Introduction | Multi-Lane Sachet Machine

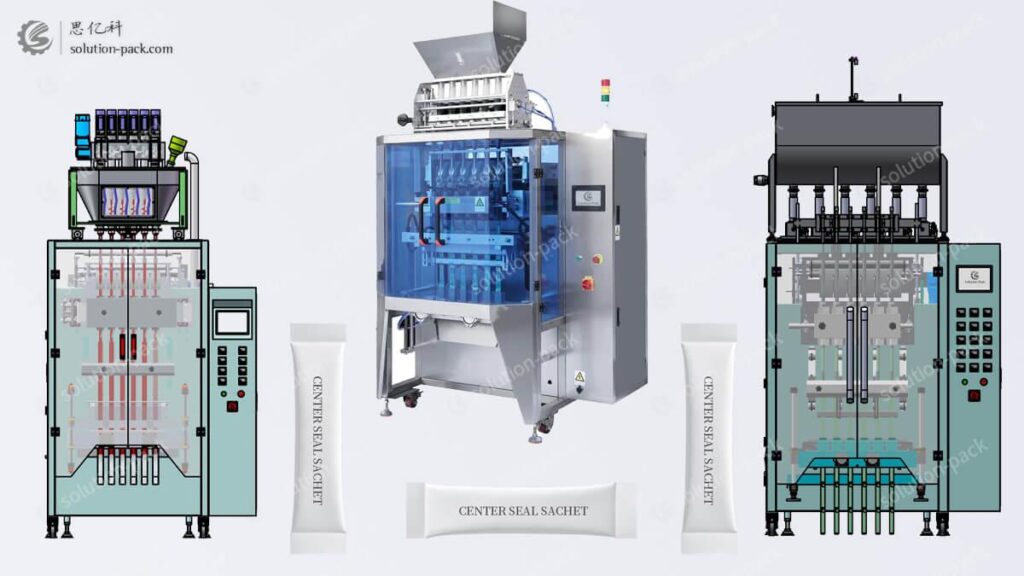

The multilane sachet machine solution from Solution-Pack could effectively support the users to package the liquid, powder, and granule products into sticks or sachets automatically. These sachet packing machines could generally produce around 100 ~ 350 sachets per minute according to the material features and production requirements. They are widely applied in food, chemical, medical, daily care, and drinks markets to improve production efficiency and save labor costs for the users. Each machine unit shall be totally customized so as to meet the users’ needs well. According to the sachet size difference, we could classify them into three groups: center-seal sachet packing machine, 3-side seal sachet packing machine, and 4-side seal sachet packing machine.

Key Advantages of The Multi-Lane High-Speed Sachet Packing Machine

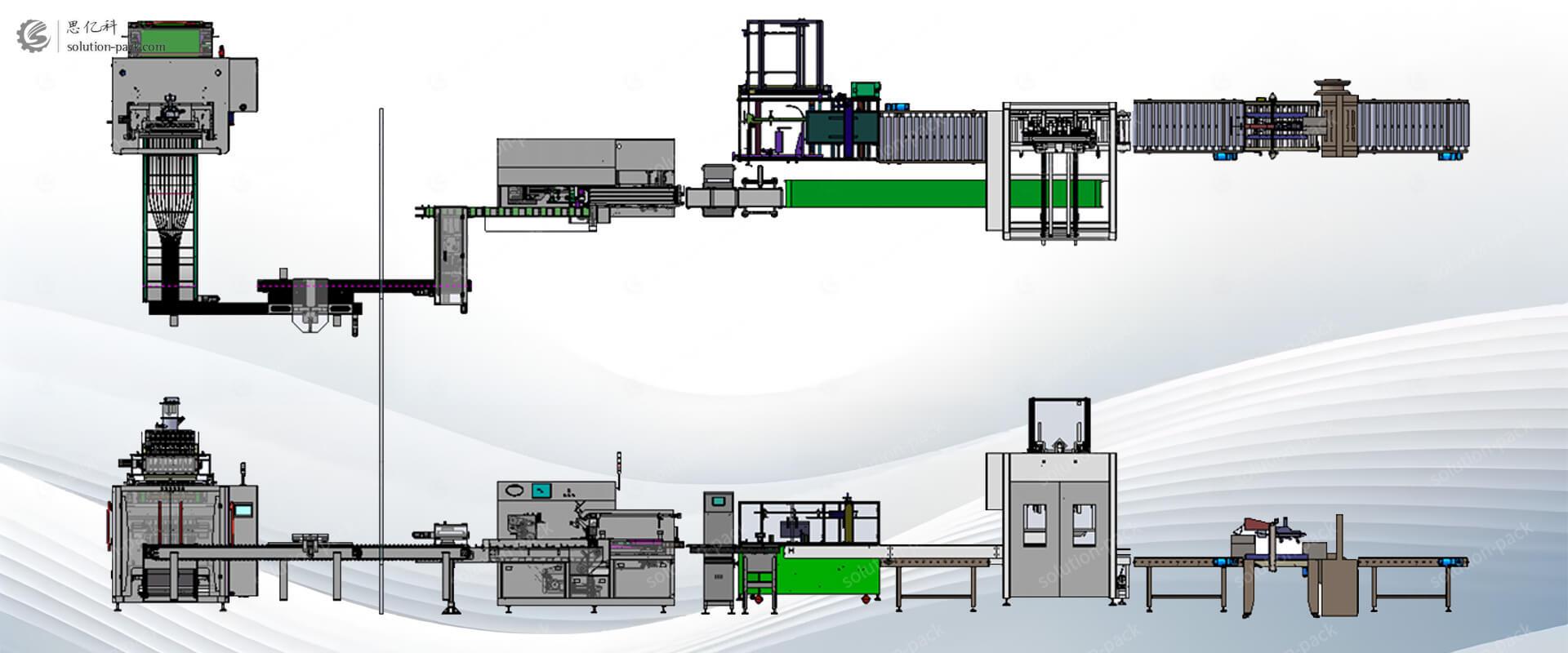

Each type of packaging machine solution adopts a unique design with different kinds of dosing filling systems to realize the function of automatic material dosing, film pulling, date printing, film splitting, sachet forming, material filling, heat-sealing, and finished sachets output. The standard machine unit could connect with the automatic sachet arranging grouping system and the automatic boxing system to realize the whole production line process. There are also other optional functions like laser printers, vacuum elevators, metal detectors, check weighers, and inkjet printers for the users to choose from directly.

According to the packaging material difference, these packaging machines could also be classified into three groups: powder sachet packing machine, liquid sachet packing machine, and granule sachet packing machine. The powder sachet packaging machine shall connect with the servo-controlled auger dosing filling machine. The liquid sachet packing machine shall connect with the piston-type filling pump, and the granule sachet packing machine shall connect with the high-speed volumetric cup filler. Meanwhile, according to the features of the packaging materials, the elevating system shall also differ.

These packaging machine solutions adopt a high-standard configuration to meet the international market. The PLC control and the HMI display system all adopt the German Siemens Brand. The digital temperature control uses the Japan Omron brand and the gear adopts the Germany IBC brand with a longer shelf time. The standard operation interface shall use CH / EN double language and customized language interface could be customized. The whole machine frame and the material contacting parts all adopt the food-level stainless steel to meet the international market needs.

Multi-Lane Powder Sachet Packaging Machine

Multi-Lane Granule Sachet Packaging Machine

Multi-Lane Liquid Sachet Packaging Machine

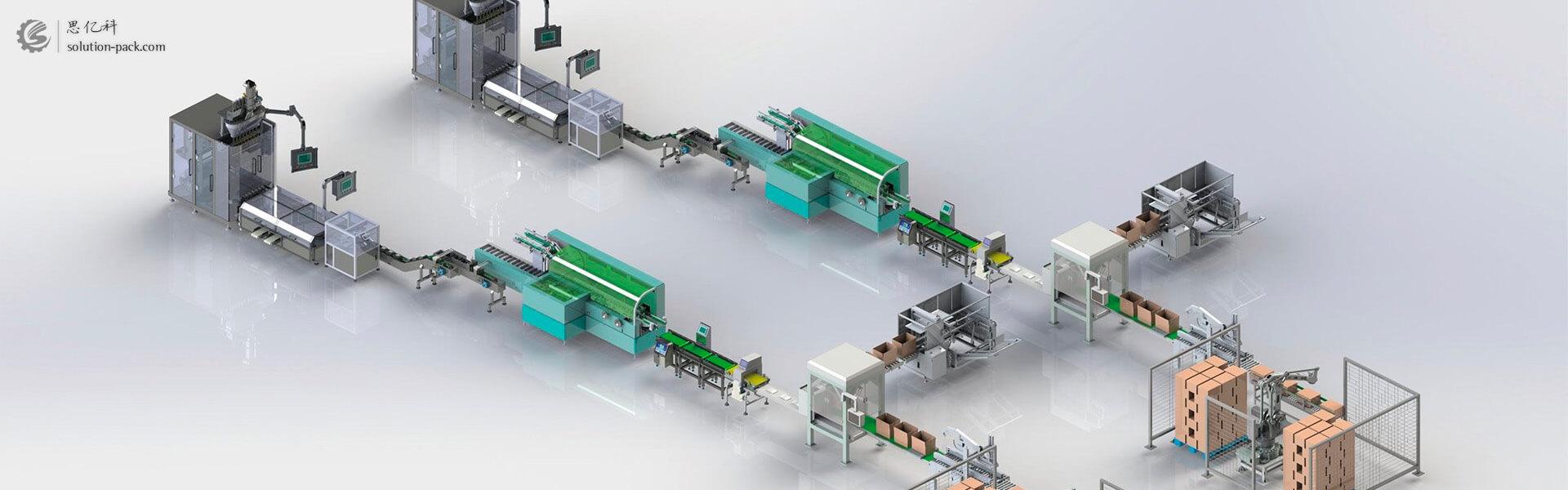

Reference Multilane Sachet Machine Production Line Design

Generally, the whole sachet packing machine production line is composed of the following parts: (1), Elevator System; (2), Multi-Lane Sachet Packaging Machine; (3), Sachet Counting and arranging System; (4.) Sachet Grouging and Conveying System; (5), Automatic Boxing Packaging System; (6), Automatic Boxing Arranging and Cartoning System Optional; (7), Automatic Box Arranging and Bopp Film Wrapping System. There are also some other optional functions like the instruction paper feeding system, the inkjet printer system, the laser printer system, etc. That is, the whole line shall be totally customized to the user’s needs and requirements. Welcome to visit our YouTube page to check the machine running details!

BENEFITS OF OUR SACHET PACKAGING MACHINE SOLUTIONS

● Providing professional project analysis services to propose the most suitable and economic packaging solutions to simplify the planning process for the user;

● Offering sample material testing services for the users on the standard packaging machine units;

● The solution layout design work shall follow the users’ factory layout and project-specific requirements to ensure all components meet their space and needs with great efficiency and reliability;

● Adopting centralized management for all devices to ensure the simplification of the management process as you can handle everything with one partner;

● All the electrical and pneumatic parts adopt internationally famous brands or equal brands to facilitate the user sourcing easy tear spare parts from the local market easily.