The VSP-1100BL automatic bag-in-bag baling packaging machine production line is the typical packing method for repacking the primary bags into the baler bag vertically. The whole production line is generally composed of two sets of VSP520C vertical packing machines, one set of baling machines, and the primary bag conveying arranging system. This solution could repack the primary bags in the baler bag in order according to the user’s requirements. Presently, this bag-in-bag baling machine production line is widely applied in refined salt, white sugar, refined sugar, and rice mill market.

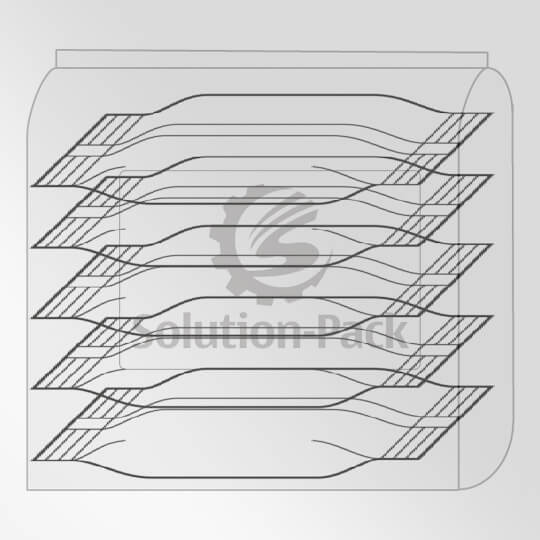

Baling Packaging Machine Technical Data Sheet

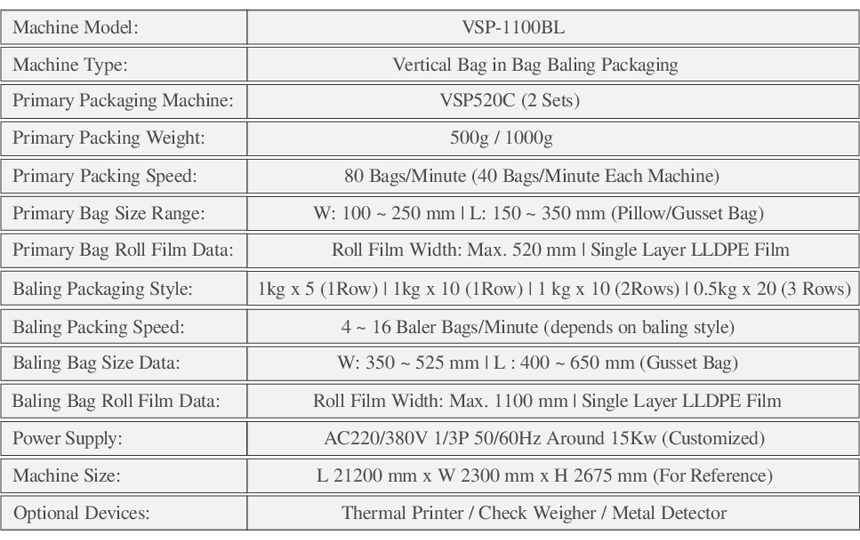

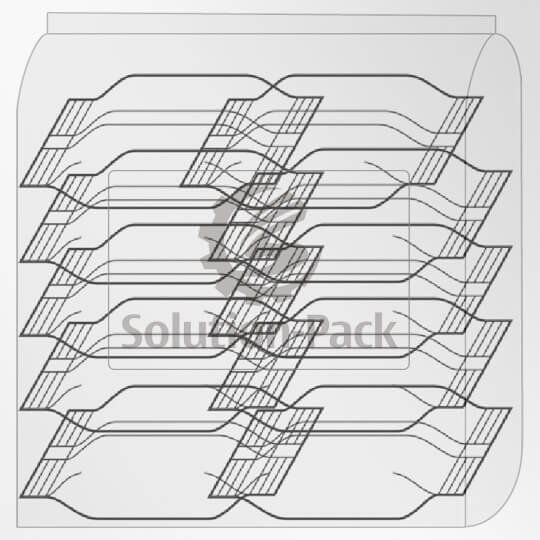

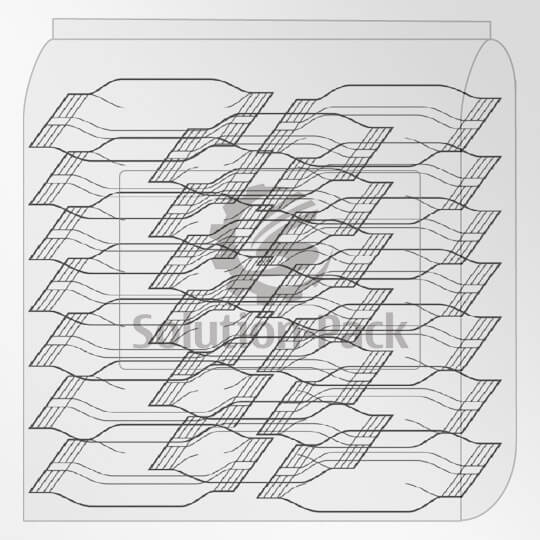

Customized Baling Packing Style

Key Features of The Baling Packing Machine Production Line

This bag-in-bag automatic packing machine solution is a customized integrated production line. The solution includes the primary bag packaging machine, the transitional conveyor line, and the baling system. The primary bag packing machine generally connects with the raw material silo with a material level sensor to realize a continuous production process. In order to ensure the best product quality, the automatic check weigher and metal detector with rejecting system are always equipped to reject unqualified products. Meanwhile, this production line is mostly used to pack standard weights of 500g or 1000g for uniform materials.

The full system adopts a high-standard configuration to ensure the best running performance. Both the primary and the baling system use Siemens PLC and HMI with customized programs. The other pneumatic and electrical parts all adopt internationally famous brands like SMC, AirTac, Schneider, Mettler Toledo, Sick, or equal brand. All the materials contacting parts are made of food-level stainless steel. The other parts are made of polished stainless steel or coated carbon steel with a better appearance. The volumetric cup doser system uses servo motor control which could adjust the volume easily.

This bag-in-bag baling packing machine production line is only suitable for LLDPE single-layer film packaging. To better ensure the sealing performance, the heat-sealing system for both the primary packaging machine and the baling packaging machine all adopts Germany Ropex sealing control system. The LLDPE single-layer film has the key feature of being soft and extending, it could better protect the primary bags during the free-dropping process. The traditional laminated packaging material shall form sharp angels and it will be easy to overturn in the dropping action.

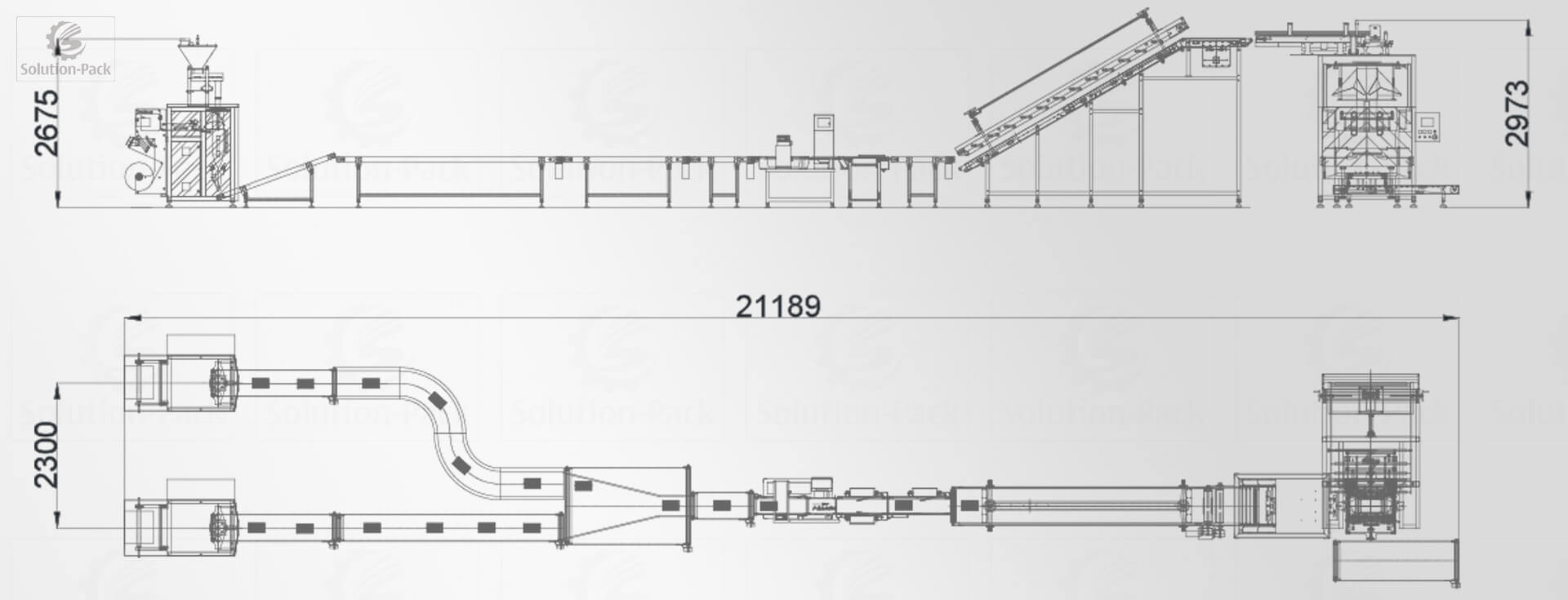

Reference Bag-In-Bag Repacking Machine Layout Design

FAQ About The Bag-In-Bag Packing Machine

WHAT’S THE PRICE OF THE REPACKING MACHINE PRODUCTION LINE?

This bag-in-bag repacking production line is fully customized to the user’s requirements. Unlike the standard packing machine solution, this type of system does not have a standard price reference. Solution-Pack shall support analyzing the project for the user and then provide a customized layout design for confirmation before offering a formal quotation sheet for the user’s company.

HOW DOES THE BAG-IN-BAG REPACKING MACHINE LINE WORK?

This production line shall start from primary bag packaging. The VSP-520C vertical packing machine shall produce standard primary bags and then arrange them in order before filling them into the baler bag. The baling machine shall wrap the arranged primary bags and seal them out automatically. Generally, there shall be a manual at the end of the line to take the baler bag onto the pallet directly.