ATB-PD50 automatic pyramid teabag packaging machine unit is a pure inner teabag packing machine model. It is connected to the 6-tunnel weighing filling system to pack the tea products into the naked triangular teabags or the naked rectangular teabags and output them automatically. Adopting the advanced ultrasonic sealing system, the machine unit could work for Nylon Netting Film, PLA Netting Film, PET Netting Film, and Non-Woven Fabric Film according to each client’s production needs. This machine model is widely applied to Green Tea, Black Tea, Moringa Tea, Pu’er Tea, Formula Tea, Babao Tea, Health Tea, Chinese Medicine Pieces, etc.

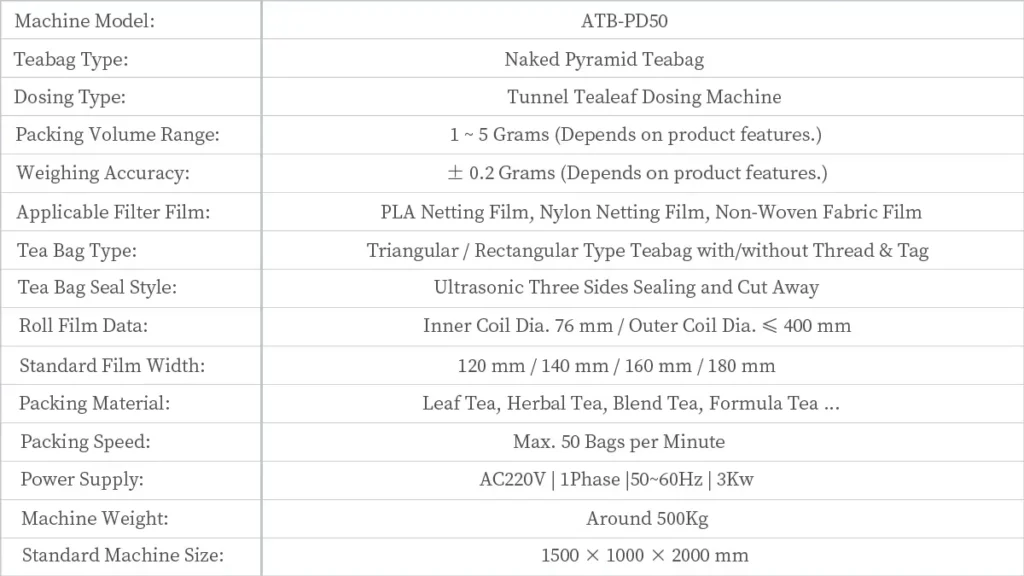

MODEL ATB-PD50 | TECHNICAL DATA

This pyramid teabag packing machine unit is a high-speed model for producing pure inner teabags with or without thread and tag. Except for producing triangular and rectangular teabag shapes, it could also be customized to produce pillow-type teabags to hold more tea products inside. It could also connect with an outer sachet packaging machine to realize the function of inserting the inner teabag into the foil sachet and output automatically. Most users choose this teabag machine to produce the inner bags and then repack them into zipper pouches or cans for better marketing or store them in the big bucket for direct resale.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE PYRAMID TEABAG PACKING MACHINE

- The naked pyramid teabag packaging machine unit adopts ultrasonic sealing and cutting, to produce beautiful pyramid netting bags or rectangular netting bags. The automatic quantitative 6-tunnel measurement can easily change the filling amount in the production. The machine unit could be applied to pack pre-mixed tea products or single tea products, and it could also be applied to pack formula tea products;

- The 6-tunnel design allows the machine unit to pack max. 3 kinds of recipe tea products. All the dosing weight data could be set on the HMI directly according to the production requirements. This pyramid tea bag packing machine unit could connect with a Z-Type Elevator system if the client packs pre-mixed tea or single tea products. The advanced design allows the pyramid tea bag packaging machine unit to perform the production capacity of 3000 Tea Bags per Hour which is the first choice of most start-up companies;

- Using Siemens PLC control, touch screen operation, and more stable performance, the operation is simple and more human-friendly. SMC pneumatic components, and Schneider electrical components, extend the service life of the pyramid tea bag packaging machine. The use of mechanical and electrical integration design to ensure replacement data without stopping/shutting down. One key switch is designed on the HMI for the client to easily change the inner bag shape from Triangular type to rectangular type.

- It is well-known that the pyramid teabag is a well-shaped tea bag with a good appearance and is more favorable to the market. Traditional tea bags adopt filter paper film which is soft and only applicable for granule or powder-type tea products. However, the pyramid teabag has a bigger volume and could support the clients to pack more tea leaves into it. Getting a suitable pyramid teabag packing machine for production becomes more and more important. Solution-Pack has focused on the teabag packing machine market for over 12 years with rich experience. We only propose the most suitable packaging solution to meet the client’s production needs;

- We supply sample material testing services for the client who is a start-up on the tea bag packaging machine project. Each client could deliver around 2KG sample tea materials to us. The products must be vacuum-packed before delivery. Then we shall arrange the machine to test the material and propose the most suitable inner and outer tea bag size for the client. In this way, it could better ensure the client gets the most accurate packaging data for their products. Solution-Pack could also supply the client with customized packaging materials like PLA/Nylon/ Non-Woven Fabric Netting Films.