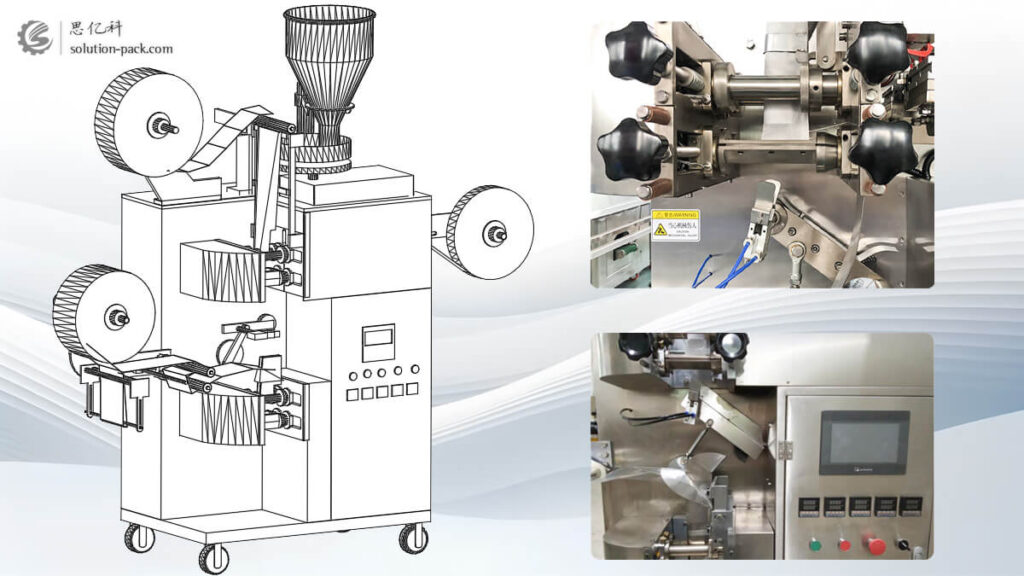

ATB-S1 automatic filter tea bag packing machine unit is a basic machine model for packing tea products into filter bags. The machine is composed of a cup dosing weighing filling system, filter paper tea bag forming sealing system, cotton thread feeding system, tag paper feeding sealing system, envelop bag forming sealing system, and finished products out-put conveyor system. The machine unit could be applied to different kinds of tea product markets. Examples are herbal tea, granule tea, healthy tea, pharmacy tea, ground coffee, grind tea powder, and other small particle products.

TEABAG PACKING MACHINE TECHNICAL DATA

Machine Model: ATB-S1

Packing Volume: 1 ~ 5 ml (Depends on product features.)

Packing Speed: 30 ~ 40 Tea Bags per Minute

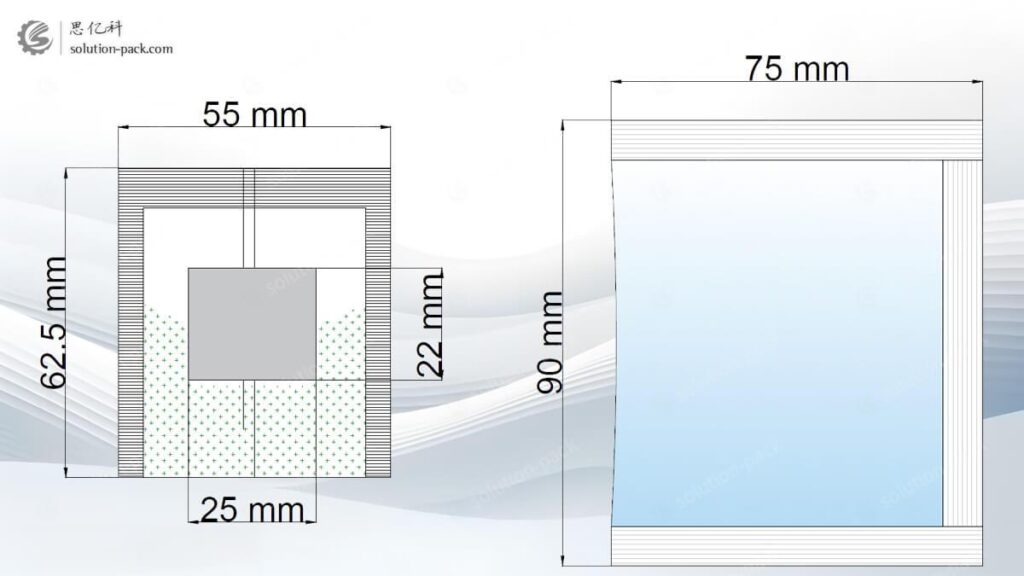

Forming Bag Style: Filter Tea Bag with/without Thread and tag (Single Chamber Type)

Filter Tea Bag Size: L 50 ~ 70 mm | W 40 ~ 80 mm

Cotton Thread Length: 155 mm

Heat Seal Tag Size: L 20 ~ 24 mm | W 40 ~ 55 mm

Packaging Film: Heat-Seal Type Filter Paper Film

Outer Foil Sachet Size: L 70 ~ 120 mm | W 60 ~ 90 mm

Outer Sachet Film: Laminated Composite Film

Machine Size: L 1250 mm x W 700 mm x H 1800 mm

Power Supply: AC230V 50/60Hz Single Phase Around 3.7Kw

Machine Weight: Around 500 Kg

TYPICAL FEATURES OF THE FILTER TEA BAG PACKING MACHINE

ATB-S1 automatic economic filter tea bag packing machine model is the most applicable machine solution for start-ups or medium companies in the tea market. The machine is designed as a whole unit, and the user can choose which function they need by just adding the packaging materials to the fixed station. Multiple teabag types ensure that the user can easily adjust the package type to meet their market needs.

The machine unit is now widely applied to pack black CTC tea, grind herbal tea, grind leaf tea, and some other tea products that have already been processed into small particles. Solution-Pack provides customized material testing services for start-up companies who do not have a clear idea about the tea bag size. You could deliver the packing tea material to our factory and we shall use the machine to run with your products and then propose the best tea bag size for your products.

This tea bag packing machine is a multi-functional machine unit. It could realize the package of 4 different kinds of patterns. (Naked Filter Tea Bag / Filter Tea Bag + String + Tag / Naked Filter Tea Bag + Outer Envelop Sachet / Filter Tea Bag + String + Tag + Outer Envelop Sachet.) The client could choose the function that they need directly through feed or take down the packaging material directly.

The ATB-S1 automatic filter tea bag packing machine unit works for packaging 20 ~ 60 meshes of broken tea leaves or granule tea products. The user could choose to pack a filter tea bag with or without thread and tag, and the outer sachet function is also optional for the user. This teabag packing machine could produce around 30 ~ 45 teabags per minute according to the product features. This teabag packing machine unit is equipped with universal wheels to facilitate the user in movement and daily maintenance. The whole machine frame and material contact parts are all made of food-level stainless steel. The ATB-S1 tea bag machine is compact in size which shall be suitable for most small factories.

Choose Solution-Pack, Get Smart & Easy Tea Bag Packing Machine Solution | One Station Service

The ATB-S1 model automatic filter tea bag packing machine unit adopts Delta PLC control with Delta HMI Interface for the user to operate easily. The main motor adopts the TPG brand to ensure stable running performance. And Schneider solid relay, as well as Mitsubishi step motor, are applied for the system. Solution-Pack focuses on providing high-quality filter tea bag packing machines for the market. The extremely stable performance is what we could assure the user.

We also supply sample material testing services for the client who is a start-up on the tea bag machine project. Each client could deliver around 2KG sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange the machine to test the material and propose the most suitable inner and outer tea bag size for the client. In this way, it could better ensure the client gets the most accurate packaging data for their products.

If the user feels confused about choosing the packaging materials, Solution-Pack could also supply the client with customized packaging materials like Filter Paper / Cotton Thread / Paper Tag (Heat Seal Type). We could also support clients in counting out the estimated amount of packaging materials that they should use in one-year production when all the tea bag sizes are confirmed ready.