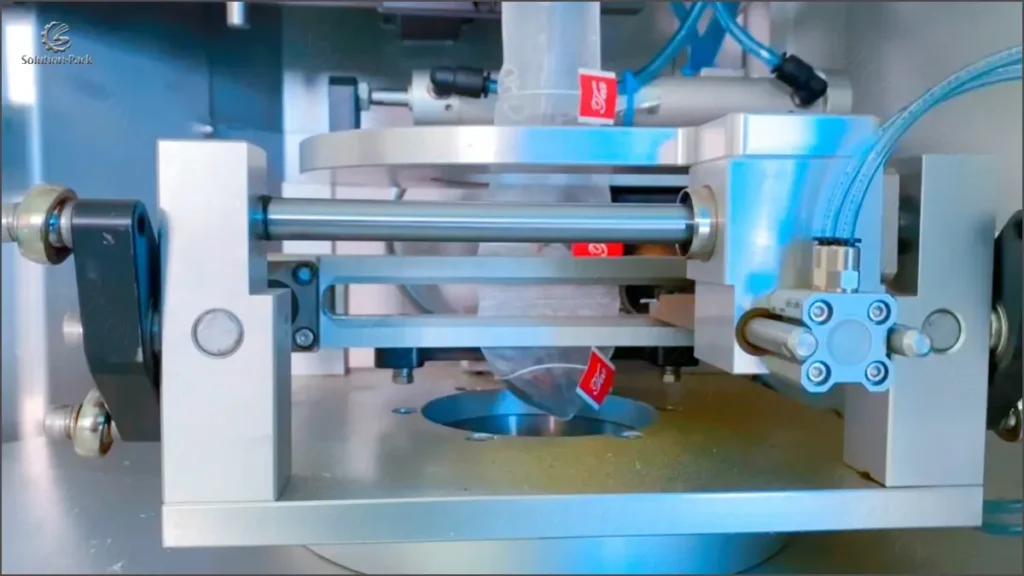

The pyramid teabags are normally made of nylon, PLA, or non-woven fabric mesh film with advanced ultrasonic sealing technology. Different from the filter paper teabags, this packaging pattern could be used to pack the original tea leaves, herbs, cut plants, mixed herbs, flowers, etc. It could also better keep the original taste of the tea products for the drinkers. We shall introduce 4 kinds of pyramid tea bag packing machine solutions that could support the users to realize the automatic production process easily. Each teabag packing machine system has unique features and produces certain fixed sachet sizes for the users.

PYRAMID TEABAG PACKAGING MACHINE SOLUTIONS

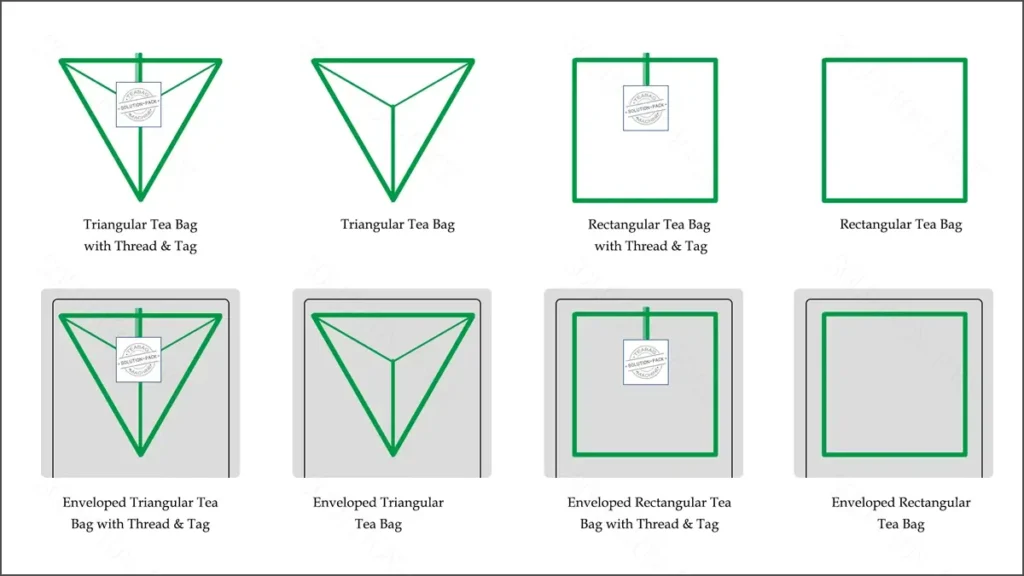

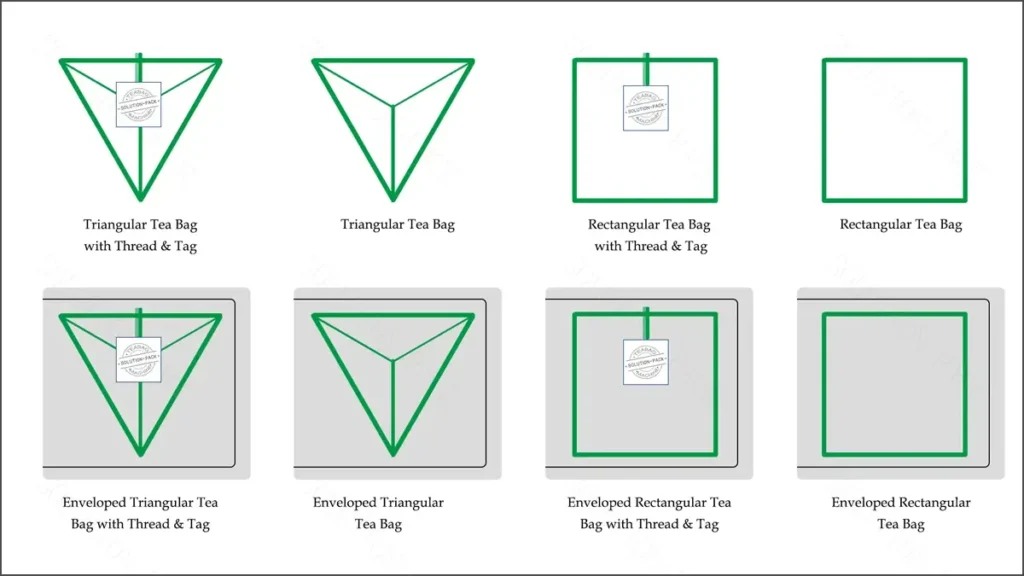

The pyramid tea bags are small and mostly sealed by ultrasonic sealer. This packaging pattern is difficult to produce manually with a high speed. Most tea factories worldwide use automatic teabag packaging machine equipment to produce pyramid tea bags with high production capacity. The equipment uses the quantitative tea leaves dosing filling system and ultrasonic sealing system to make triangular or rectangular teabags and insert them into the foil sachets. According to users’ outer sachet design style and required production capacities, there are different machine models for options.

SUBMIT HERE TO CONTACT US

ADVANCED FEATURES OF THE PYRAMID TEA BAG PACKING MACHINE

1.) Wide Application Range: The pyramid tea bag packing machine could connect with the linear tea leaf dosing filling machine, the multi-tunnel dosing filling machine, or the multi-head weighing filling machine to pack leaf or granule products with high weighing accuracy. These teabag packing machine solutions are widely used to pack original green tea leaves, black tea, single herbal teas, mixed herbal teas, flower teas, formula teas, healthy drinks, medical drinks, etc. It could also be applied to pack the granules or particles in the environment protection market;

2.) Customized Solution Design: Solution-Pack offers customized solution design for users to meet their factory layout perfectly. If the users’ warehouse height permits, we shall use the Z-Type elevator to deliver the material to the hopper of the weighing machine directly. However, if the height is limited, we shall provide the floor design style to install the weighing system on the floor directly and then elevate the weighed products to the packing machine. According to the user’s production needs, we could also design the weight checker and kick-off system as well as the sachets collecting system for the users.

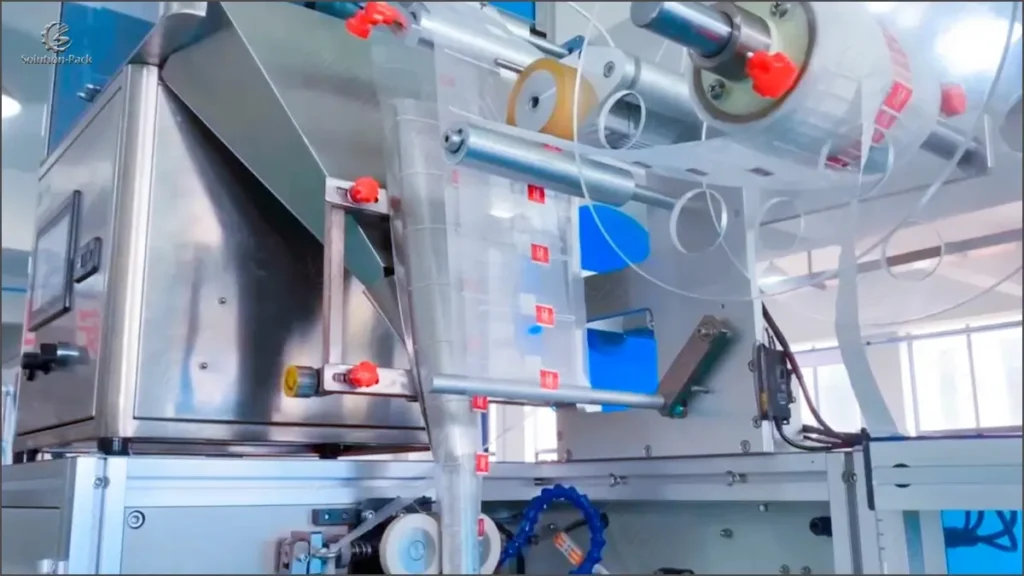

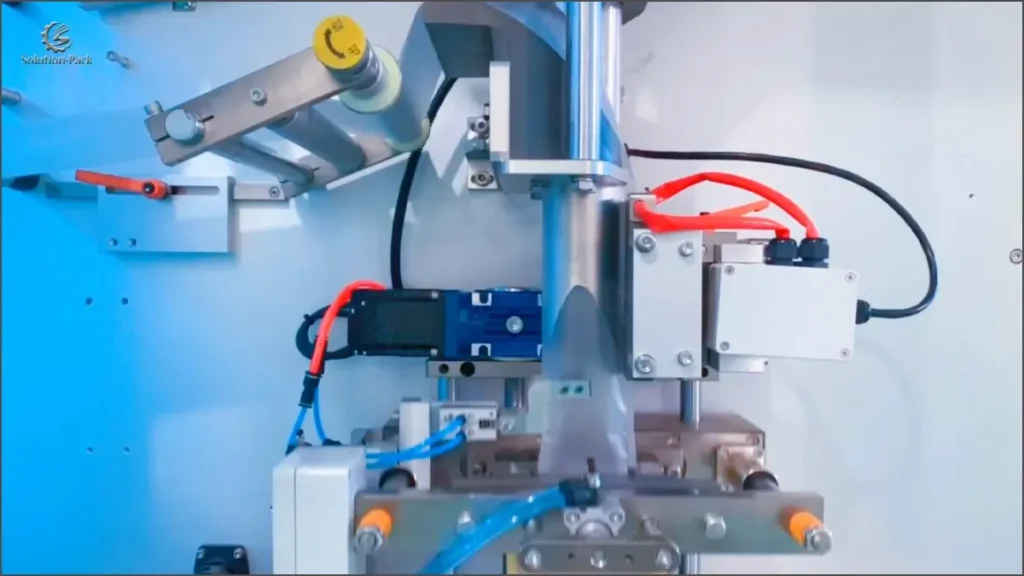

3.) High Standard Configuration: To better ensure the performance of the pyramid tea bag packing machine, we adopt the internationally famous brand electrical and mechanical parts for all the machine models. The intelligent Germany Siemens or Japan Fuiji PLC & HMI interface is applied to offer the best operating experience for the users. The operating language shall be standard CH/EN double language interface and customized language could be required. The machine frame shall use the strengthed coated carbon steel and the material contacting parts shall use the food level stainless steel to meet the food production needs.

These teabag machines could produce rectangular and triangular shape inner teabags with a simple button on the HMI to change the bag’s shapes directly. Meanwhile, these machine units could also produce pure inner teabags without outer envelope sachets by turning the inner sachet feeding tunnel to the outside of the machine. This design could better support users doing OEM production for the market or stocking the teabags for future markets. The users could also choose the function of nitrogen filling to extend the shelf-life of the products. All the machine models running performance can be checked on our YouTube channel.

CHOOSE SOLUTION-PACK | FIND THE BEST PYRAMID TEABAG PACKING MACHINE

Solution-Pack is a leading packing machine manufacturer and trader in China with over 12 years of experience. We have professional assembling workers, technical teams, and marketing departments. Our major markets include snack foods, daily care products, cosmetics, tea, coffee, grains, seeds, animal feeds, pet foods, and chemical fertilizers. We treat each project seriously and comprehensively study users’ detailed requirements before proposing suitable and applicable packaging solutions. We offer high-standard machine equipment with official CE certification from ECM and all the goods will be packed in non-fumigation export wooden cases. Welcome friends worldwide to contact and work together with us to build up their projects!

After-sale service is the priority in our work and users’ experience is the top mission of our enterprise. When the equipment arrives at the user’s warehouse, we will send a professional engineer to the site for installation and training. Some users could use WeChat or WhatsApp to contact us for remote installation guidance for some simple machine models. The English version diagram and manual operation book will be delivered with the machine to support users in learning the machine before installation. What’s more, we could also help users in packaging film design works and choosing suitable packaging films to save costs for them.

FAQ About The Pyramid Teabag Packing Machine

What is the pyramid tea bag packing machine?

The pyramid tea bag packing machine is a type of packaging solution to forms the PLA film or Nylon film into triangular or rectangular shapes with tea products filled inside and then repacked into the foil outer sachet automatically. There are different kinds of machine models with different features for options according to each user’s production needs.

How does the pyramid teabag packaging machine work?

The pyramid teabag packing machine is normally composed of the tea leaf dosing filling system, inner teabag packaging system, and outer sachet packaging system. The user could manually feed the material into the hopper of the dosing machine, then the inner teabag packaging system shall pull the film and form into shapes. When the material is filled into the inner teabag, the machine shall ultrasonic seal the inner teabag and then insert it into the outer sachet for the wrapping packaging process. Finally, the heat-sealed outer sachet shall be output directly.