CENTER-SEAL SACHET PACKING MACHINE SOLUTION INTRODUCTION

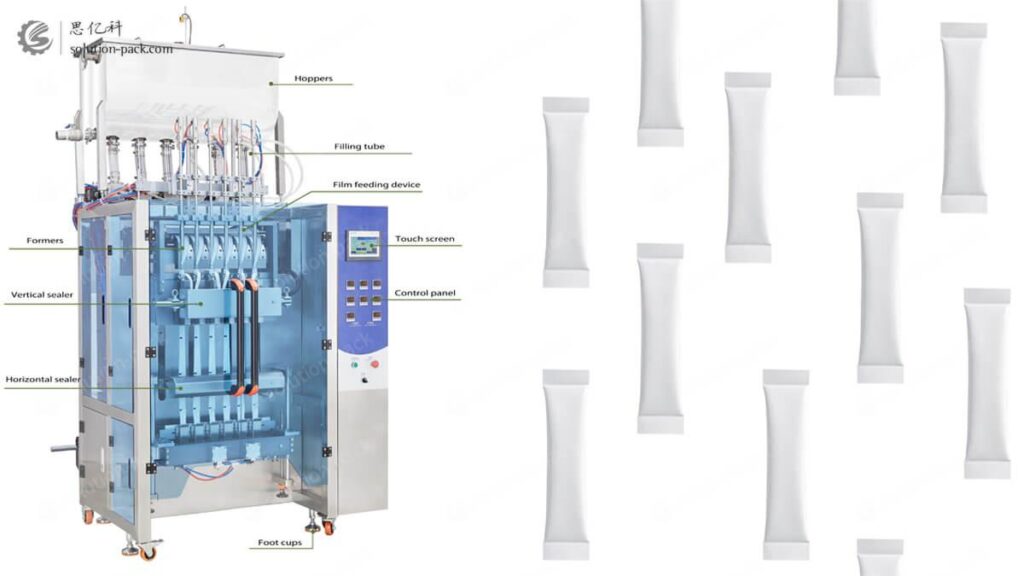

The multi-lane center-seal sachet packing machine solution is the sachet packaging machine that produces the back seal stick and sachet at high speed. It could be designed with 4 ~ 10 lanes according to the sachet size and target production capacity. When packaging different kinds of materials, it shall connect with different types of dosing filling systems and elevating systems. Briefly, we classify them into three groups: powder sachet packaging machine, liquid sachet packaging machine, and granule sachet packaging machine. The below link could guide you to the detailed introduction page to check all the information.

KEY ADVANTAGES OF THE HIGH-SPEED SACHET PACKING MACHINE SOLUTION

The center-seal sachet packing machine solution could connect with different types of dosing systems to pack various products. The whole machine frame and the material contacting parts are made of SS304 stainless steel which meets food sanitary production needs well. The machine stands are equipped the universal wheels for easy movement adjustment. The wires and air tubes are arranged and grouped well for easy maintenance and better appearance. The transparent Lexon board safety door system allows the user to check the mechanical movement inside the machine clearly.

Solution-Pack only provides high-standard configuration machine units for the users. The touch screen and PLC control use the Germany Siemens brand, the temperature control and the relay use the Japan Omron brand, and the gear adopts the Germany IBC brand with a longer shelf time. The standard HMI interface shall input the CH / EN double language interface and customized operation language could be customized. There are different types of elevator systems for the user to choose from to realize the automatic elevating process.

Unlike the used sachet packing machine for sale in the market, our center-seal sachet packing machine is fully customized to the user’s sachet size and required production capacity. Generally, each lane could produce 25 ~ 35 cuts per minute according to the powder features and filling weight. The film pulling and splitting system shall be designed according to how many lanes the users require. We could manufacture max. 10-lane sachet packing machine which could perform a high production capacity of around 250 ~ 350 sachets per minute.

FAQ ABOUT MULTI-LANE SACHET PACKAGING MACHINE SOLUTIONS

What’s the cost of the multi-lane sachet packing machine?

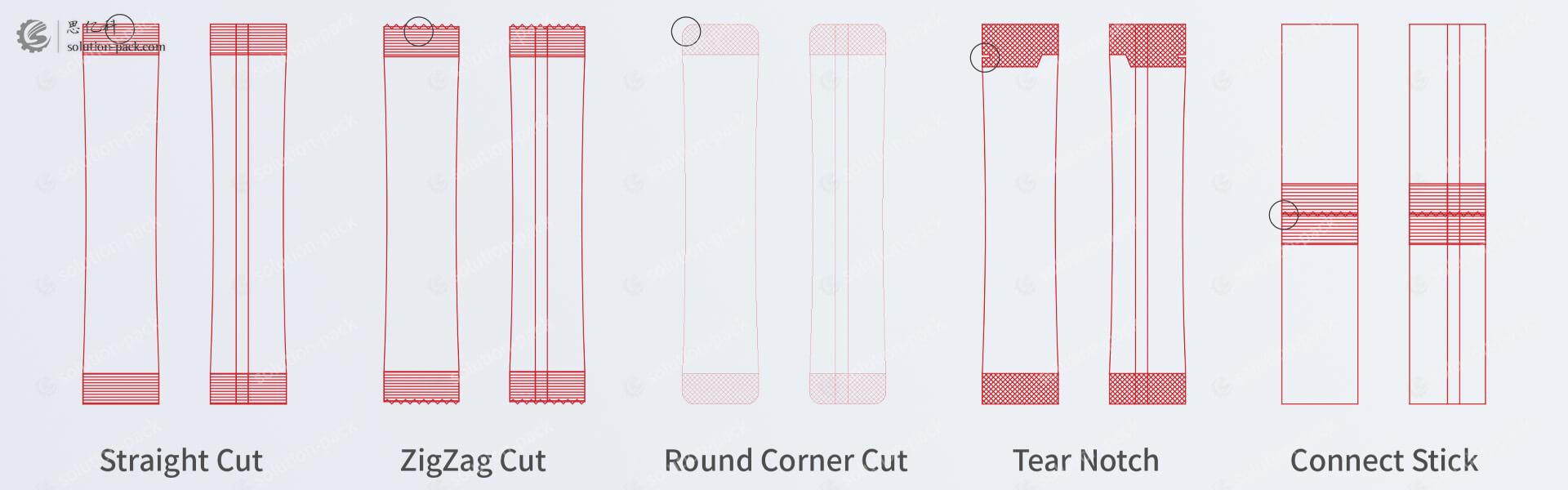

The multi-lane sachet filling and sealing machine is not a standard machine unit. We shall propose how many lanes the users should adopt according to their target production capacity. Meanwhile, there are different kinds of optional functions like round corner cut, chain sachet, counting grouping system, etc. which the users could choose from. Thus, send an email to Solution-Pack with your detailed requirements, and we shall analyze and propose the most applicable system for your project.

How many sachets could the automatic sachet-packing machine produce per minute?

The automatic sachet packing machine speed is decided by three characters: 1, the packaging product features; 2, the target packing weight; and 3, the lane quantities that the machine is designed. It could range from a minimum of 100 sachets per minute to a maximum of 350 sachets per minute. Thus, there must be one machine model that meets your production needs well.

SUBMIT HERE TO REQUEST AN OFFICIAL QUOTATION

BENEFITS OF OUR SACHET PACKING MACHINE SOLUTIONS

● Providing professional project analysis services to propose the most suitable and economic packaging solutions to simplify the planning process for the user;

● Offering sample material testing services for the users on the standard packaging machine units;

● The solution layout design work shall follow the users’ factory layout and project-specific requirements to ensure all components meet their space and needs with great efficiency and reliability;

● Adopting centralized management for all devices to ensure the simplification of the management process as you can handle everything with one partner;

● All the electrical and pneumatic parts adopt internationally famous brands or equal brands to facilitate the user sourcing easy tear spare parts from the local market easily.