3-SIDE SEAL SACHET PACKING MACHINE SOLUTION INTRODUCTION

The multi-lane 3-side seal sachet packing machine solution is the sachet packaging machine that produces the 3-side seal sachets at high speed. It could be designed with 4 ~ 10 lanes according to the sachet size and target production capacity. When packaging different kinds of materials, it shall connect with different types of dosing filling systems and elevating systems. Briefly, we classify them into three groups: powder sachet packaging machine, liquid sachet packaging machine, and granule sachet packaging machine. The below link could guide you to the detailed introduction page to check all the information.

KEY ADVANTAGES OF THE HIGH-SPEED 3-SIDE SACHET PACKING MACHINE SOLUTION

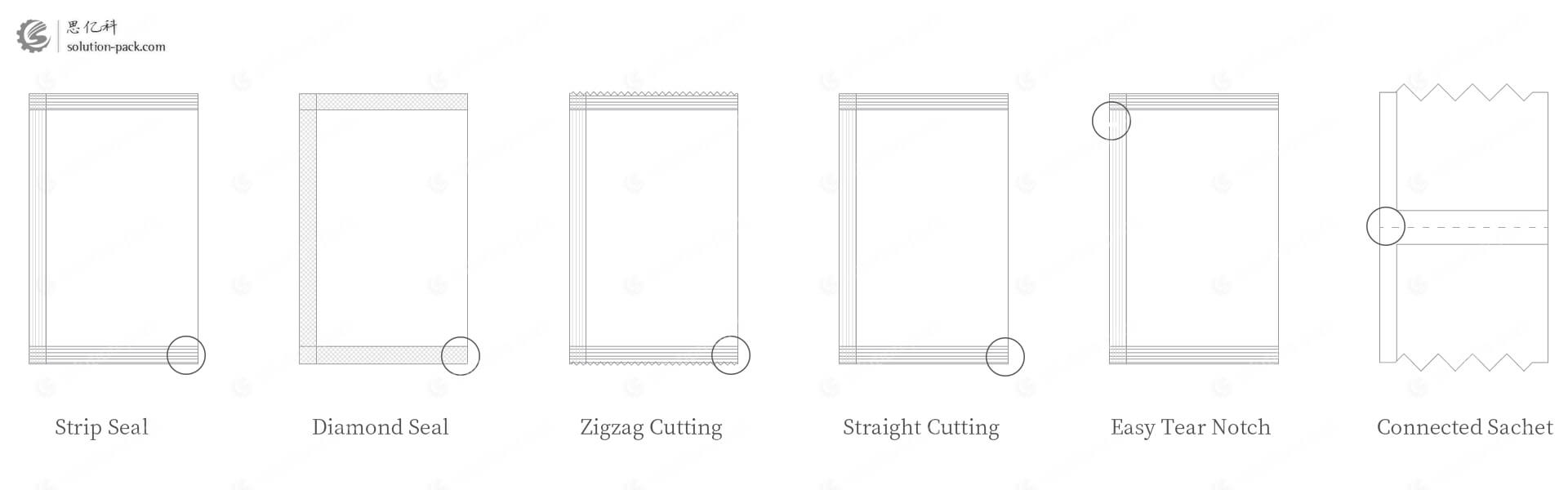

This high-speed sachet filling and sealing machine is applicable for dosing products and sealing in the form of the 3-side sealed sachet, including the sachet forming, product dosing, filling, and sachet sealing processes, with single cutting or string sachet cutting. The sachet packaging equipment shall pull laminate packaging film to the film-splitting devices, and the film split into specific lanes, then go through the sealing mold to seal the longitudinal side and first horizontal side. Meanwhile, the dosing device doses the product into the sachet through the open side and then does the last side sealing and cutting off.

This sachet packaging machine solution adopts a high-standard configuration to meet the international market. The PLC control and the HMI display system all adopt the German Siemens Brand. The digital temperature control uses the Japan Omron brand and the gear adopts the Germany IBC brand with a longer shelf time. The standard operation interface shall use CH / EN double language and customized language interface could be customized. The whole machine frame and the material contacting parts all adopt the food-level stainless steel to meet the international market needs.

Solution-Pack also provides customized production line service for the users. The automatic sachets arranging, counting, conveying, and boxing system could be connected to realize the whole production line process. This is suitable for factories that require large production capacities and is mostly used in the medicine production market. We customize the production line design according to the factory layout of the users to make the most efficient use of the space.

Generally, the whole sachet packing machine production line is composed of the following parts: (1), Elevator System; (2), Multi-Lane 3-side Seal Sachet Packaging Machine; (3), Sachet Counting and arranging System; (4.) Sachet Grouging and Conveying System; (5), Automatic Boxing Packaging System; (6), Automatic Boxing Arranging and Cartoning System Optional; (7), Automatic Box Arranging and Bopp Film Wrapping System. There are also some other optional functions like the instruction paper feeding system, the inkjet printer system, the laser printer system, etc. That is, the whole line shall be totally customized to the user’s needs and requirements. Welcome to visit our YouTube page to check the machine running details!

SUBMIT HERE TO REQUEST AN OFFICIAL QUOTATION

BENEFITS OF OUR SACHET PACKING MACHINE SOLUTIONS

● Providing professional project analysis services to propose the most suitable and economic packaging solutions to simplify the planning process for the user;

● Offering sample material testing services for the users on the standard packaging machine units;

● The solution layout design work shall follow the users’ factory layout and project-specific requirements to ensure all components meet their space and needs with great efficiency and reliability;

● Adopting centralized management for all devices to ensure the simplification of the management process as you can handle everything with one partner;

● All the electrical and pneumatic parts adopt internationally famous brands or equal brands to facilitate the user sourcing easy tear spare parts from the local market easily.