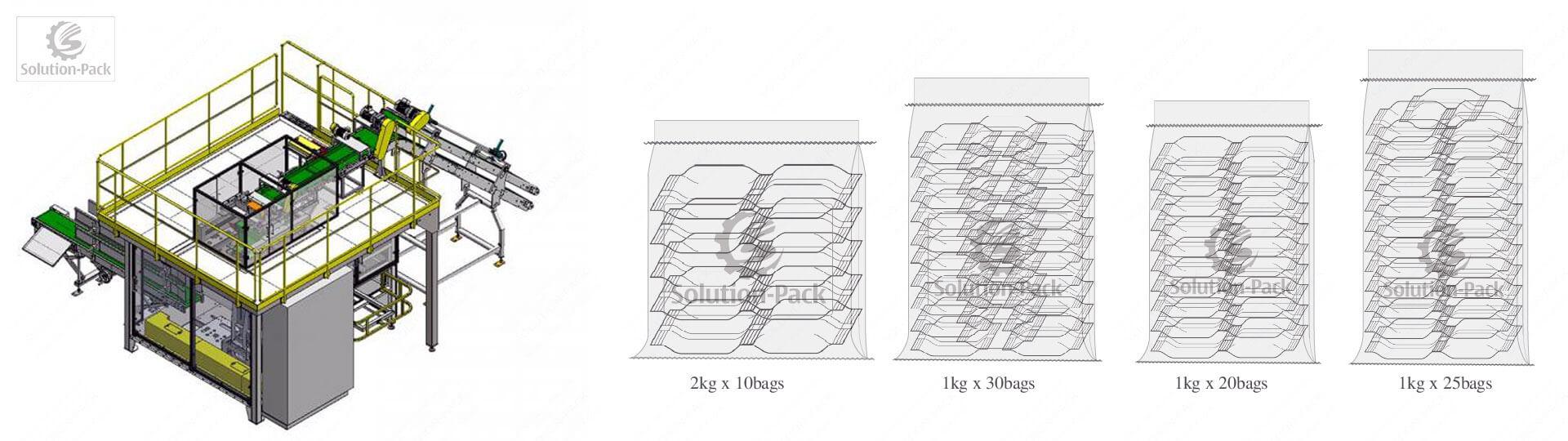

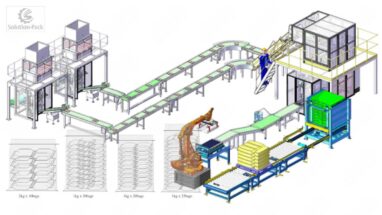

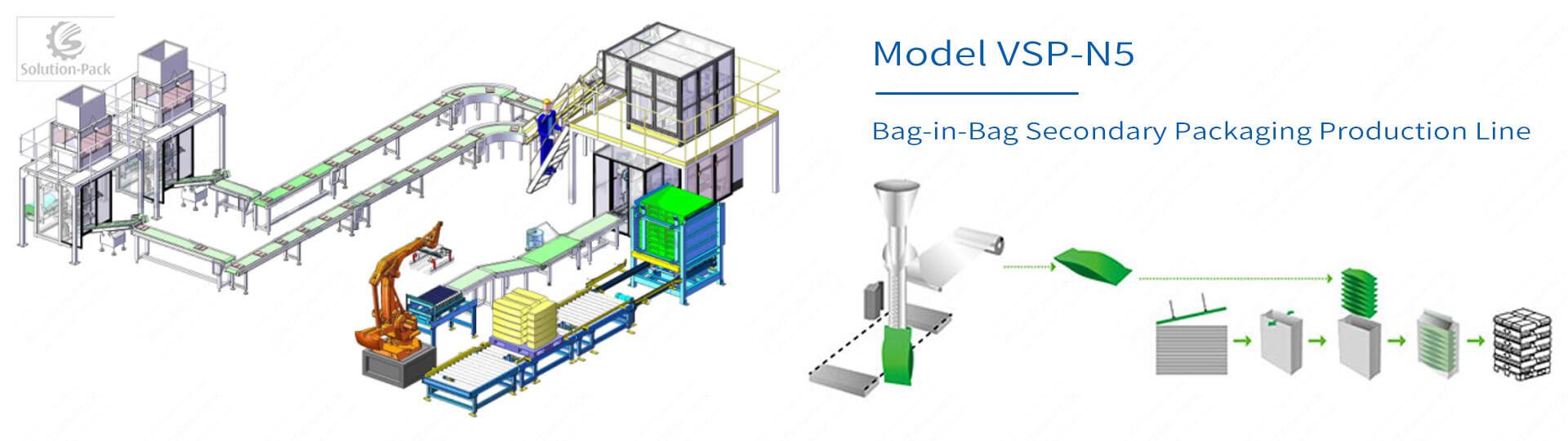

VSP-N5 model secondary packaging machine solution is an integrated bag-in-bag secondary repacking machine production line to bag the primary bags into the PP woven sacks and seal them automatically. The whole production line is generally composed of vertical packaging machines, primary bags conveying and arranging lines, secondary packing machines, and robot palletizing systems. The exact solution line shall be customized according to each user’s specific requirements and repacking patterns. This solution is widely adopted in corn seeds, paddy seeds, detergent powder, refined salt, refined sugar, and other related chemical markets.

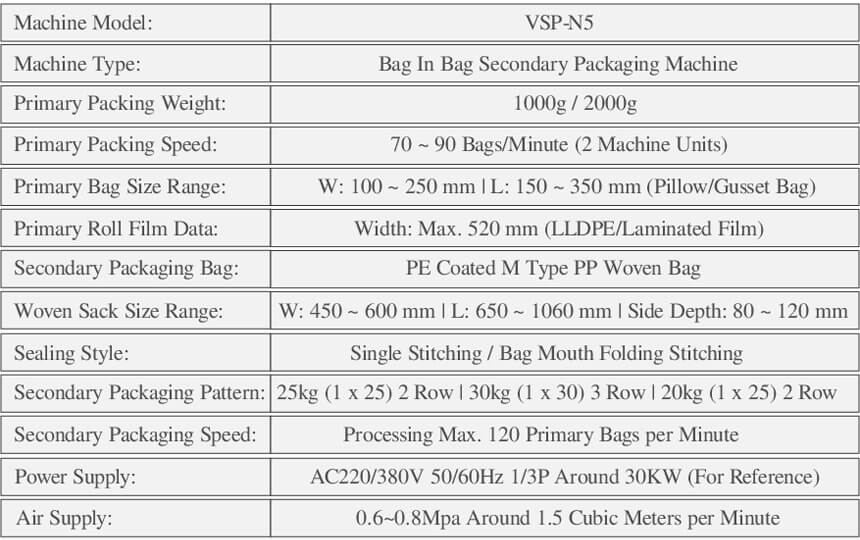

Secondary Packaging Machine Technical Data Sheet

Features of Secondary Packing Machine

This primary and secondary packaging machinery line is one of the most typical secondary packaging solutions in the market. The primary bags are generally produced by 2 or 3 sets of vertical packaging machines which could reach a total capacity of around 100 ~ 120 primary bags per minute. The conveying and bag arranging system shall deliver the bags to the position and drop them into the transitional hopper in order. The secondary packaging system shall feed the PP woven sack in position and offer a signal to the PLC system to release the transitional hopper to the sack directly. The manual only needs to prepare the empty woven sacks into the bag magazine for continuous production.

As a leading automatic secondary packaging machine manufacturer, Solution-Pack focuses on high-standard configuration to ensure the best machine running performance. All the control PLCs and HMI interfaces on this production line adopt the Germany Siemens Brand. The other electrical and pneumatic parts also use internationally famous brands like SMC Cylinder, Schneider Relay, Omron Temperature Control, New Long Sewing Machine, Markem Image Thermal Printer, etc. We firmly believe that stable performance is the core part of secondary packaging equipment.