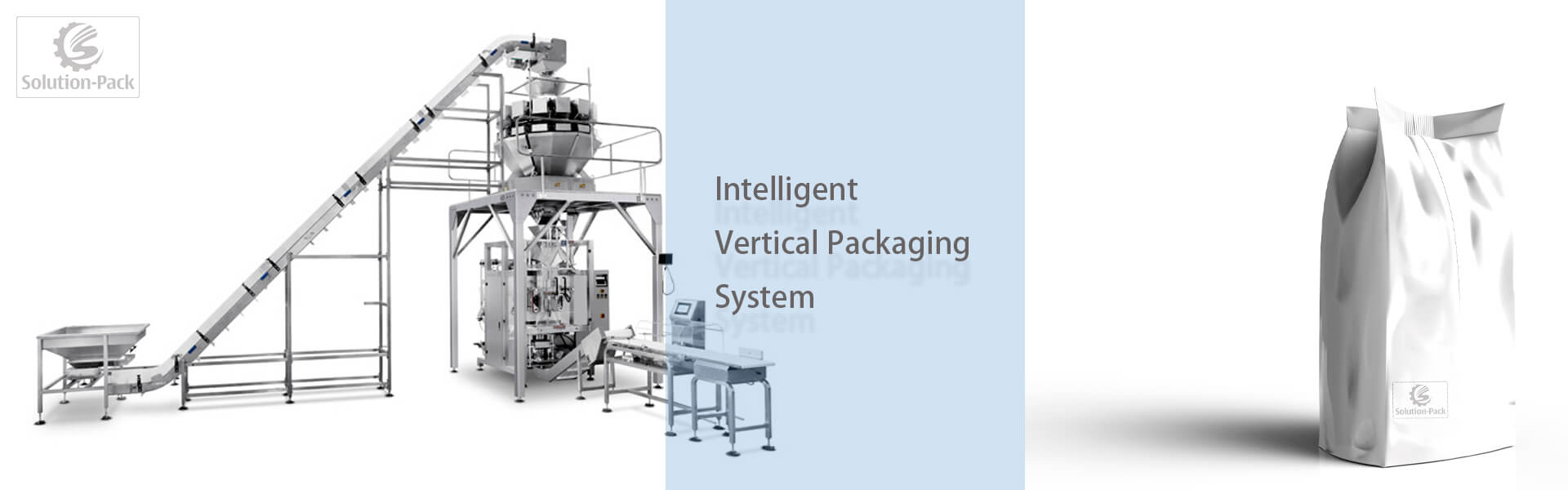

Solution-Pack is one of the leading integrated vertical packaging system providers located in the middle part of China. Instead of supplying the single vertical form fill seal machine unit, we focus on providing full sets of vertical packaging machine systems to support the user with a one-stop station service. All the functions of the packaging system are fully customized to each user’s specific requirements and production needs. The applicability of the solution is what we pursue to supply users to ensure the best running performance. Presently, these industrial packaging solutions are widely applied in food, grains, seeds, snacks, nuts, tea drinks, pet food, medicine, and the chemical market with customized solution designs.

CHOOSE YOUR VERTICAL PACKAGING SYSTEM

VERTICAL PACKAGING SOLUTION CHARACTERISTICS

Improving Production Efficiency

The vertical packing system adopts a fully customized design which could support the user to produce the pillow-shape or side-gusset shape bags with a stable high running speed. Compared with the traditional way of manual packaging, it shall help the user to improve production efficiency and save labor costs. And one packaging system only requires one technician to operate the machine and do the daily maintenance work. Meanwhile, the vertical form fill seal packaging machine system shall help the user build up a safe production environment to meet the market needs.

High-Standard Configuration

As one of the vertical form fill seal machine manufacturers, quality is the first point that we promise to the user. The whole machine frame adopts a polished steel surface with a good appearance. The packaging machine solution adopts internationally famous brand pneumatic and electrical parts to ensure working performance. The PLC control and HMI interface adopt the Siemens brand. The other pneumatic and electrical parts adopt Schneider, SMC, AirTac, Omron, or equal brands to facilitate the user to source spare parts easily from the local market. And the user could also get from us directly.

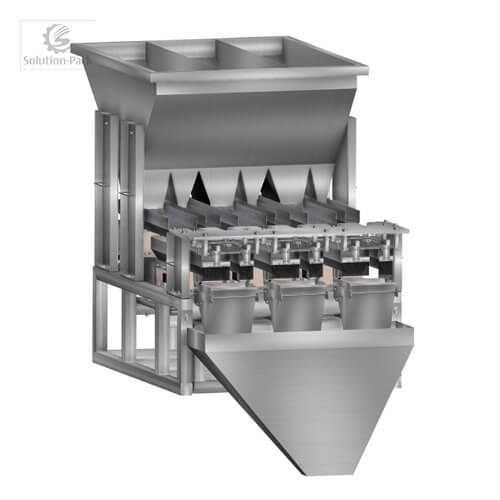

OPTIONAL DOSING FILLING SYSTEMS

The vertical form fill seal machine unit could connect with different kinds of dosing filling systems to realize the applicability of packaging different features of products. The auger screw doser is mainly used to pack non-free-flow powder material. The cup doser could be applied to pack uniform granules or particle products. The linear head weighing machine is used for packaging granule, leaf, or particle products, and the multi-head weighing system is used for packaging regular or irregular products with high dosing accuracy. What kinds of the dosing system should be combined with the vertical packing machine is decided by the products that the user needs to produce.

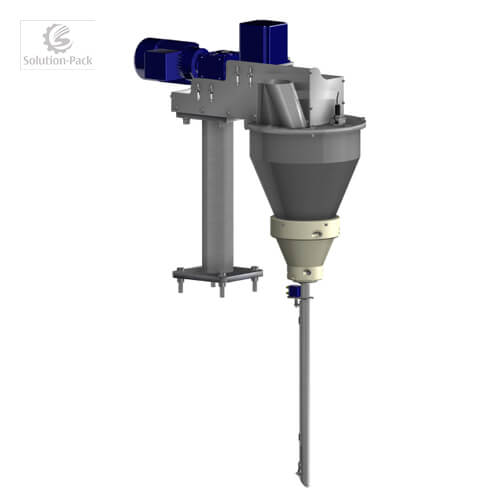

OPTIONAL ELEVATING SYSTEMS

The vertical form fill seal packaging machine unit normally needs to connect with a suitable elevating system to keep the material level in the dosing machine hopper. It only requires a single from the dosing hopper to control the start and stop functions. The typical elevator systems in the market are Z Type Bucket Elevator, Auger Screw Selvator, Bucket Elevator, and Vacuum Elevator. Each elevator has its own specific function to meet the elevating material features.