Multi-Lane Powder Sachet Packing Machine Introduction

The model ML-F3 automatic powder sachet packing machine unit is designed for non-free flow powder products into the 3-side seal sachets automatically. The whole machine unit adopts an advanced design and can connect with the screw-type elevator or vacuum elevator to realize the material elevating process. The standard machine unit shall realize the function of powder dosing, film pulling, date printing, film splitting, material filling, heat-sealing, and finished product output. There are also other optional customized functions for the users to choose from. This powder sachet packaging machine solution is widely applied in non-free flow powder markets like milk powder, soybean powder, protein powder, energy drinks, nutritional products, etc.

Typical Features of The Powder Sachet Packing Machine Solution

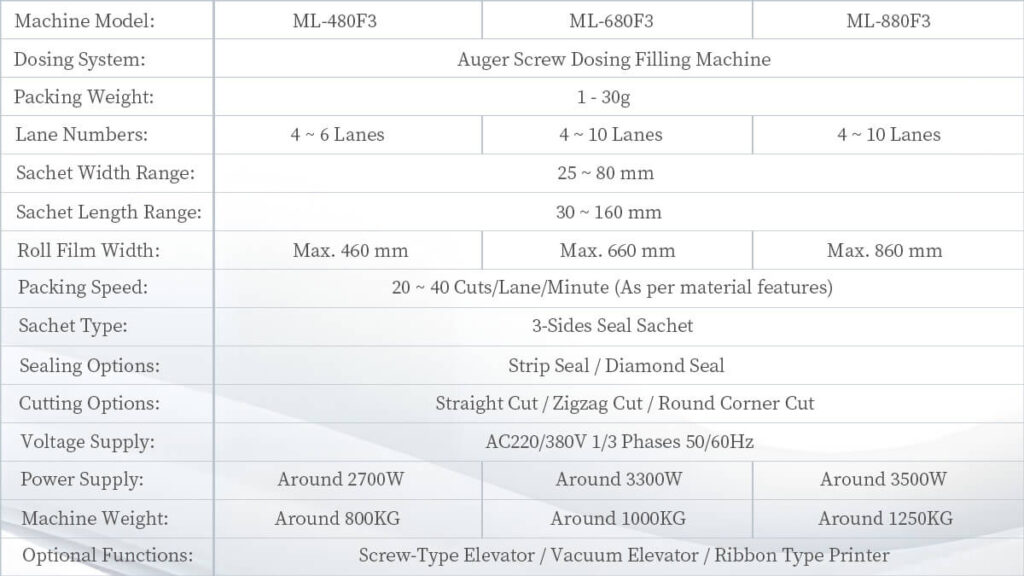

This powder sachet filling and sealing machine unit adopts the multi-lane design style which could perform the packaging speed of around 20 ~ 40 cuts per lane per minute according to the material features and packaging weight. It could support the users to improve the production capacity effectively and save labor costs. The machine’s hopper could connect with the user’s front production line storing tank to realize continuous packaging and facilitate the cleaning process after production. The finished product output part could customize the counting and grouping device to support the users to repack the sachets into big bags or boxes. Welcome to check the machine running details on our YouTube Channel!

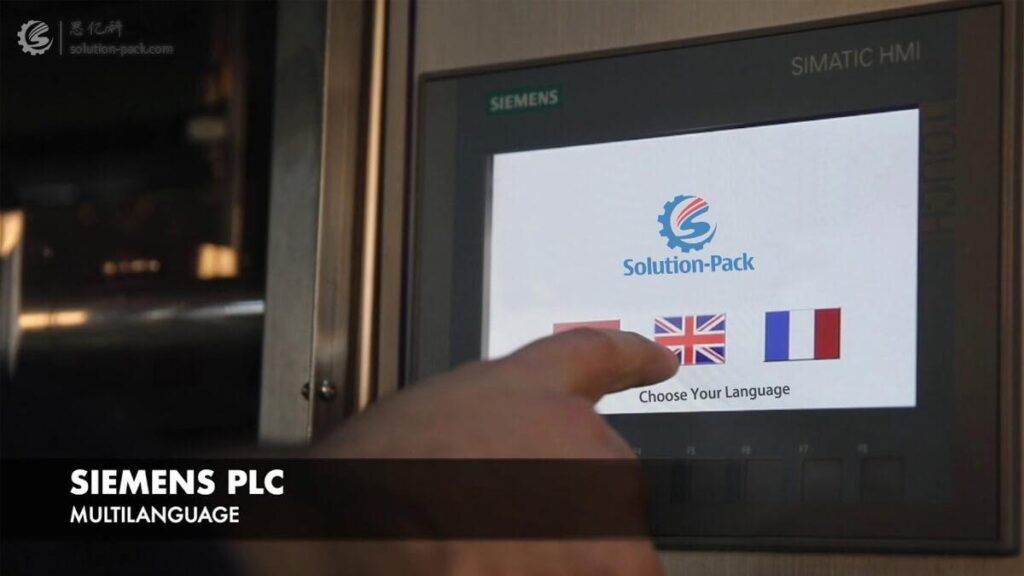

The 3-side seal sachet packing machine adopts a high-standard configuration to meet international market needs. Intelligent Germany Siemens PLC and HMI Interface are used for better operation experience. The other pneumatic and electrical parts also adopt internationally famous brands like SMC, IBC, OMRON, SCHNEIDER, AIRTAC, etc. It could ensure the stable performance of the machine and also facilitate the user to source spare parts from the local market easily. The whole machine frame and the material contacting parts use food-level stainless steel and the safety door adopts the Lexan board with high transparency for checking the mechanical movements.

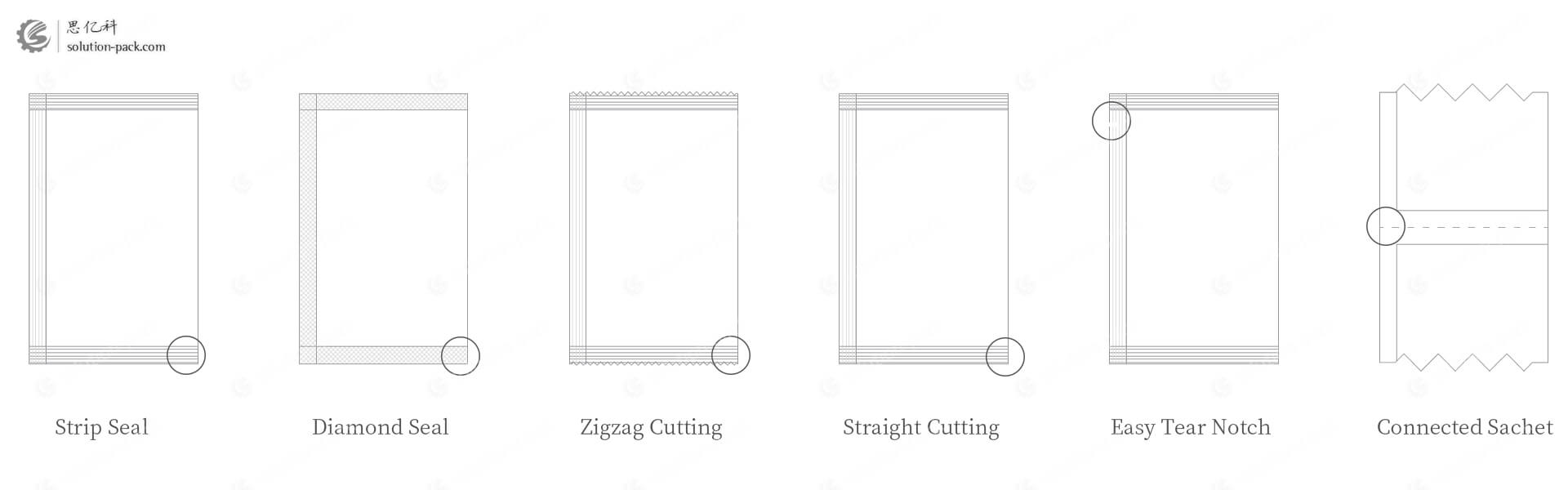

The servo motor-controlled auger dosing system is adopted for the powder weighing and filling process. It could ensure stable filling speed with high accuracy control which could save production waste for the factory. The unique film-splitting system could separate the film into independent lanes for sachet forming. The dust-collecting system could be connected to collect the powder dust which could provide a clean production environment. There are different kinds of sealing and cutting styles for the users to choose from and the the machine shall be customized to the requirements.

FAQ About The Powder Multi-Lane Sachet Packaging Machine

How does the multi-lane powder sachet packing machine work?

The powder sachet filling machine shall use the vacuum elevating system to elevate the powder products into the hopper of the machine. Then the stick packing machine shall pull the film, print the date, and then split the film into pre-set lanes. The sachet former system of each lane shall form the film into a 3-side seal sachet shape. Then the piston-type pump shall dose the liquid products and fill into the sachet of each lane. Finally, the machine shall seal the sachet and cut it into single sticks.

How many sachets could the high-speed sachet packaging machine produce per minute?

The 3-side seal sachet packing machine solution adopts the multi-lane design style. Unlike the used sachet packing machine for sale in the market. The production capacity is decided by how many lanes the user needs to customize. Each lane could produce 20 ~ 40 cuts per lane per minute according to the material features and packaging requirements. The machine could maximum customize 10 lanes for production. You could send an email to us and we shall analyze in detail for your sachet packing machine project.