The ATB-S120 automatic naked tea bag packing machine unit is an electromechanical integration of tea bag packing machines for pharmaceutical, health care, food, and other industries. It can pack 20 meshes to 60 meshes or bulk non-viscidity granular materials, such as CTC black tea, green broken tea, and herbals into the bag. As for many medium-size tea production factories, having one set of high-speed tea bag packing machines shall ensure them a better chance to open the market and create more profit.

Technical Data | Naked Tea Bag Packing Machine

Machine Model: ATB-S120

Packing Volume: Max. 6 ml (Normally around 2 grams)

Packaging Material: Filter Paper Film (Heat-Seal Type)

Tea Bag Type: Naked Filter Teabag with Thread and Tag

Packaging Film Width: 125 mm

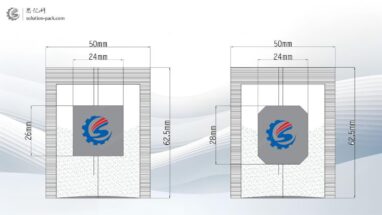

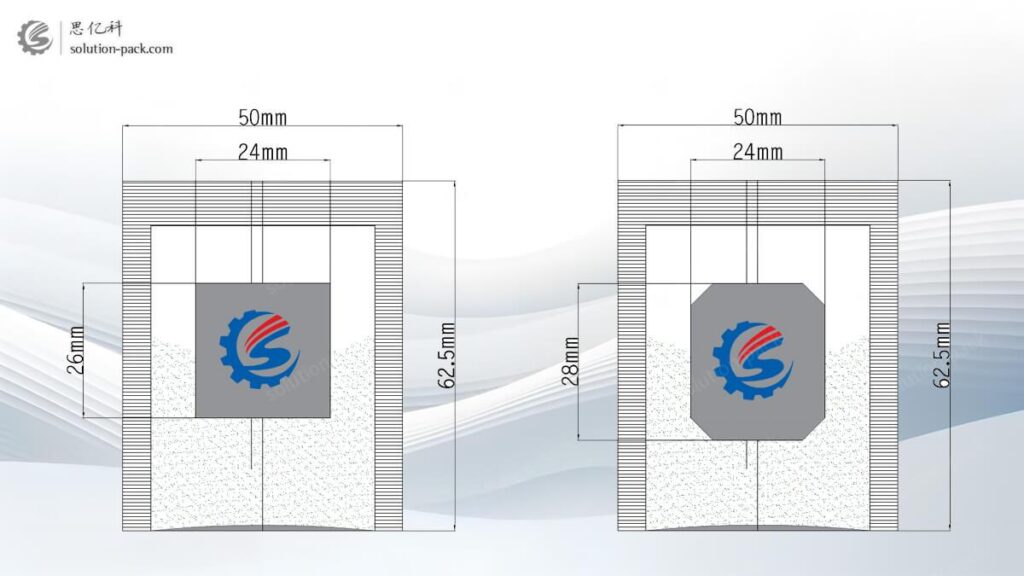

Filter Paper Tea Bag Size: 50 x 62.5 mm

Thread Length: 210 mm

Tag Size: 24 x 28 mm (Notched Glue Seal Type)

Packing Speed: 120 Teabags/Minute

Power Supply: AC220V 1Phase 50/60Hz 1.5Kw

Machine Size: 1700mm x 800mm x 2000mm

Group Boxing Options: a. 10’s | b. 25’s/50’s/100’s | c. 20’s/40’s | d. 30’s/60’s

Optional Function: Heat-Seal Tag System; Vacuum Elevator System; Hopper Stirring System

TYPICAL FEATURES OF THE NAKED FILTER TEA BAG PACKING MACHINE

This filter tea bag packing machine unit could realize quantitative material dosing, film cutting, cotton thread, adhesive labels, bag sealing, automatic counting, and other functions of a high-speed packing machine. There is no envelope function for this machine unit, but we improved the counting output and grouped the tea bags into a paper box which could save cost and be more efficient. This tea bag packing machine unit could pack standard teabag size (50 x 62.5mm) at the speed of 120 tea bags per minute.

The tea bag packing machine adopts an integrated design style with a compact size and ensures low spare parts costs and maintenance costs. The machine frame is made of painted carbon steel and the material contacting parts are made of food-level stainless steel to meet CE and GMP requirements. It could also connect with the automatic vacuum elevator system with a material level sensor to ensure that customer could feed material easily and saves material waste.

Standard Filter Paper Tea Bag Size

The ATB-S120 filter tea bag packing machine unit produces standard filter teabags with thread and tag with 125 mm filter paper film or 140mm filter paper film. The tea bag size is standard 50 x 62.5 mm. This tea bag packing machine unit requires three types of packaging materials: heat-seal type filter paper film, cotton thread, and notched tags. According to the user’s production needs, the heating-sealing tag system could also be added.

CHOOSE SOLUTION-PACK, GET INTELLIGENT FILTER TEA BAG PACKING SOLUTION | ONE STATION SERVICE

With the pace of life growing faster and faster, more and more people choose the filter tea bag instead of the traditional way of brewing tea. It is easier to carry and brew no matter whether traveling or at the office. Meanwhile, the market need for good quality tea bag packing machines has grown up in recent years. Solution-Pack has focused on teabag packing machines for over 12 years with rich experience and market research and offers different types of tea bag packing machines to meet the market requirements.

To better support the client with the project, we supply sample material testing services for the client who is a start-up on the tea bag machine project. Each client could deliver around 4 kg of sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange the machine to test the material and propose the most suitable inner and outer tea bag size for the client. In this way, it could better ensure the client gets the most accurate packaging data for their products. We could also supply the client with customized packaging materials.