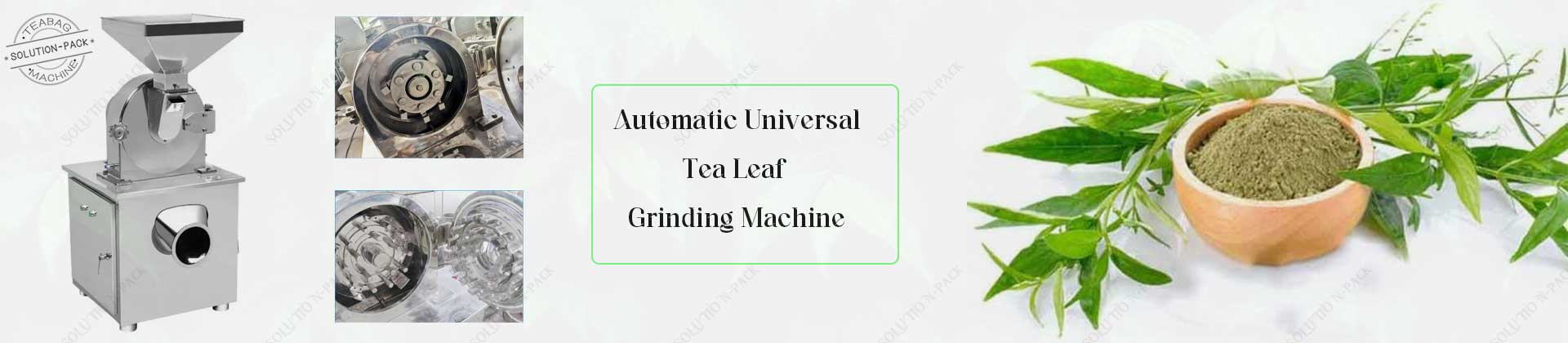

The tea leaf automatic universal grinding machine used the high-speed relative motion between movable gears to crush the leaf materials through the impact between gears, friction, and impact between materials. The utility model has the advantage of simple structure, firmness, stable operation, and good crushing effect. The crushed material can be directly removed from the grinding chamber of the main engine, and the particle size can be obtained by changing the screen with different apertures. This universal grinding machine unit is widely applied in the crushed tea leaf, herbal tea, and flower tea market to grind the material into 20 ~ 60 meshes size to meet the requirements of the filter teabag packing machine.

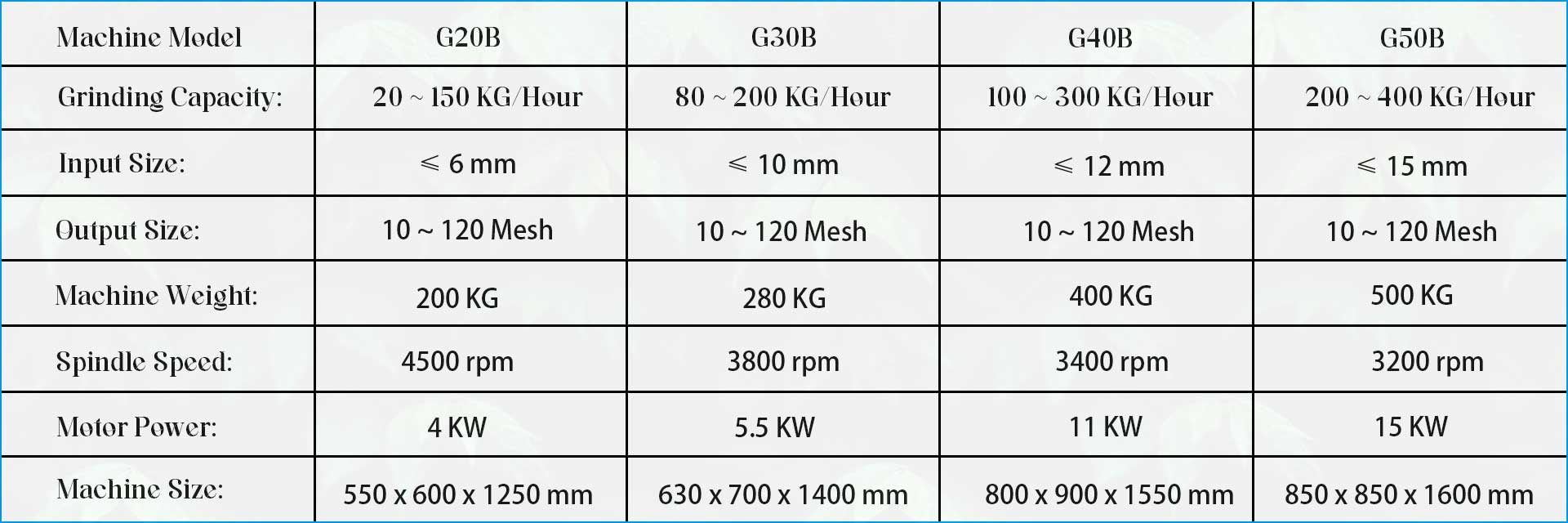

Technical Data

Typical Features of Universal Grinding Machine Solution

Cutterhead high-speed rotation shear grinding. There is a screen outside the cutter head for filtration. After crushing, the powder passes through the screen and enters the discharge port. This powder grinding machine is widely applied in industries, such as medicine, chemical, food, etc., for grinding dry and fragile materials. Materials with low softening points and big viscosity are not appropriate for this machine. The main motor shall adopt the well-known brands high power all copper motor which reaches protective class IP55. The electrical components adopt Schneider Electric to ensure the best performance. And the key part of the machine adopts NSK sealed bearing with durable anti-corrosion cracking.

The water cooling system can effectively reduce the temperature of the bearing and the cavity, avoid high-temperature damage to the material, and also protect the bearing to ensure stable and lasting operation. The door is equipped with a proximity switch which could realize the instant stop when the door is opened, and effectively ensure production safety. The layout of the control area is reasonable. There is a meter that can tell the operator the feeding speed whether too fast or too slow. The metal surface has been professionally polished to make it smooth and beautiful.

Advanced Advantages of The Universal Grinding Machine Solution

This tea leaf grinding machine has equipped special safety switch on the door. The machine shall stop immediately when the door is opened. And the emergency stop is also installed around the equipment’s operation area to ensure the operation safety. Meanwhile, there is an internal circuit breaker to protect the instrument from overload. All the machine frames and the material contacting parts are strictly made of food-grade materials to meet the GMP and CE standards.

This herbal grinding machine has strong powder and a good crushing effect. The processing is completed once and will not resume work with a scientific design which ensures stable operation for a long time. Solution-Pack strictly controls the quality of the spare parts and materials. The wall of the grinding machine champer is bigger, thicker, anti-tearing & torsion, and not easy to deform.

To Get The Official Quotation

1. What kind of products do you need to grind?

2. How many meshes do you need to grind into?

3. How much weight do you need to grind per hour?

4. What’s the available voltage, phase, and frequency in your factory?

5. Do you need any other teabag packing machines for production?

6. When do you need to install the machine unit or just need a brief budget?

7. Please provide your official company name, address, and contact number.

Solution-Pack shall work the best to support your project after you send the above details to our official mailbox: simon@solution-pack.com or submit the inquiry form.