Linden tea is a type of herbal tea made from leaves, flowers, and bark of the linden trees which are native to Europe. When consumed as a medicine in the form of tea, it has been shown to be high in many antioxidants, volatile oils, and other healing compounds. Coming from the tilia species of trees, linden tea has been used in Europe for many centuries to treat conditions such as anxiety, pain, coughs, and high blood pressure. To ensure the tea is easy to brew, some of the linden tea is packed in pyramid tea bags to sell to the market and some of the linden tea is ground into powder to pack into filter paper teabags. In this essay, we shall introduce six typical packaging solutions for linden tea bags.

Key Features of Linden Tea Pyramid Teabag Packaging Solution

The ATB-PD40 machine model is the standard integrated pyramid tea bag packing machine solution for producing foil-wrapped pyramid teabags. The whole machine unit adopts an integrated design style with both the inner bag system and the outer sachet system on one machine unit to save installation space. The machine unit adopts Fuji PLC control and Fuji Touch Screen operation. The Chinese and English double language operation interface is preset in the system for the user to switch easily. The standard machine unit could perform a stable running speed of 30 ~ 35 sachets per minute with a compact installation space requirement.

The ATB-PD50 machine model is a typical single inner tea bag packing machine solution. It could support producing both rectangular-type tea bags and triangular-type tea bags. There is a switch button on the HMI where the user could switch the tea bag shape freely according to the production needs. The 6-tunnel quantitative high-speed dosing system is applied to this machine unit to realize fast dosing and packaging. This machine unit could perform a stable running speed of 50 ~ 60 tea bags per minute according to the material features. It is very suitable for start-up factories that have limited budgets and installation space.

The ATB-PD50X pyramid teabag packing machine is a premium machine model that adopts the advanced horizontal out sachet forming system. Most of the electrical and pneumatic parts adopt Fuji and SMC technology to ensure the best running performance. The horizontal outer sachet system allows the machine to produce more compact outer sachet sizes with a “U” type easy tear notch to ensure a better product appearance. The machine unit also adopts an integrated design style with both inner and outer bag systems in a whole machine unit, but it could realize the speed of 45 ~ 50 sachets per minute. This teabag packing machine is suitable for big factories with large production capacity requirements.

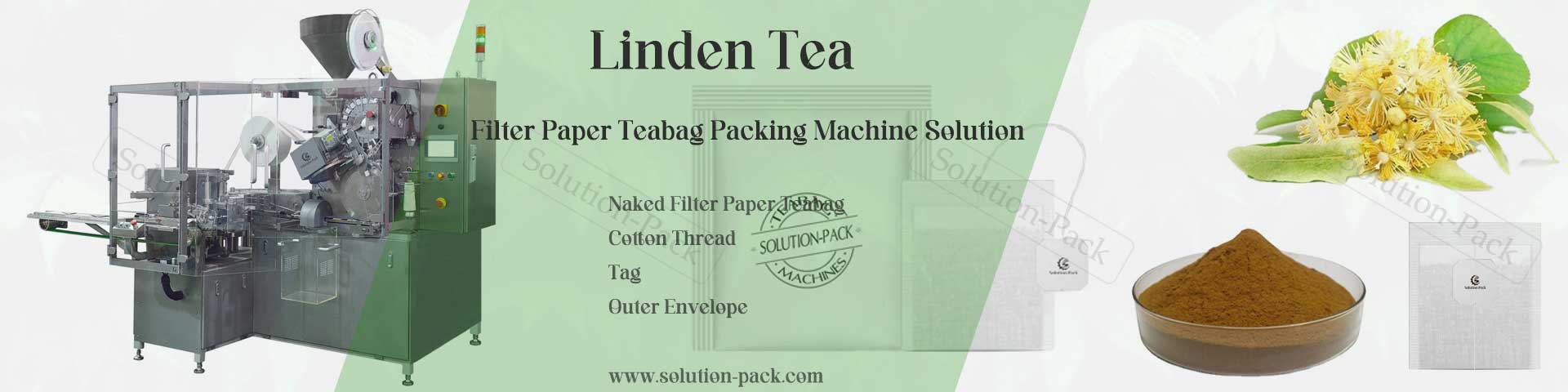

Key Features of Linden Tea Filter Teabag Packaging Solution

The ATB-S1 machine model is the most basic type of teabag packaging solution for linden tea powder products. This machine unit adopts Delta PLC control with a 7 inches Delta HMI for easy operation. The cotton thread system, heat seal ta system, and outer foil sachet system are all equipped on the machine unit to realize multi-functional production. No matter if you need to produce naked filter paper teabags or teabags with thread & labels, or foil-wrapped teabags, this machine unit could realize the function easily. Meanwhile, it could perform a stable running speed of 30 ~ 35 sachets/minute when turning all the functions on.

The ATB-S150 machine model is a premium machine model for producing filter paper teabags with thread and tags at a high speed of 150 teabags per minute. The whole machine frame adopts a fully mechanical design style, and automatic empty teabags detecting system, shortage of packaging materials detecting system as well as alarm system are all applied to this machine model to realize an advanced production process. The tea bag packing machine adopts Panasonic PLC control with Samkoon Touch Screen for operation. Meanwhile, the automatic counting and semi-automatic boxing system ensure that one operator could handle the production process easily.

The ATB-C6 machine model is a high-speed model for packing foil-wrapped filter paper teabags. It could perform a stable production speed of 105 sachets per minute with full sets detecting, rejecting, safety door and alarm system. According to the market requirements, the machine unit has designed an automatic counting system with PLC control. The user could pre-set the counting numbers and manually grasp into the box. We also support the design of two sets of ATB-C6 machines combined with one automatic boxing machine line if the user needs to realize a fully automatic production process.

To Get A Quotation

When you need to get a quotation for the Linden tea packing machine, please make market research first and then offer the below details.

1.) Do you need to pack linden tea leaves & flowers or linden tea powder?

2.) How much weight do you need to pack per tea bag?

3.) Do you need the outer envelope sachet function?

4.) How many bags do you need to produce per minute?

5.) Have you already sourced the packaging films? Or if you need us to count the quantity and supply with the machine together?

6.) What’s your official company name, address, and contact number?

You are warmly welcome to send the above details to our official mailbox: simon@solution-pack.com and we shall offer prompt feedback within 24 hours.