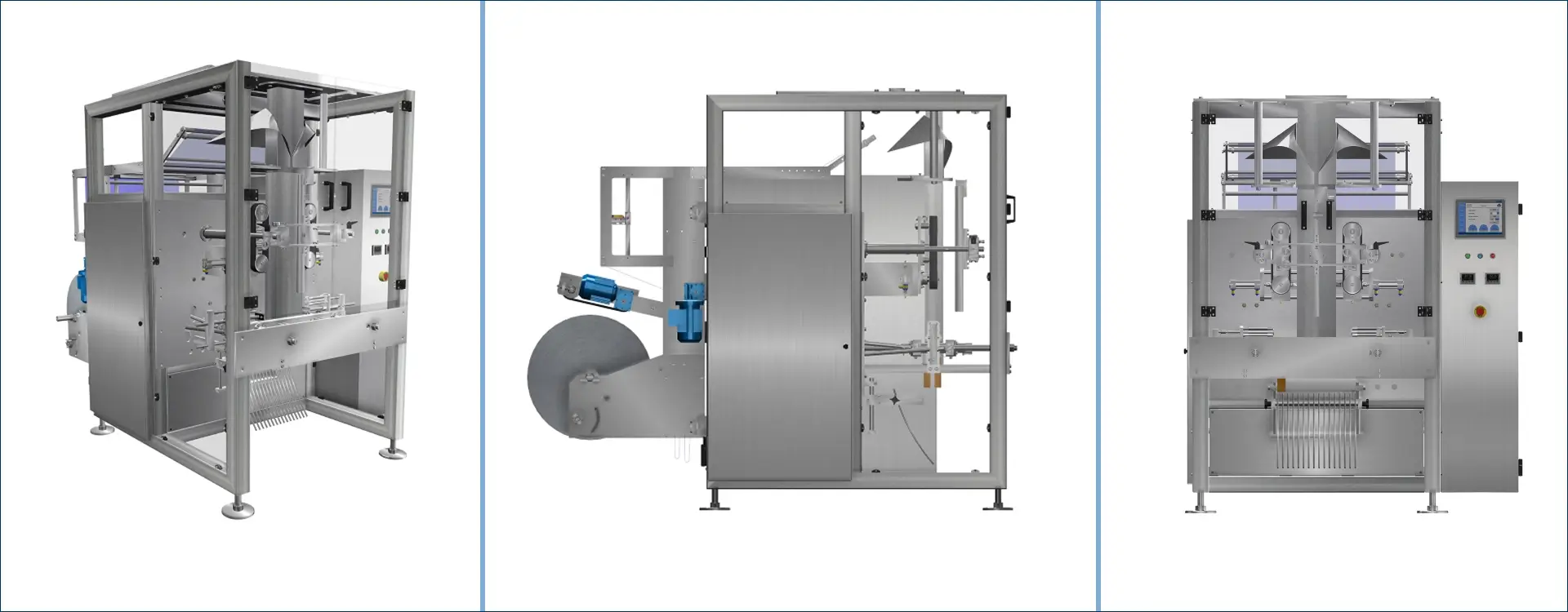

The model VSP630M automatic vertical form fill seal machine unit is one of the mature vertical packaging machine technologies. By connecting with the multi-head weighing filling machine and the bucket elevator system, this vertical packing machine unit could realize the function of automatic material elevating, product weighing filling, film pulling, date printing, bag forming, heat-sealing, cutting, and finished bag take-off. It could produce both pillow-type bags and gusset-type bags by changing the bag-forming collar. Presently, this system is widely applied in the market to pack materials like chips, snacks, nuts, beans, pet food, seeds, and grains.

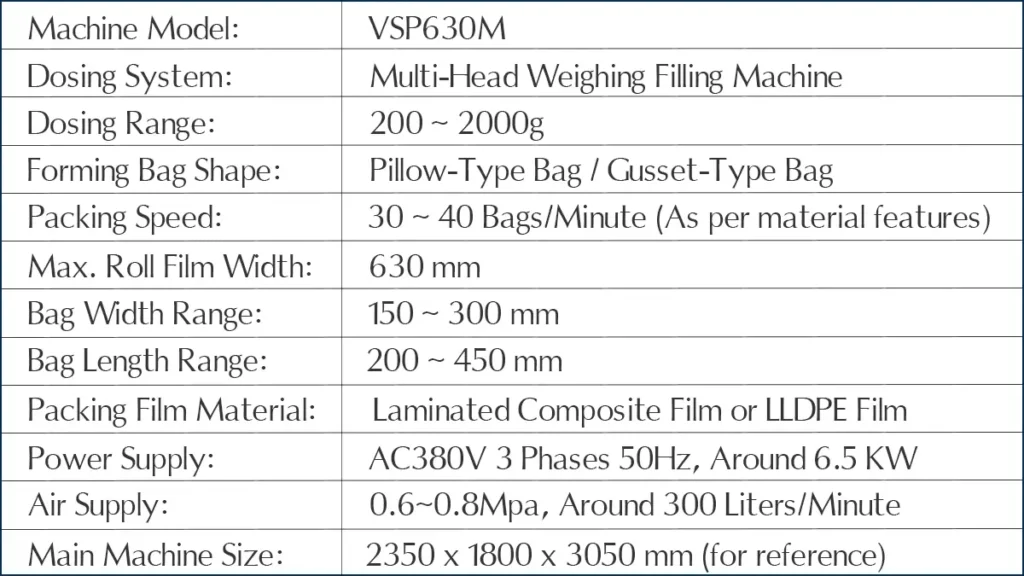

MODEL VSP630M | TECHNICAL DATA

This vertical packaging machine unit is the most popular equipment in the market for packing regular or irregular products into bags. The multi-heading weighing filling machine adopts computer control with an independent HMI interface for operation. The combination weighing method ensures that it has great weighing accuracy for irregular-shaped products or mixed products. Solution-Pack could support the users to connect several sets of packaging machine units with the carton box repacking production line or bag-in-bag secondary repacking production line.

SUBMIT HERE TO CONTACT US

TYPICAL VERTICAL PACKING MACHINE FEATURES

Intelligent Design

The entire vertical form fill seal packaging machine adopts a compact structure design for more stable working. It is more optimized for convenient operation. The whole machine frame and the material contact parts use the food level stainless steel to meet food production sanitary requirements. The surface of the steel is fully polished to ensure the best appearance and cleaning convenience. The safety door system uses a transparent Lexan board which allows the user to check the mechanical movements inside the machine easily.

Advanced Configuration

As one of the professional vertical form fill seal machine manufacturers, Solution-Pack offers high-standard configuration for the users with a pleasant user experience. We adopt the smart Siemens PLC control with a 10-inch colorful HMI interface for convenient operation. The other related pneumatic and electrical parts also adopt AirTac, SMC, Schneider, or equal brands to facilitate the user to source the spare parts easily from the local market. Meanwhile, the user could also choose to purchase them from us directly.

Customized Features

The standard packaging machine unit does not include the elevator system and products’ take-off conveyor system. Generally, we shall check the features of the client’s product features and then propose the most suitable elevator and conveyor system for them. Different materials and bag shapes have different features, unlike small vertical form fill seal machines, the VSP630M vertical packaging machine solution needs to work with the client together to figure out the best combination for the exact production needs.

The model VSP630M automatic vertical form fill seal packing machine mainly focuses on packaging 1 ~ 2.5 kg products with a stable production capacity of 30 ~ 40 bags per minute. It could be applied to pack both regular or irregular shape materials with high dosing accuracy. The production speed could be improved when the heads of the weighing machine increase. In this way, it could greatly support the user to improve production efficiency. It also saves labor costs compared with the manual or semi-automatic packaging method. What’s more, the high production capacity could ensure the user gains more orders for continuous production.

This vertical form fill seal machine unit uses food-level stainless steel for the whole machine frame and the material contacting parts. On the one hand, it could better ensure the food product safety requirements. On the other hand, it has anti-corrosion features to better extend the shelf time of the machine. Meanwhile, the vertical packaging machine follows the command from the PLC system to perform the sealing action which could output more neat, uniform, and beautiful bags compared with manual or semi-automatic packaging methods. What’s more, the linear weighing system adopts the famous brand load cell which could promise packaging accuracy to meet the market needs.

CHOOSE SOLUTION-PACK | FIND THE BEST VERTICAL PACKAGING MACHINE SOLUTION

- We are one of the leading vertical forms fill seal machine manufacturers from China with a rich experience of over 12 years in integrated packaging solution design and manufacturing. The VSP630M machine model supplied by us could perform both gusset bag packaging and pillow bag packaging by taking around 10 minutes to change the bag forming collar system. It allows the user to pack uniform granule materials at a stable production speed of 30 ~ 40 bags per minute according to the product’s features and additional function requirements. You will surely get the most suitable machine solution for your project if you choose to cooperate with us;

- We provide two types of after-sale service systems for the client under different conditions. If the user has a professional engineering team, we propose the online instructing installation service. We shall open the WeChat video online when the machine arrives at the client’s factory and then guide the user to install the machine unit and adjust all the parameters. However, if the user is for the first time to install the machine and without any knowledge of packaging machines, we shall arrange for our engineer to travel to the factory plant to make the installation and training work for the user. It depends on the user’s choice to conduct the work.

This is an automatic weight check and reject machine unit that could connect with the packing machine to check the packaging weight and reject the unqualified bags to ensure the final product’s quality.