The refined sugar packing machine solution that we shall introduce here focuses on packaging standard 500g and 1000g refined sugar products or white granule sugar products. It adopts the VSP520C model, VSP520M model, or VSP520L model vertical form fill seal machine to realize the production process. Generally, the final products could be packed into the center-seal pillow bag or gusset bag for market sale. According to the production needs, these vertical packaging machines could connect with the baling packing machine system or the secondary packing machine system to realize the repackaging process.

CHOOSE YOUR REFINED SUGAR PACKING MACHINE SOLUTIONS

KEY FEATURES OF VERTICAL FORM FILL SEAL PACKAGING SOLUTION

The vertical packaging machine solutions from Solution-Pack could realize the functions of automatic material dosing, film pulling, date printing, bag forming, material filling, (gusset forming), heat-sealing, and finished product output. The intelligent Z Type bucket elevator system could be equipped for continuous production or the user could connect the weighing machine hopper with the raw material silo directly. The whole packaging process only requires one operator to run the machine and change the film rolls when it runs out.

These white sugar packing machine solutions are of high-standard configuration. All the material contacting parts and the machine frame are made of food-level stainless steel to meet food production needs. The PLC control and HMI display interface all adopt the smart Siemens brand with good performance. The other electrical and pneumatic parts also use internationally famous brands like SMC, AirTac, Schneider, Omron, Mettler Toledo, Panasonic, etc. When the user adopts the LLDPE single-layer film for packaging production, we shall use the Germany Ropex impulse sealing system to better seal the bag with good strength.

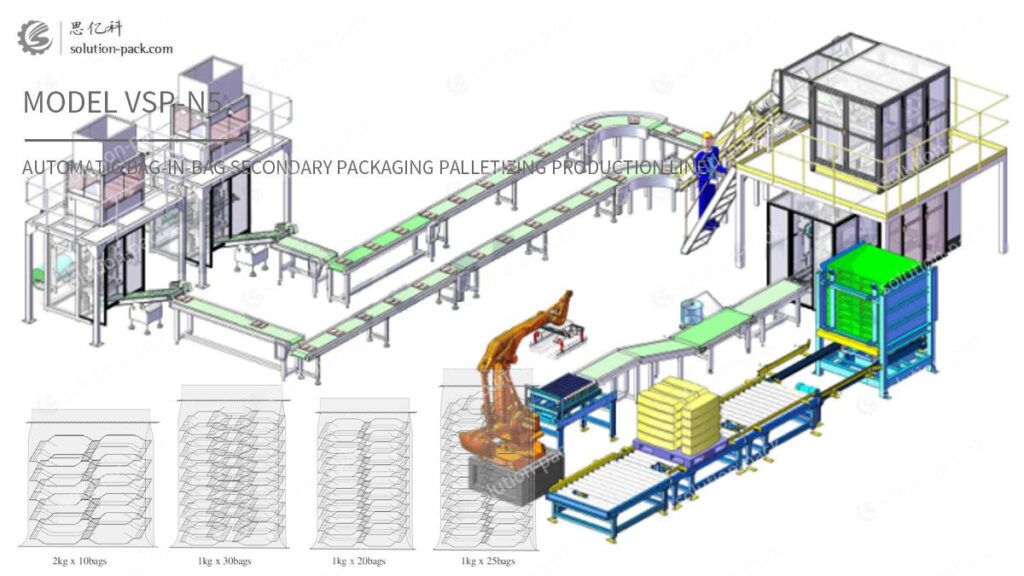

Solution-Pack offers customized granule sugar packaging machine systems for users according to specific production requirements. The standard vertical form fill seal machine unit could connect with different types of weighing dosing systems. It could produce a pillow-type bag or gusset-type bag by changing the forming tube and adding the gusset devices. Meanwhile, the machine solution could also connect with the checker weigher system, metal detector system, baling packing machine system, or secondary packing machine system to form a whole production line process.

FAQ ABOUT VERTICAL FORM FILL SEAL PACKAGING MACHINE

What are the different types of sugar packaging?

The sugar packaging is mainly divided into three parts: sugar sachet packing machine, sugar bag vertical packing machine, granule sugar bagging machine, sugar bag-in-bag baling machine, and sugar bag-in-bag secondary packing machine. The white sugar stick packing machine is used to pack 5 ~ 15 grams of sugar stick sachet. The sugar bag vertical packing machine is used to pack 500 ~ 2000g pillow-type or gusset-type bags. The granule sugar bagging machine is used to pack 25 ~ 50kg of sugar into the pp woven sacks. The sugar bag-in-bag baling machine is used to pack the primary sugar bag of 500g or 1000g into the baler bags. The sugar bag-in-bag secondary packing machine is used to pack the primary sugar bag into the pp woven sacks.

How to select the sugar packing machine for production?

Since there are different kinds of sugar packing machines for options. The user needs to clarify the specific production requirements first and then follow the guidance from Solution-Pack to choose the correct packaging machine solutions for production.

BENEFITS OF THE WHITE SUGAR VERTICAL PACKAGING SOLUTIONS

1. As we all know traditional manual granule sugar packaging method is time-consuming and more labor-intensive. With the continuous development of machine technology, the emergence of automatic sugar-packing machines changed the world packaging market. It not only effectively saves time, but also saves a portion of pressure, and allows various companies to develop in the process of slowly narrowing the gap, it also encourages the development of the entire enterprise.

2. The manual sugar packaging makes it difficult to avoid contact between people and the products due to manual participation, which may contaminate products and make production quality difficult to meet the GMP requirements. However, the fully automatic sugar packing machines from feeding to finished products outputting are fully automated processes without manual participation, and this packaging production line could reduce bacterial contamination in the packaging process which provides a good guarantee for enterprises.

3. Generally, the vertical sugar packing machine solution could produce a standard 40 bags per minute. Compared with the traditional manual production process, it has increased the production capacity a lot. And it could support the user to gain more orders for continuous production to enlarge the factory scale. What’s more, the primary sugar packing system could connect with different kinds of ancillary equipment to form a whole automated production process.