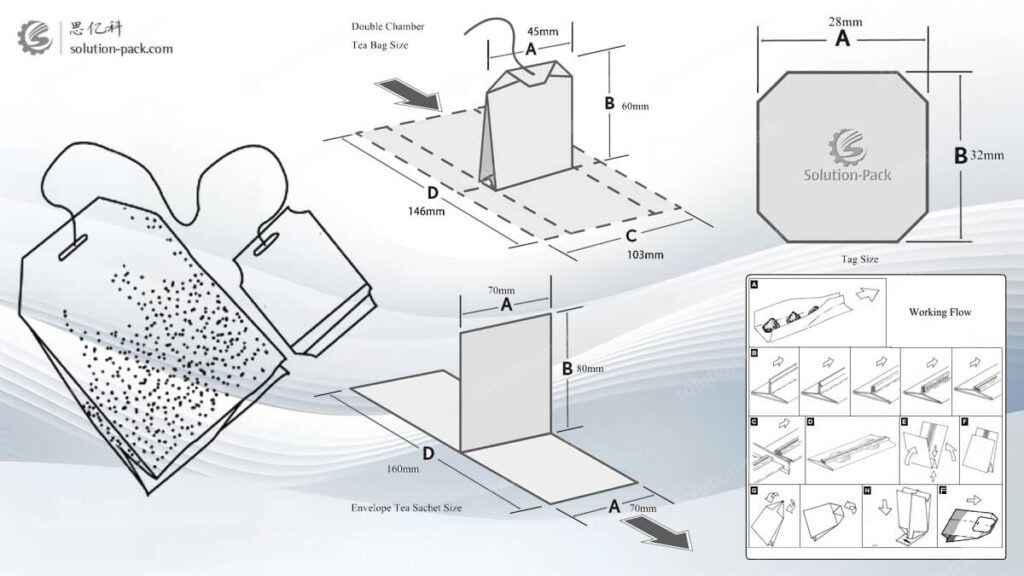

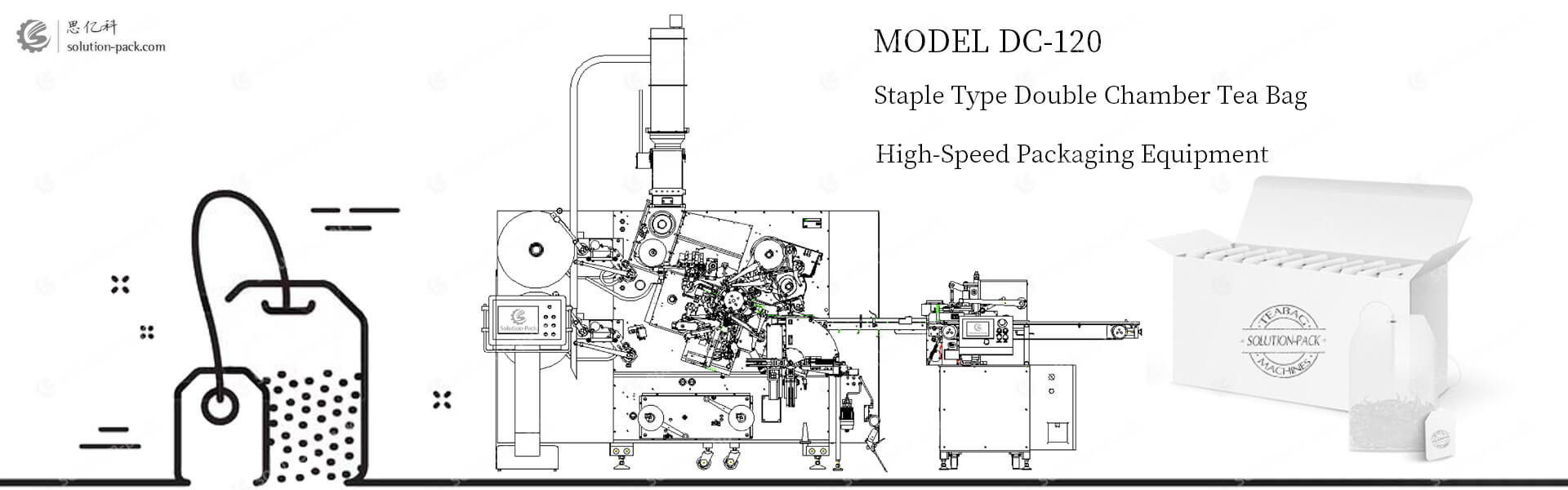

Brief Introduction | Double Chamber Tea Bag Packing Machine

The DC-120 model double chamber tea bag packing machine unit is a staple-type filter double chamber tea bag machine. It could produce staple-type double-chamber filter tea bags with thread and tag by cold-seal style. This machine unit could perform the function of automatic tea bag cold seal form, and complete the linking-up of the hard tag, thread, and the tea bag with the staple. This filter teabag packing machine unit is widely applied in medicine, health, and other industries for 20 ~ 60 mesh materials or non-viscosity granule products like CTC Black Tea, Green Broken Tea, Herbals, Health Tea, etc.

TYPICAL FEATURES OF THE DOUBLE CHAMBER TEA BAG MACHINE

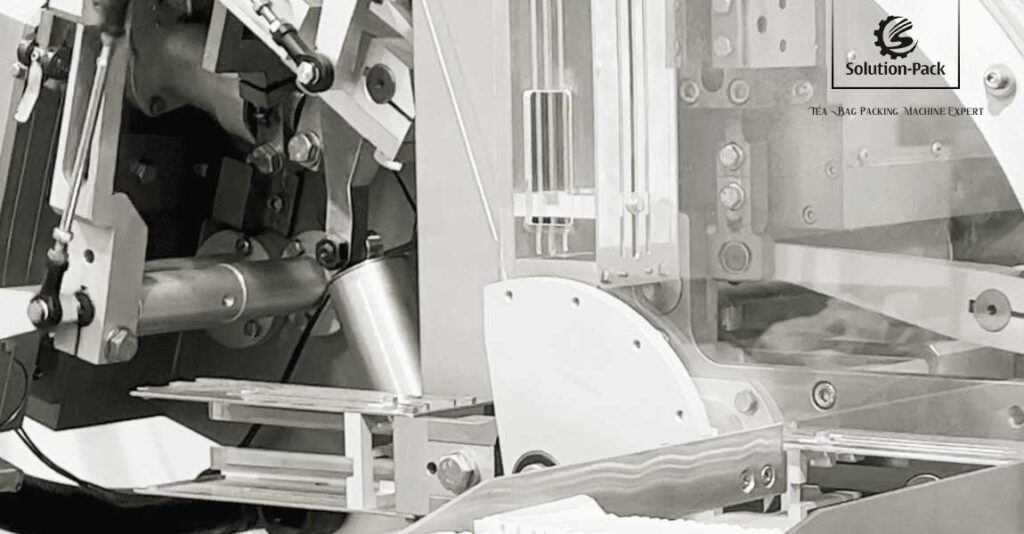

DC-120 double chamber tea bag packing machine unit is controlled by the Mitsubishi PLC system and all the operations can be done on the intelligent Weinview HMI directly to ensure the best user experience. And all the electrical and pneumatic spare parts adopt international well-known brands to facilitate the client source from the local market easily. An advanced issue diagnosis system is equipped. When the issue occurs, the machine shall stop immediately and reflect on the HMI. The operator could check the issue point and solve it more easily to save time and improve production efficiency. Necessary protection measures, such as short circuit protection, overloading protection, creepage protection, etc. also applied on the machine unit;

This double chamber tea bag packing machine unit is fully covered with the Lexan Transparent safety door system with a proximity switch. Once the door opens during production, the machine shall stop. And client could check all the working processes through the door easily. An automatic vacuum elevator system is equipped on the hopper with a material level sensor to ensure continuous production. Two emergency stop buttons have been designed to ensure the client can stop the machine immediately once any problem occurs;

The square marks on the tag paper and sachet film are identified to keep the traction and cutting of fixed length with high accuracy. The whole machine unit only requires one operator which greatly saves labor costs and creates huge profits for the client. The quantity of the counting numbers could be set on the HMI of the ATB-X machine freely to meet each client’s requirement for boxing.

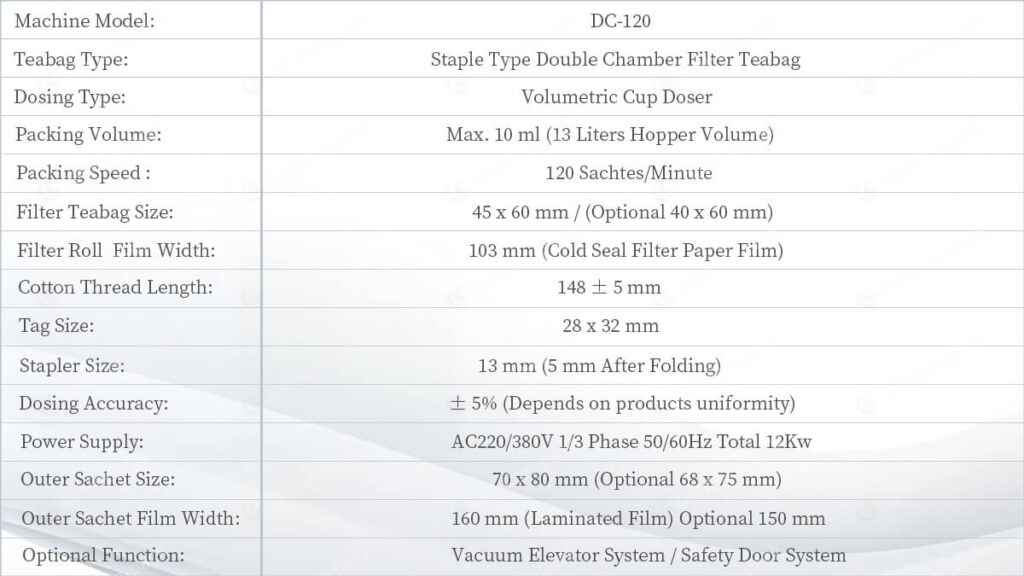

Standard Double Chamber Tea Bag Size Design

This staple-type double-chamber teabag packing machine requires five kinds of packaging materials: Cold Seal Filter Paper Film, Hard Tag, Cotton Thread, Aluminum Wires, and Laminated Outer Sachet Film. This teabag packing machine adopts an integrated design style with all functions focused on one machine unit to save installation space for the user. Other optional functions could be customized as per production needs.

Choose Solution-Pack, Get Intelligent Double Chamber Tea Bag Packing Machine Solution | One-Station Service

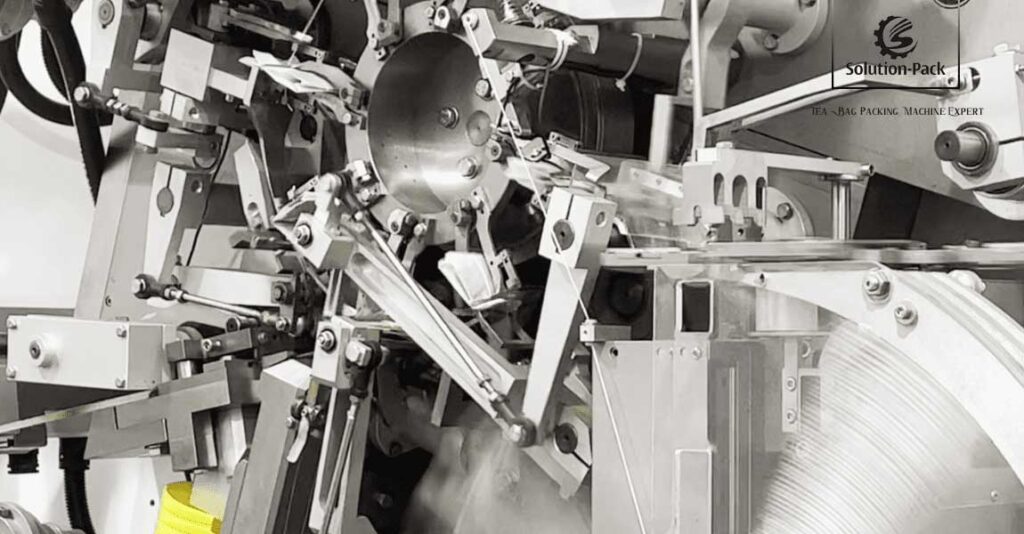

The filter double chamber teabags are the most popular tea bags in the world. Different factories may produce the double chamber teabag with some differences. Some factories produced cotton thread knotted type double chamber teabags, and some others produced staple-type double chamber teabags. The machine that makes these teabags are different also. Solution-Pack focuses on Staple-Type Double Chamber Tea Bag packing machine manufacturing. This machine unit could perform a stable running speed of 120 teabags per minute for the standard market.

To better keep the fresh taste of the tea, most of the tea factories choose to pack the filter teabag with thread & tags into the foil sachet to ensure a longer freshness date. What’s more, the foil-enveloped double chamber tea bags have a better appearance for marketing. Compared with traditional naked filter tea bag packing machine solution, this enveloped tea bag packing machine solution could help to save cost because there is no need to cellophane wrap the box after the tea bags are packed into it.